57

PERIODICAL INSPECTION AND MAINTENANCE.

7/71, 12/56

Fuel System Air Bleeding

The entry of air into the fuel system will cause difficult engine starting

or engine malfunction.

When carrying out service procedures such as emptying the fuel

tank, draining the filter/separator, and changing the fuel filter element,

be sure to bleed air from the fuel system.

Air bleeding method:

’At fuel filter’

Loosen air bleed screw D (fig. 16).

Operate supply pump priming lever E until fuel flow is free of

bubbles.

Tighten bleed screw D, continue operating priming lever until

pumping action is not felt.

Start engine and check for leaks

’At injection pump’

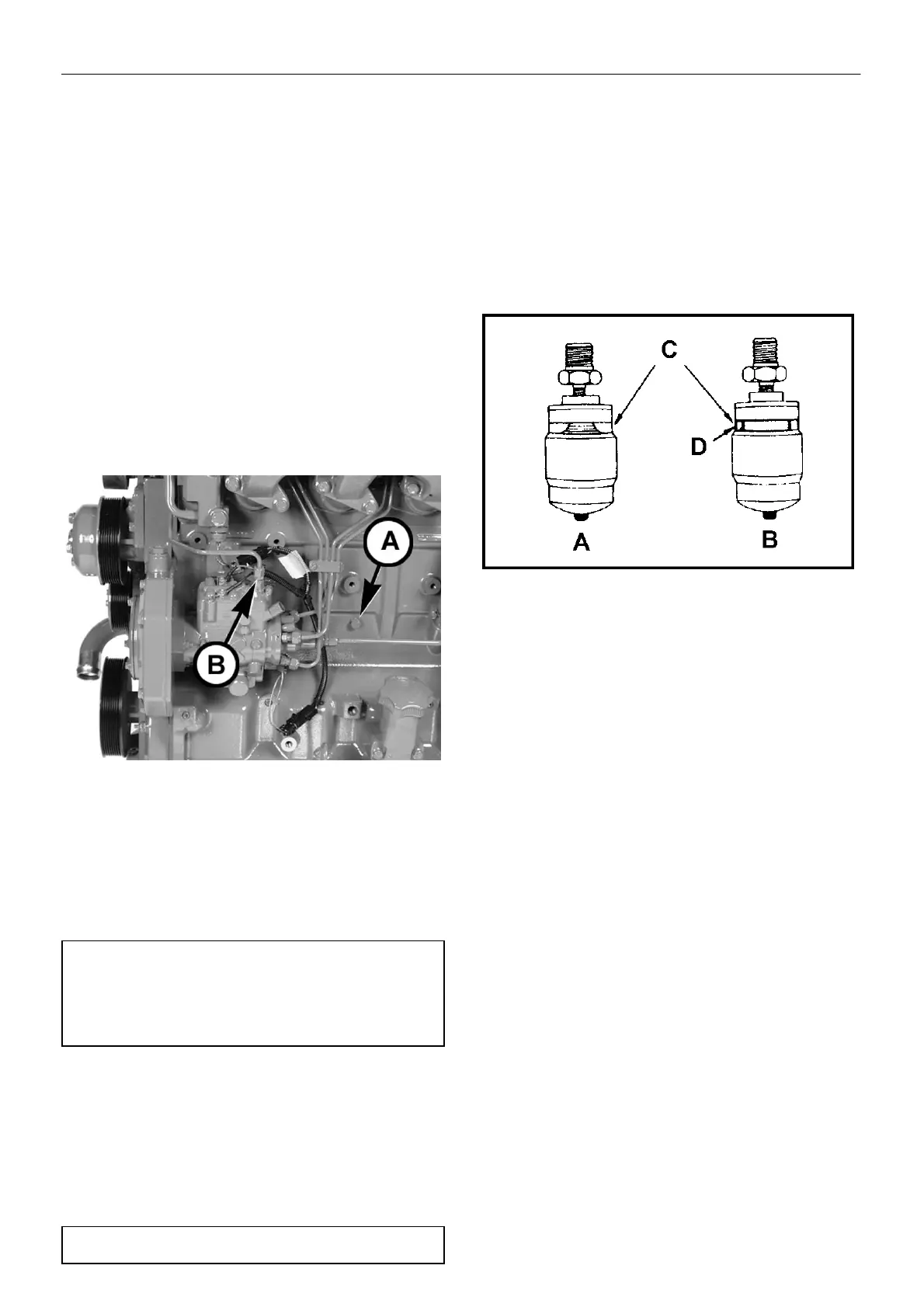

Fig. 17

Slightly loosen fuel return line connector B (fig 17).

Operate supply pump priming lever E until fuel flow is free of

bubbles.

Tighten return line connector to 27Nm.

NOTE:

Air can also be bled by use of the primer pump facility in the

filter/separator assembly.

By unscrewing the plastic primer pump head ‘A’ and stroking it up and

down, any air bubbles in the system will be purged back to the fuel tank.

When this has been completed, the pump head must be screwed back

into the filter/separator assembly

Start the engine and visually check the fuel system for leaks.

Governor Control Seals

As the governor is precisely adjusted, most of the controls are

sealed, please do not break them. Should any adjustment be

necessary, contact your local Doosan branch or distributor.

NOTE: Doosan will not accept any warranty claim on an engine

with broken governor seals.

AIR INTAKE SYSTEM

Air cleaner

Engine performance and life vary with the air intake conditions.

A dirty air cleaner element reduces the amount of intake air, causing

reduced engine output and possible engine damage.

Also, a damaged element leads to abrasion of cylinders and valves,

resulting in increased oil consumption, reduced output and shortened

engine life.

The filter element should be changed at 500 hours or 6 months,

whichever comes first, or sooner if the restriction indicator shows red.

See below.

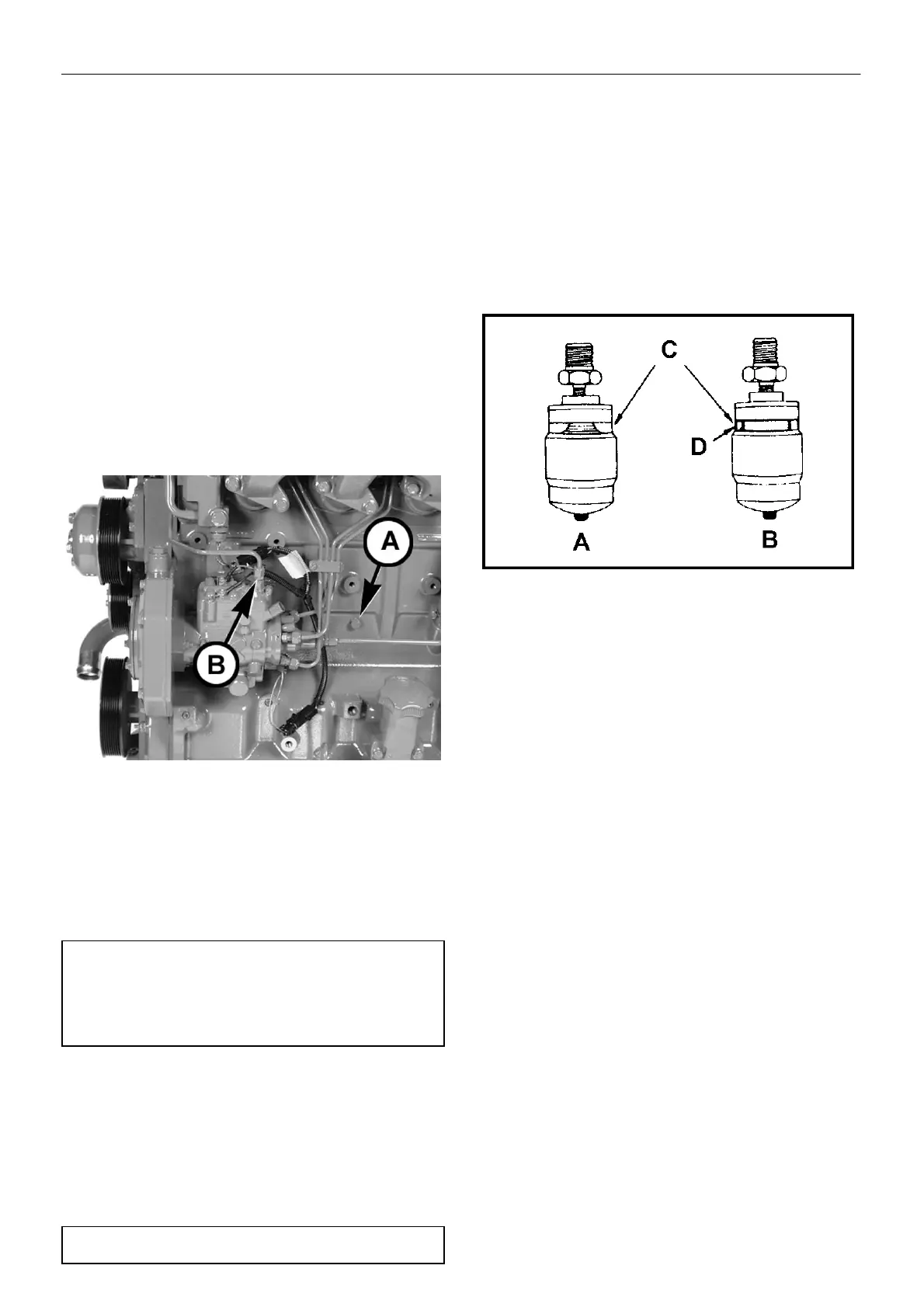

Fig. 18

A Normal

B Clogged

C Indicator

D Red signal

Air cleaner with dust indicator

This indicator is attached to the air cleaner. When the air cleaner

element is clogged, air intake resistance becomes greater and the dust

indicator signal turns to red indicating the element needs to be

changed.

When the signal turns to red, replace the element. Then press the

dust indicator button to reset the indication.

ENGINE ELECTRICAL

The Doosan engines uses a 12 volt system and a negative grounding

for the electrical system.

Battery Servicing

Battery terminal connections

Check the battery cable connections for looseness or corrosion.

Poor cable connections will result in difficult engine starting or

insufficient battery charge.

The battery cables must be tightened securely.

Never reverse “+” and “−” terminals when reconnecting cables

after removal. Even a short period of reverse connection will

damage the electrical parts.

Cleaning of Battery

When the battery terminals are fouled clean them with clean tepid water

and wipe with a dry cloth to remove the water. Apply a light coat of

vaseline or a grease.

Alternator Servicing

The polarity of the alternator is negative (−) grounding type.

Loading...

Loading...