DORMA AUTOMATICES, Inc. 924 Sherwood Drive Toll-Free: 877-367-6211 Subject to change without notice

DL3463-050 08/2016 Lake Bluff, IL 60044 Fax: 847-249-3999

ED100 / ED250 SERVICE MANUAL

—

17

Spring setting revolutions – recorded

ED100

ED250

3

Set spring tension

When system is delivered, spring tension is relaxed.

Spring has to be pretensioned – a minimum of ten revolutions

are required to operate system.

System checks spring tension adjustment during learning cycle.

Cycle will be canceled if spring is insufficiently tensioned.

If spring tension is changed, a new learning cycle

must be performed.

Spring is adjusted at factory for fully

counterclockwise position – no spring tension.

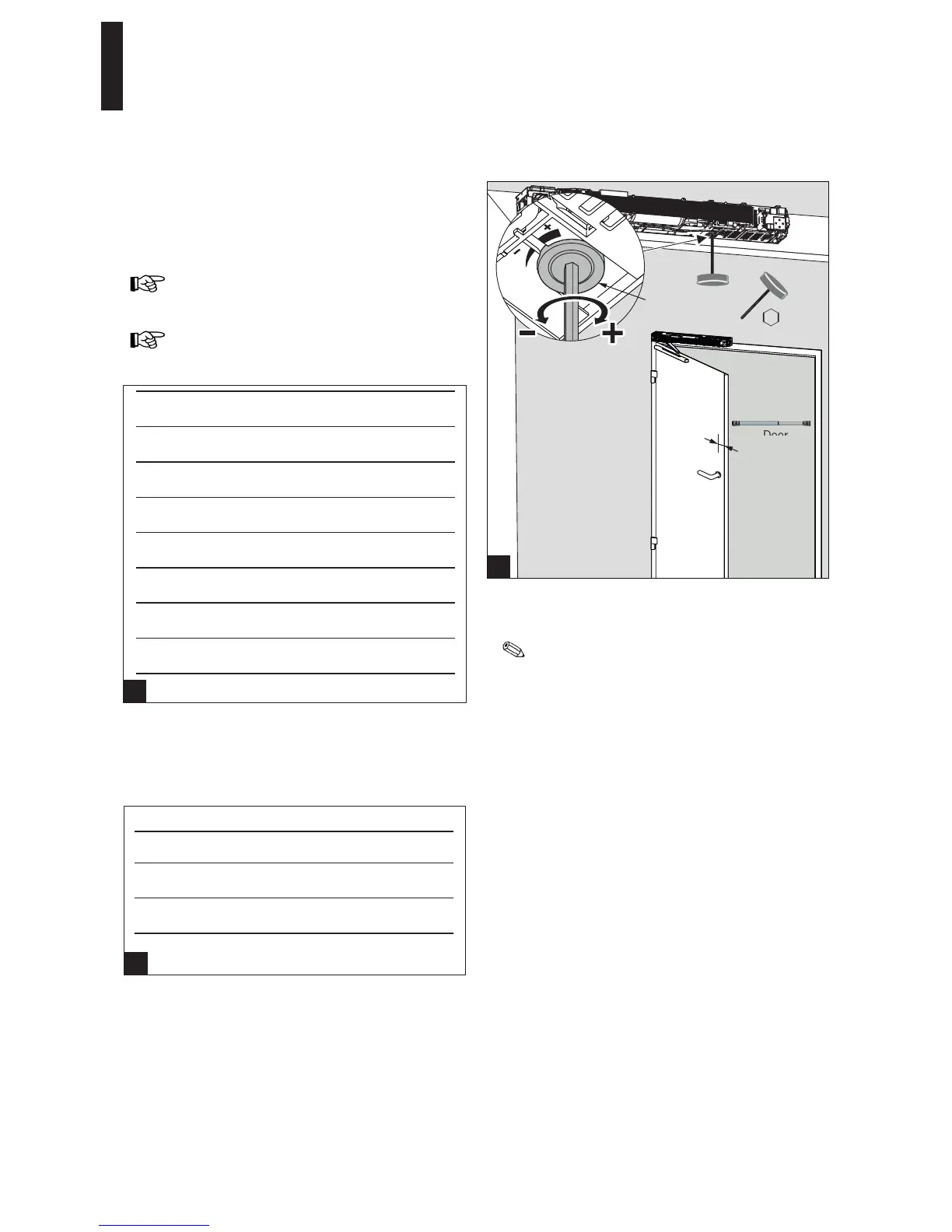

Table I

Door width

inches 32 36 42 48 55

mm 813 914 1,067 1,219 1,397

Spring setting revolutions

ED100 10 14 16 -- --

ED250 -- -- 14 18 24

1.1 Operator spring tension – refer to Table I for required

number of full revolutions.

2.1 Adjust spring tension using a 5 mm hex T handle.

3.1 Record spring setting revolutions.

1

5 mm

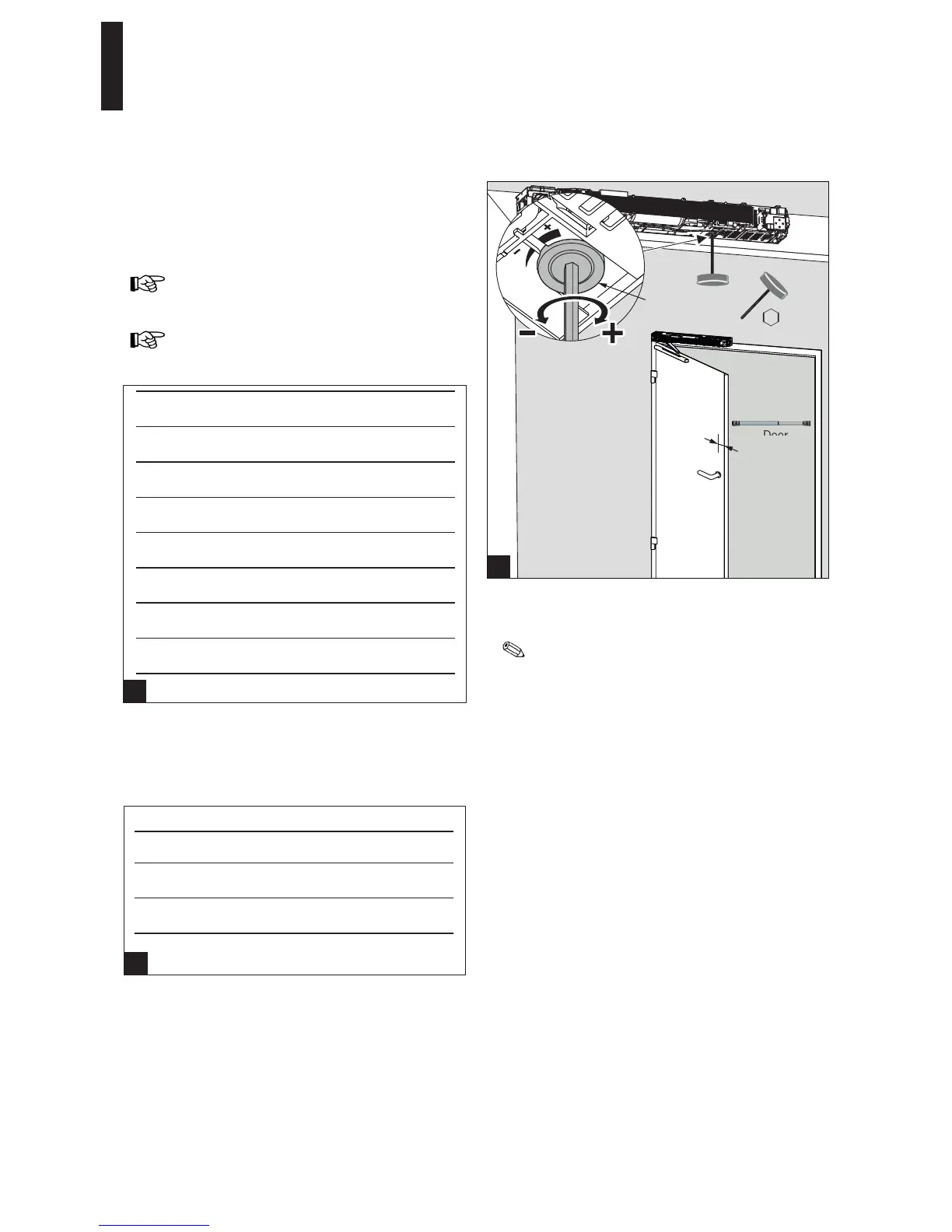

Door

pressure

gauge

Spring tension

adjustment

Measure force 1”

[25 mm] from lead

edge of door

1”

[25 mm]

Table I indicates approximate values – use door

pressure gauge to check closing force at 2° and

adjust if necessary. Refer to Sections 14 and 15 for

values.

For reveal depths greater than 11 5/16" [300 mm],

also check minimum closing force between 88° and

92°.

2

12. Set spring tension

Loading...

Loading...