50

ED50/ED100/ED250 09-2021DL4617-003

dormakaba ED50/ED100/ED250 OHC Header

Setup and Troubleshooting Instructions

Chapter 21

. ED/ED/ED environment and cleaning

.. ED/ED/ED environmental

requirements.

ED/ED/ED overhead concealed header

assembly is designed to operate on an interior building

surface under the specifications shown in Table ...

.. Areas around door(s) and door swing radius.

Areas around doors and door swing radius must be kept

clear of all obstacles.

.. Cleaning

WARNING

Cleaning of header surfaces must be done with

program switch in Close position!

External surfaces of the header can be cleaned with a

damp cloth and commercial cleaning agents.

TIPS AND RECOMMENDATIONS

Abrasive (scouring) agents should not be used

as they may damage external header surfaces.

.. Water and other liquids.

CAUTION

No water or other liquids must be sprayed or

spilled on ED50/ED100/ED250 OHC header!

Table .. Operator environmental requirements

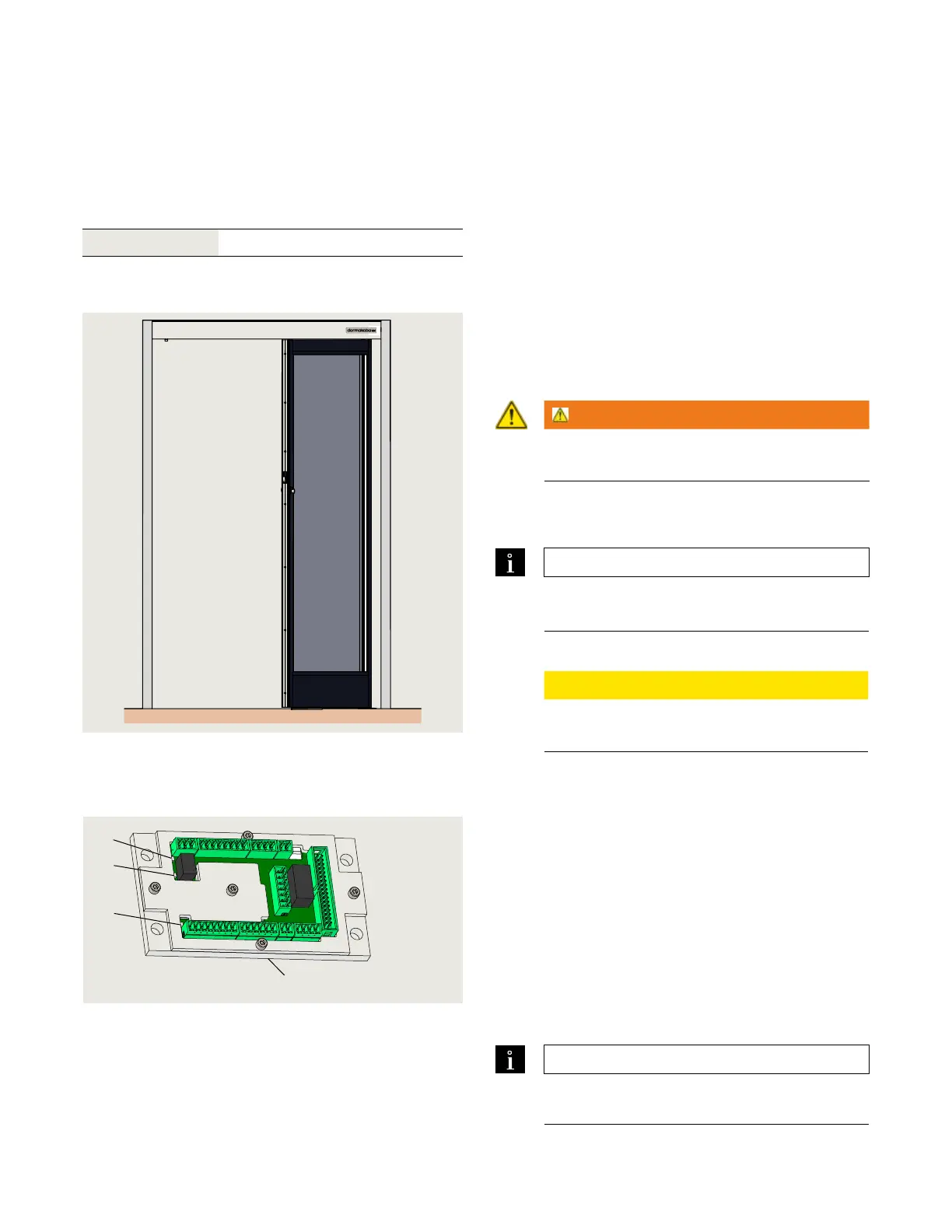

Fig. 21.1.1 ED50/ED100/ED250 OHC header and

LH door

Ambient temperature to °F

21.2 Operator status LEDs, maintenance interval

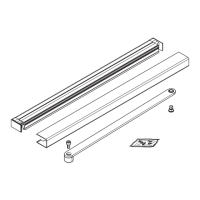

Fig. 21.2.1 Operator status LEDs

.. Operator status LEDs, maintenance interval.

Header cover must be opened to view LEDs, located on

accessory wiring terminal board.

. Red LED

Blinking codes are used to indicate "ln__" information

(system status or operating conditions) or certain

error codes "E__".

. Yellow LED

Maintenance interval indicator. When illuminated, an

indication the operator system has to be serviced.

. Green LED

• On, internal Vdc power is On.

• Off, internal Vdc power is Off.

TIPS AND RECOMMENDATIONS

Details on LED status codes: Appendix B.2;

Troubleshooting.

1 Red LED

2 Yellow LED

3 Green LED

4 PCB assembly

5 Accessory terminal

board

5

3

2

1

Maintenance

Loading...

Loading...