MAINTAININ

24 DR

®

ROTO-HOG™ POWER TILLER - OPTIONAL ACCESSORIES

G THE DR CULTI-PACKER

GREASE BEARINGS

aft.

is recommended. More

usty conditions.

2. Repair or replace parts if necessary.

2.

REPLACING WHEELS

1. Loosen both Bearing Set Screws (Figure 34).

4. Slide Axle through Bearings, Frame and Wheels.

Set Screws.

Clea g

2. Clean out any build up of material from the Culti-packer Wheels.

3. Clean any build up of material from your ROTO-HOG Tiller.

Regular Maintenance Check List before each use

1. There are two grease points on the culti-packer. There is a bearing at each end of the wheel sh

Greasing the bearings at least every 4 hours with all purpose grease

frequent greasing may be necessary in very d

CHECK FOR LOOSE FASTENERS

1. Before each use make a thorough visual check of the Culti-packer for any bolts and nuts which may

have loosened. Retighten any loose bolts and nuts.

CHECK FOR WORN OF DAMAGED PARTS

1. Check for worn or damaged parts before each use.

Replacing Parts

REPLACING BEARINGS

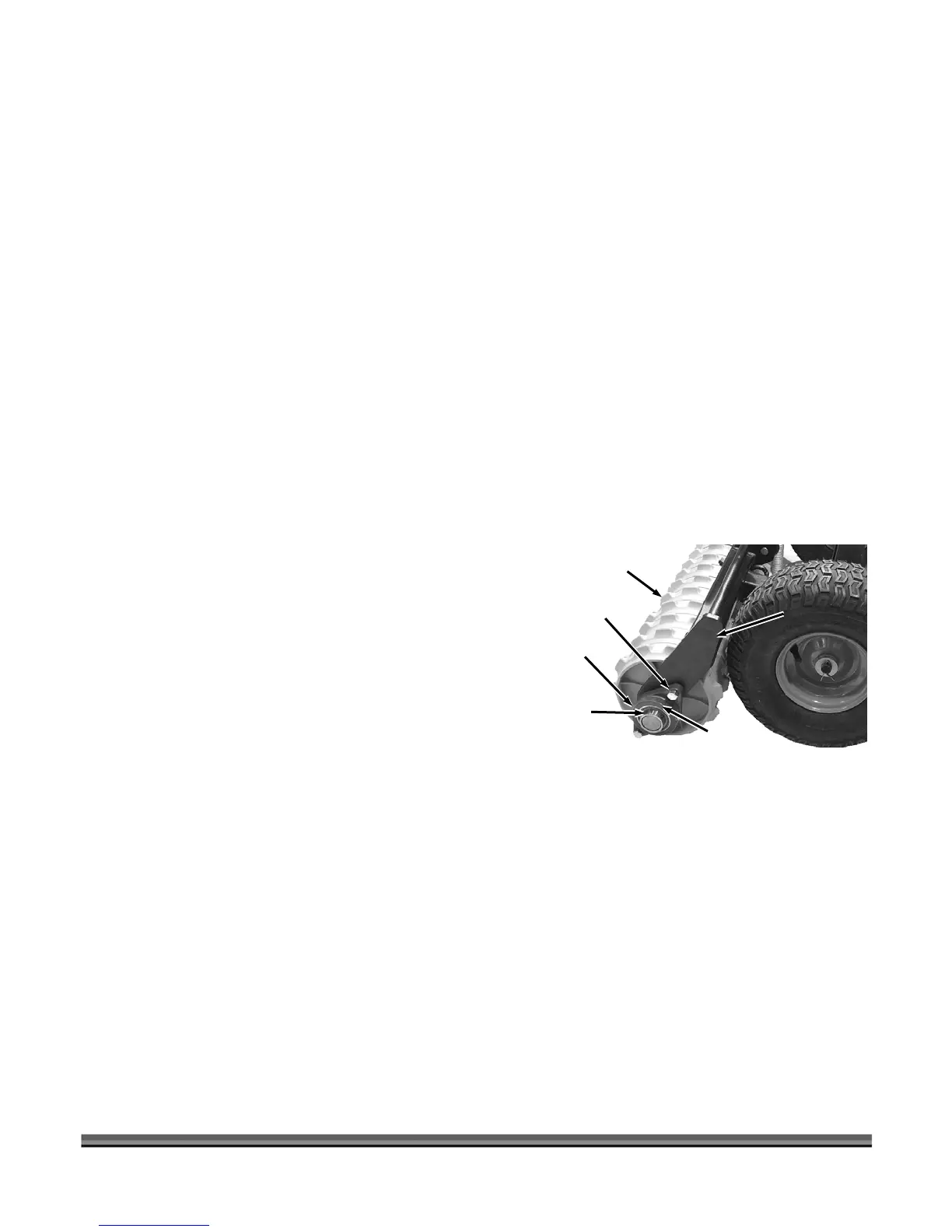

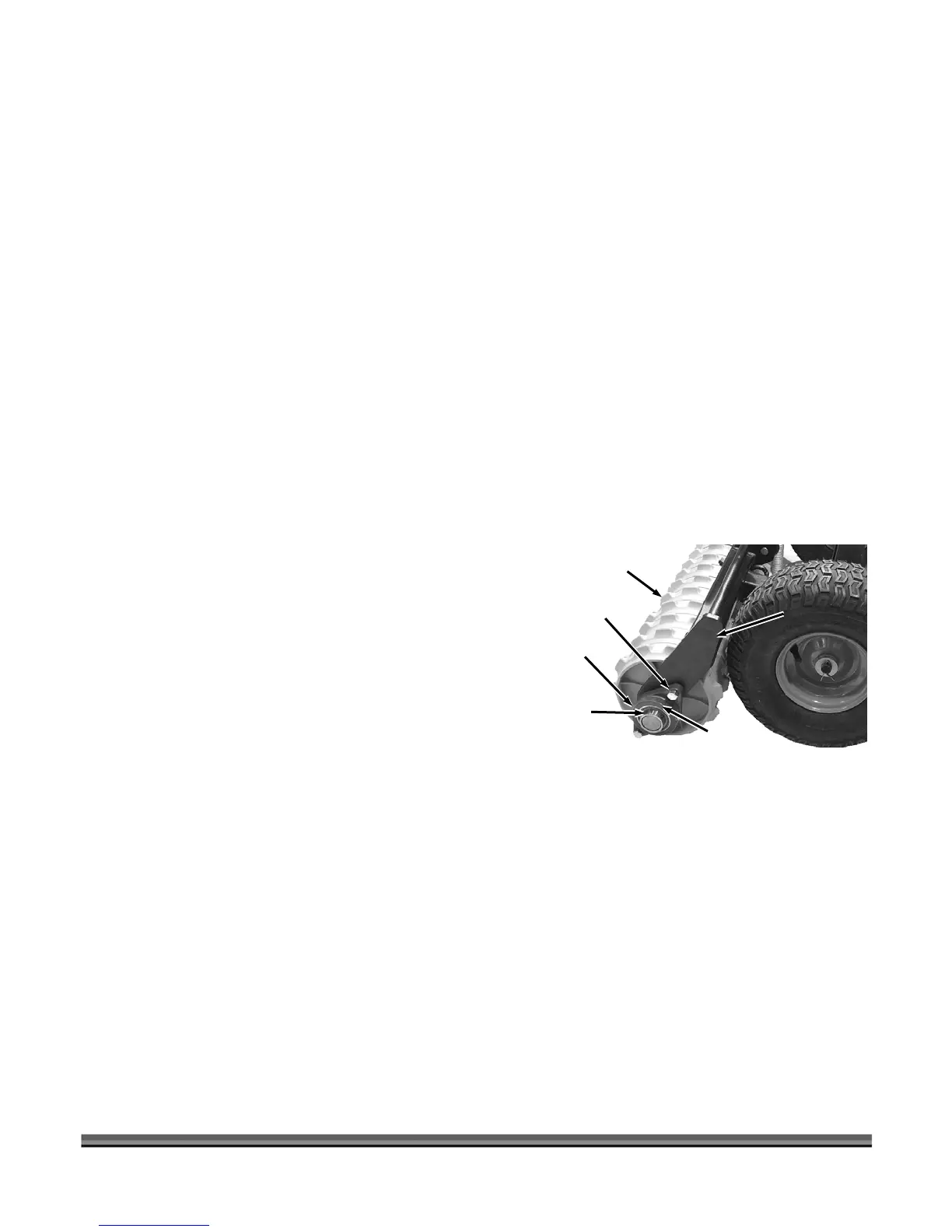

1. Loosen the Bearing Set Screw (Figure 34).

Remove the Bolts and Washers then remove Bearing.

Culti-packer

Wheel

Bearing

Bolts and

Washers

Set Screw

Frame

Axle

3. Position the new Bearing Over the Axle.

4. Install Bolts and Washers.

5. Tighten the Set Screw.

2. Slide the Axle from the Bearings, Frame and Wheels.

3. Replace damaged Wheel with new Wheel.

Figure 34

5. Tighten

nin

1. Rinse the Culti-packer and dry off before storing.

Storage

1. Rinse the Culti-packer and dry off before storing.

2. Store in a clean, dry area.

Loading...

Loading...