Operation

Dräger Polytron 5000 7

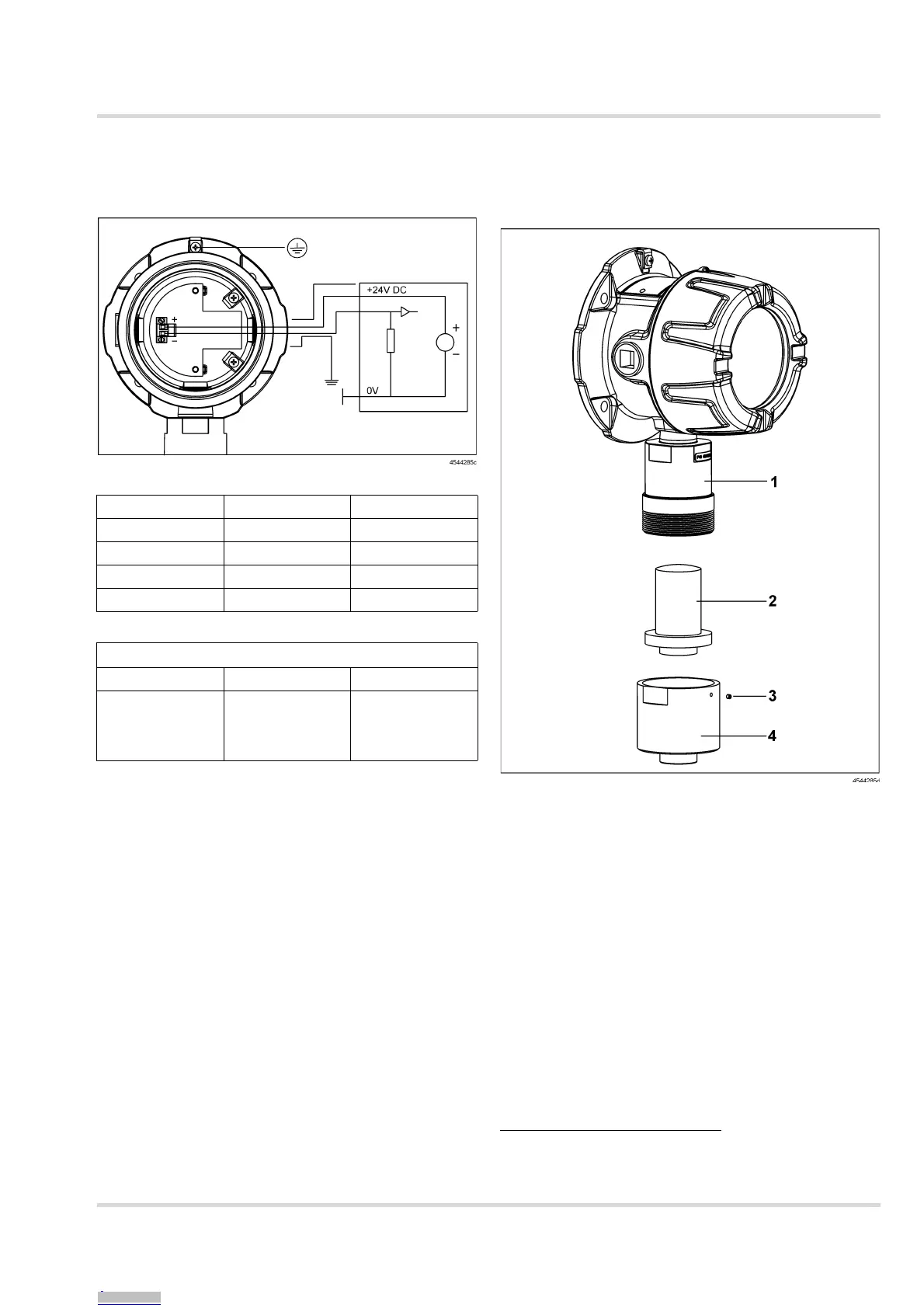

z Connect the wires as shown below.

Secondary circuit intended to be supplied from an

isolating source.

Tightening torque

Tightening torque and wire size for field wiring terminals

z In case of optional increased safety terminal box, securely

screw the transmitter onto the e-box using 4 screws with a

tightening torque of 8 Nm.

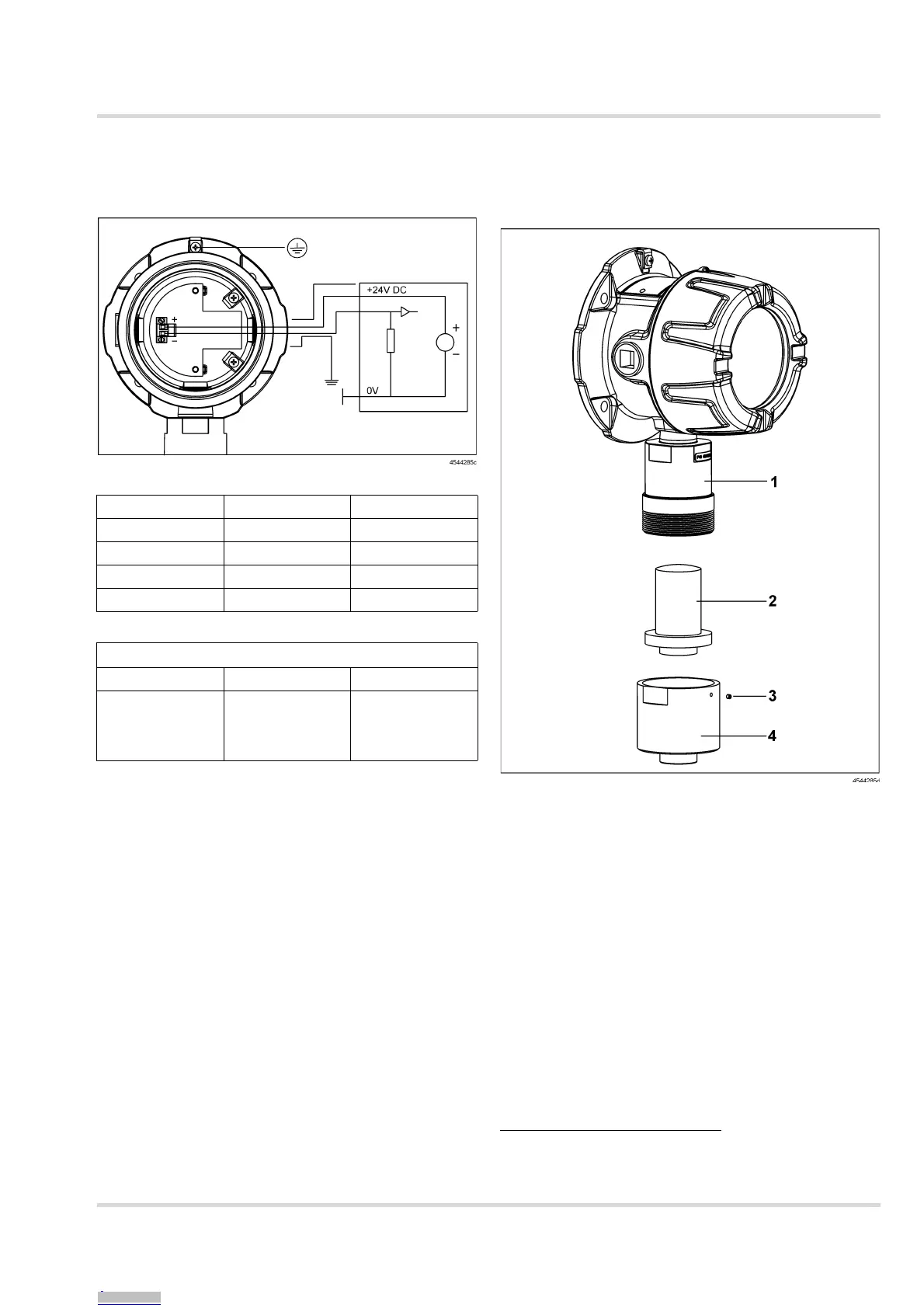

3.3 Installing the sensor

The Polytron 5000 sensor connector is keyed and can only be

installed one way. Use only DrägerSensors in this instrument.

To install the sensor, see the following figure for details:

1 Sensor housing

2 Sensor

3 Set screw

4 Sensor cover

1. Loosen the set screw in the stainless steel sensor cover.

2. Unscrew the stainless steel sensor cover at the end of the

sensor housing.

3. Insert the ribbon cable connector into the socket in the

DrägerSensor

®1

.

4. Push the DrägerSensor into the sensor housing.

5. Screw the stainless steel sensor cover back on.

6. Tighten the set screw to secure the sensor cover.

7. Allow the sensor to warm-up according to the sensor data

sheets.

z Always test a newly-installed sensor with target gas to

verify proper operation.

z When installed at locations exceeding ambient

temperatures of 55

°C, use only appropriate wiring

specified for at least 25

°C above the maximum ambient

temperature.

Part TQ Lb. In. TQ Nm

lid min. 266 min. 30

sensors min. 266 min. 30

plugs min. 266 min. 30

conduit hubs min. 443 min. 50

Electronic

TQ Lb. In. Wire Size AWG Wire Size mm

2

All field wiring

terminals

4.4 - 7.0

(0.5 - 0.8

Nm)

24 - 12 0.2 - 2.5

1) DrägerSensor

®

is a registered trademark from Dräger

Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.Downloaded from Arrow.com.

Loading...

Loading...