Printed in Germany / M-MT-BOS

• Edition 11.99 • # 231 763

22 … 112

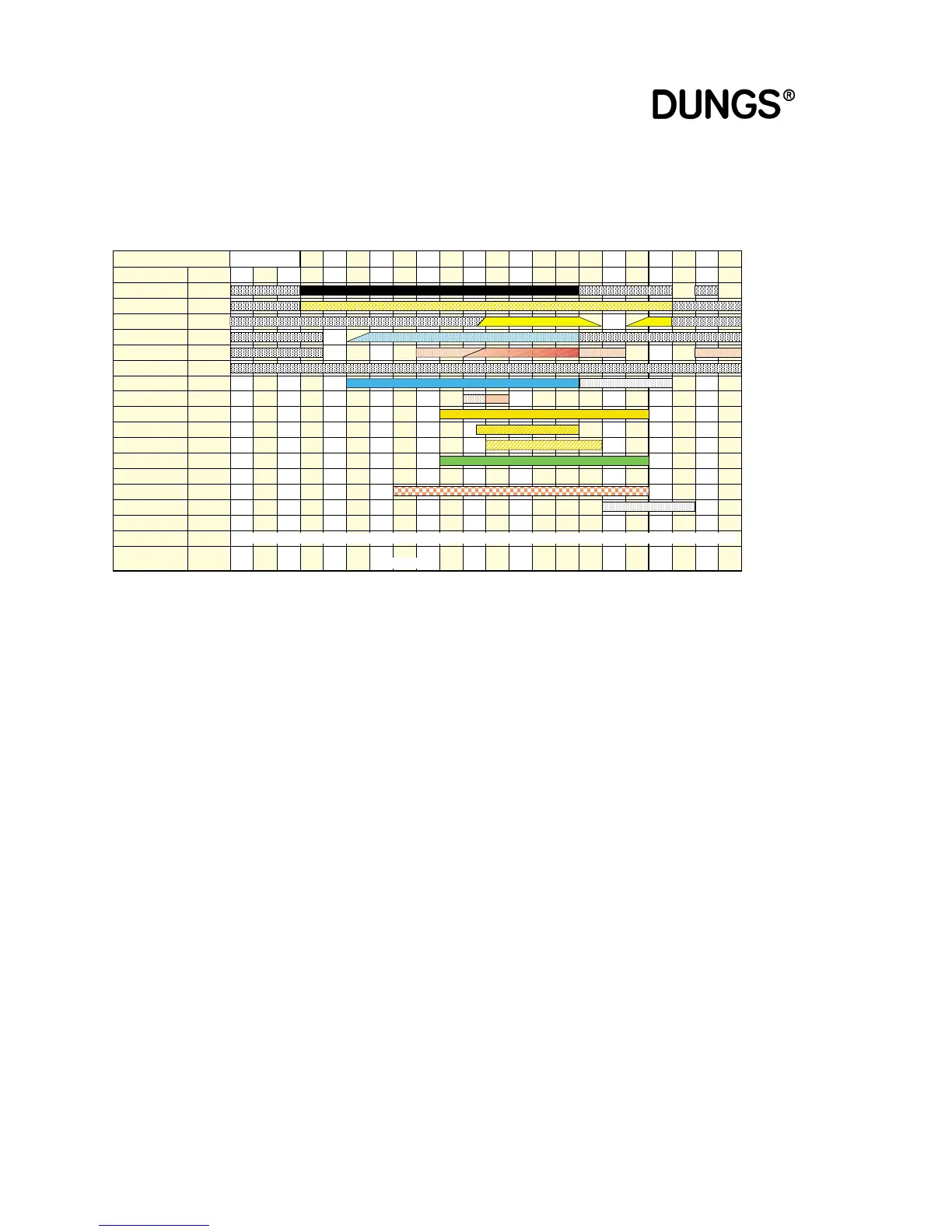

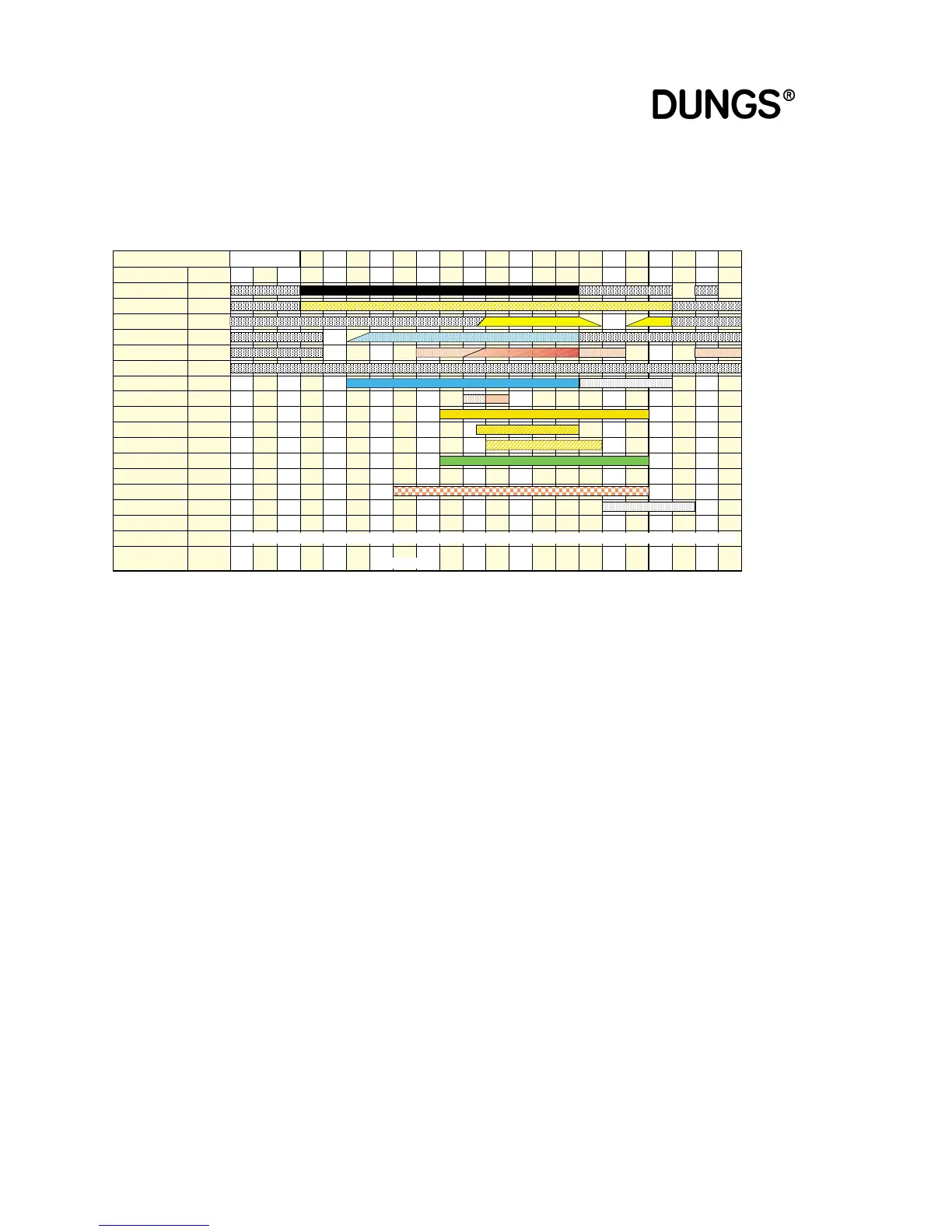

Time diagram

Gas firing, electronic

modulation

Time diagrams for MPA22 gas burner, electronic modulation

Definitions of individual states

Start-up tests Processor and program memory test/move servomotor to reference point

State 01 Start-up decision (heating request issued)

State 02 Idle state check, blower

State 03 Blower start-up

State 04 Pre-ventilation / move servomotor gas over full rotational range

State 05 Pre-ventilation / energize and test watchdog

State 06 Pre-ventilation / move servomotor gas to ignition position

State 07 Move servomotor air to ignition position

State 08 Pre-ignition (depending upon parameters)

State 09 Start-up safety period

State 10 Stabilising time

State 11 Move servomotor from ignition point to operating characteristic

State 12 Operation

State 13 Evacuate VPS valve space / (postventilation)

State 14 Test time Y2 / (remaining postventilation time)

State 15 Fill VPS valve space / (remaining postventilation time)

State 16 Test time Y3 / (remaining postventilation time)

State 17 Remaining postventilation time

State 18 Restart lockout time / wait time loop for gas fail-safe function

State 20 Start-up wait state (standby)

State 21 Postventilation before error

Footnotes:

1* The blower runs during the leakage test until the postventilation period elapses. The servomotor air then enters

standby state.

2* The pre-ignition cycle is started 0, 1 or 2 s before the start-up safety period commences, depending on the setting

in the EEPROM.

3* Valve Y2 (SV) always opens 1s before the start-up safety period commences so the GWmin can detect the

presence of gas pressure.

4* After a controlled shut-down a leakage test is performed on the valves, provided the VPS is active. The VPS flag

is then set to „valid“. If the VPS flag is invalid, e.g. after a power outage or safety shut-down in state 08 to 16, the

leakage test is performed before the main valves are opened.

Start and controlled shut-down with flame and active valve proving system

Test already performed at last controlled shut-down

Start-up tests

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 20

State number

Display

Closed-loop

control sequence

GW max

GW min

Air pressure switch

Flame

GW VPS

Blower motor

Ignition

Valve Y1

Valve Y2

Valve Y3

Operation

Fault

Watchdog

SAD air

SAD gas

VPS flag

Duration

Input

Input

Input

Input

Input

Input

Output

Output

Output

Output

Output

Output

Output

Output

I / O

I / O

Flag

TEST

L G 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 OFF

<3

s

--->Ref

Ref.

P9P9-->P9 P9 P9 -->P0 P0 P0 P0 -->P1

–––

––– –––

--->Ref

Ref. Ref. Ref.

Ref.

P1-P9

–––

->109° 109° P0-->P0 P0 P0 P0 -->P1 P1-P9

––– ––– ––– –––

Stby

–––

Stby

1* -->Stby

Stby

–––

1*depending upon run-on period

2*

3*

<3,5

s

<3,5

s

1

s

<30

s

<10

s

5 0,3 5..55 <30

s

1..2

s

2..5

s

1..60

s

<30

s

<24

h

2

s

1..240

s

1

s

0..100

min

10..60s

1..240

s

1..240

s

<24

h

valid 4* invalid valid

Loading...

Loading...