(27)

Turn on power.

Turn on the ELB and ensure that the yellow LED (beside the dipswitches) lights. The LCD

controller counts down 10 seconds. Refer to Table 5.2 and Figure 5.1.

[NOTE] After turning on power, the instruments warm up for 10 seconds before the pump

will start.

Ensure cooling water flow is 3.5 L/min or more.

Readjust regulator so that dilution N

2

gas is within the range described below.

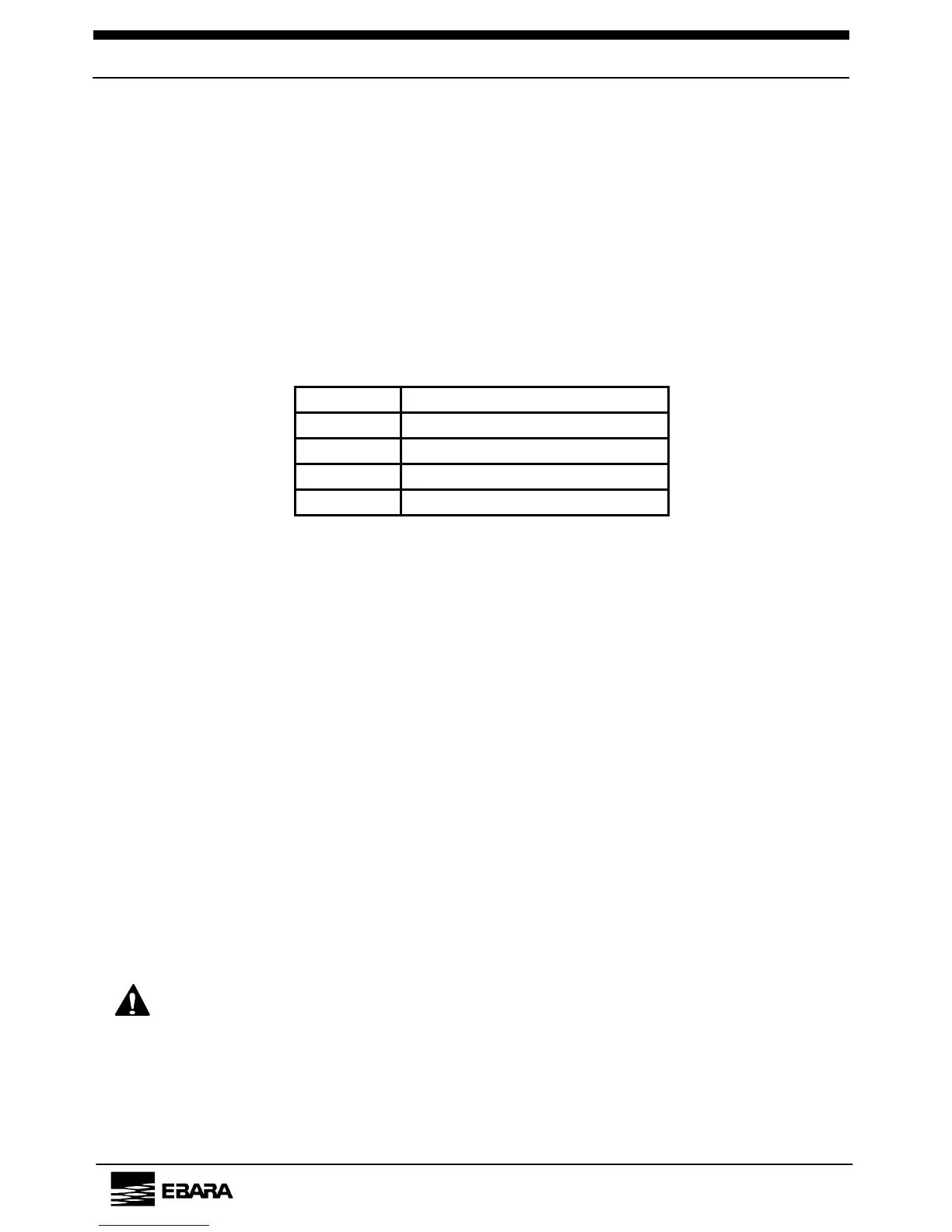

Table 5.1 Dilution N

2

gas flow

A70W 20-24 Pa m3/s

A30W 15-19 Pa m3/s

A25S 14-17 Pa m3/s

A10S 14-17 Pa m3/s

A07V 12-15 Pa m3/s

Then ensure that pressure gauge indicates 0.04-0.07 MPa.

After setting, push the red stopper of knob to lock.

Under this condition, shaft seal N

2

flow rate is 2.7-3.4 Pa m3/s. (Shaft seal N

2

flow rate is

not shown on LCD.)

Check that LCD displays no ALARM/TRIP signal.

The motor current is indicated as "00.0 A" on LCD.

When LCD indicates an ALARM/TRIP signal or an abnormal symptom appears, take

necessary measures in accordance with Section 8.

[NOTE] ALARM/TRIP signal persists until entry of a RESET signal even if the causes are

remedied.

After taking necessary measures, either press the RESET switch on the LCD

controller or input RESET signal through the control connector.

When buzzer is in use, pressing BUZZER OFF mutes the buzzer despite an

ALARM/TRIP condition.

Open the valve on the exhaust piping before starting the pump.

If the system has an exhaust gas scrubber, open its inlet and outlet valves.

CAUTION

Operating pump with these valves closed will pressurize the

exhaust and overload the pump.

EBARA Corporation

Loading...

Loading...