A313-01-880 Issue A

Page 32 © Edwards Limited 2008. All rights reserved.

Edwards and the Edwards logo are trademarks of Edwards Limited.

Maintenance

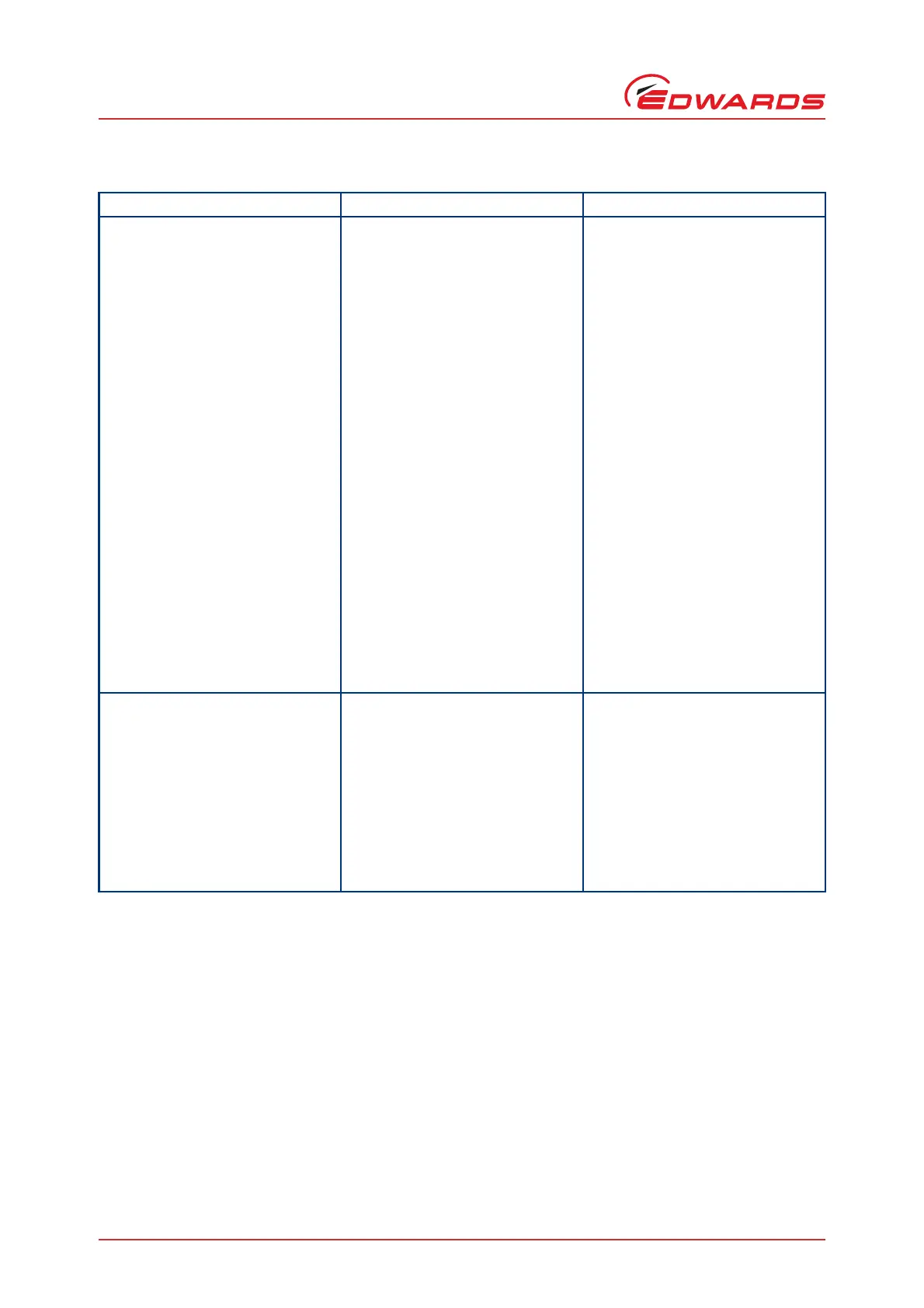

Table 12 - Fault finding

Symptom Check Actions

The pump will not start, or seizes

during operation.

Has the pump been overloaded? Check the required operating

conditions and specified

performance of the pump (see

Section 2).

Has debris or foreign material

entered the pump?

Strip down, clean and repair the

pump as necessary.

Is the motor or drive/transmission

system faulty?

Check that your motor or drive and

transmission system is operating

correctly, and that it is correctly

fitted to the pump: refer to the

Motor Manual supplied and to

Section 3.7.

Has the pump casing been distorted? Check that the pump is installed on a

level surface (see Section 3.2), and

that the maximum loadings on the

inlet/outlet flanges have not been

exceeded (see Section 3.11).

Rectify any problem found, then:

Check the pump casing for

distortion. If the casing is distorted,

contact your supplier or Edwards for

advice.

If the casing is not distorted, check

the rotor clearances. Contact your

supplier or Edwards for advice.

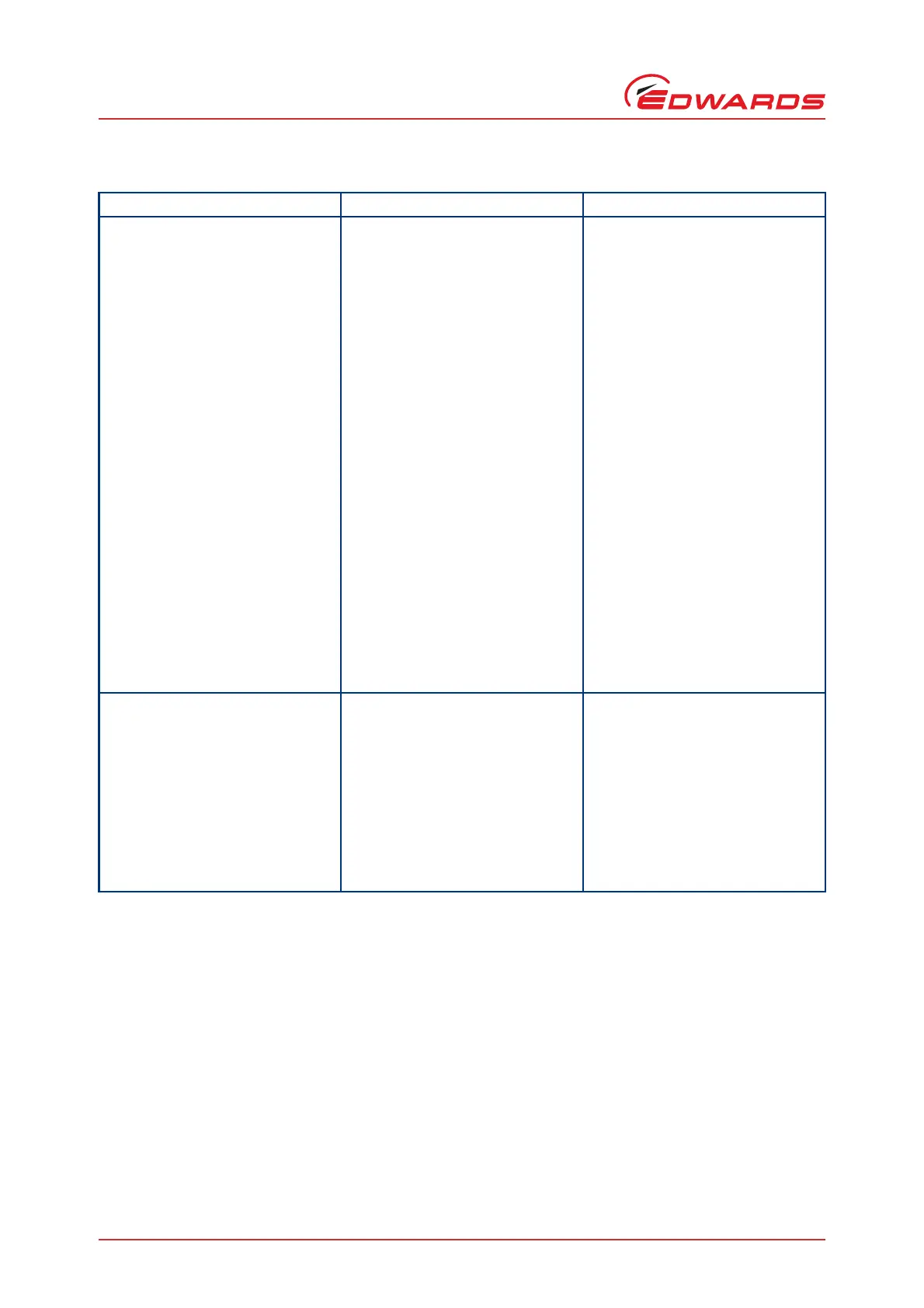

The pump is noisy during operation. Are the rotors touching, or are the

rotors striking the pump casing?

Check the rotor clearances and

rotor-compression chamber

clearances. Contact your supplier or

Edwards for advice.

Is gear backlash excessive? Check the gears and replace if

necessary.

Are the gear and/or bearing

clearances incorrect?

Check the clearances. Contact your

supplier or Edwards for advice.

Are the rotors unbalanced? Contact your supplier or Edwards for

advice

Loading...

Loading...