Instruction Manual

3 Putting into Service

Before putting the control into service, the following must be ensured, checked and/or adjusted:

The correct installation of the drive, position transmitter and accompanying devices, if necessary

The correct selection of the trimming operation using parameter 290

If necessary, the correct adjustment of the direction of motor rotation using parameter 161

The correct selection of the functions of keys (inputs) using parameters 240...249

The setting of the transmission ratio between motor shaft and machine shaft using parameter 272

The setting of the type of position sensor using parameter 270

If necessary, the setting of the number of angular degrees after the sensor position using parameter 271

If necessary, the setting of the positions using parameter 171 (possible with all settings of parameter 270)

The correct positioning speed using parameter 110

The correct maximum speed compatible with the sewing machine using parameter 111

The setting of the remaining relevant parameters

Begin sewing in order to save the set values

4 Top part detection

In machines equipped with a top part detection module (OTE module), all parameters needed for the sewing

process are set according to the values stored in the module.

Whether an OTE module is present and, if so, which module, is tested each time the power is turned on.

Depending on the result of the test, different messages appear on the display of the control panel, and different

operations are possible and/or required:

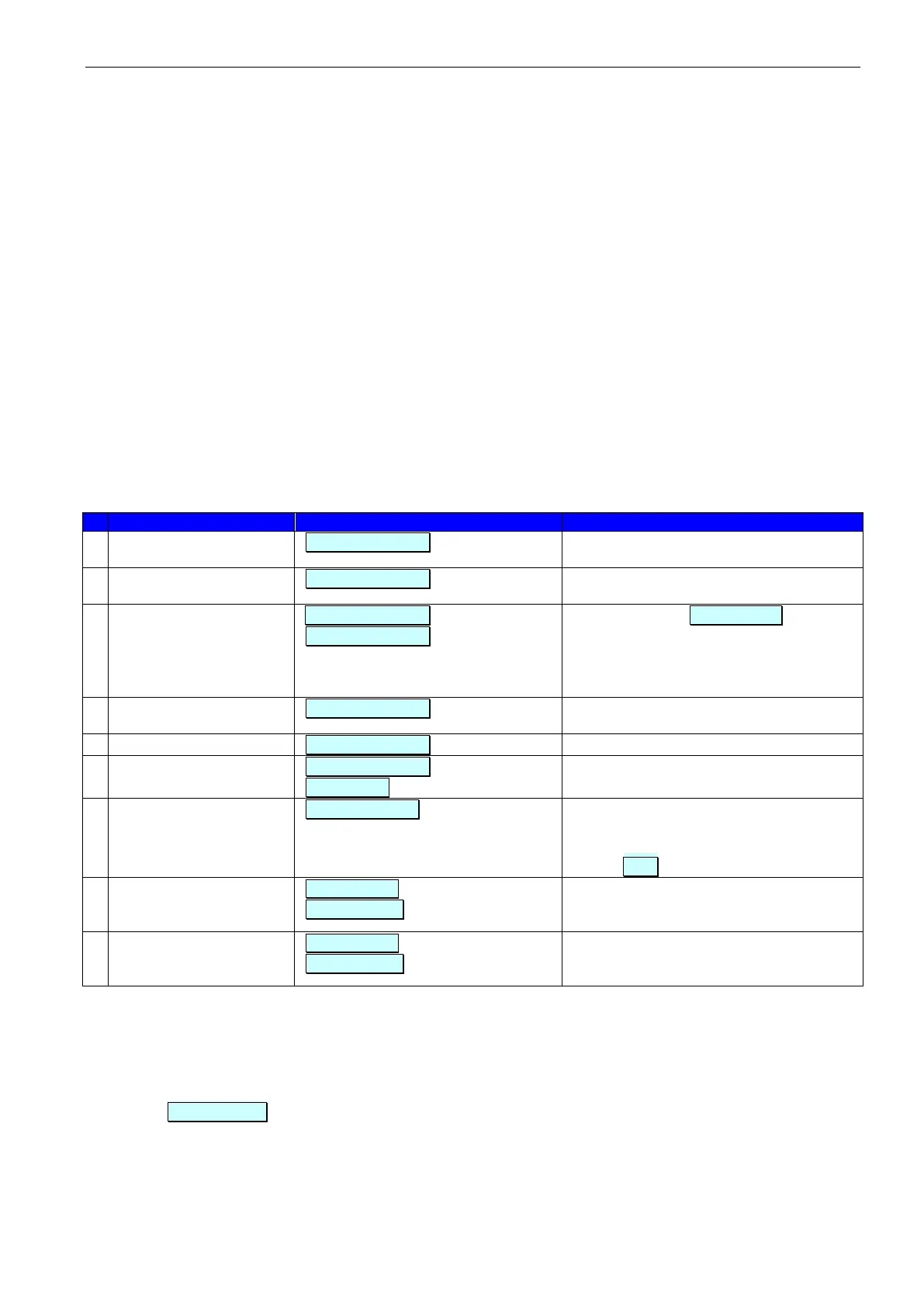

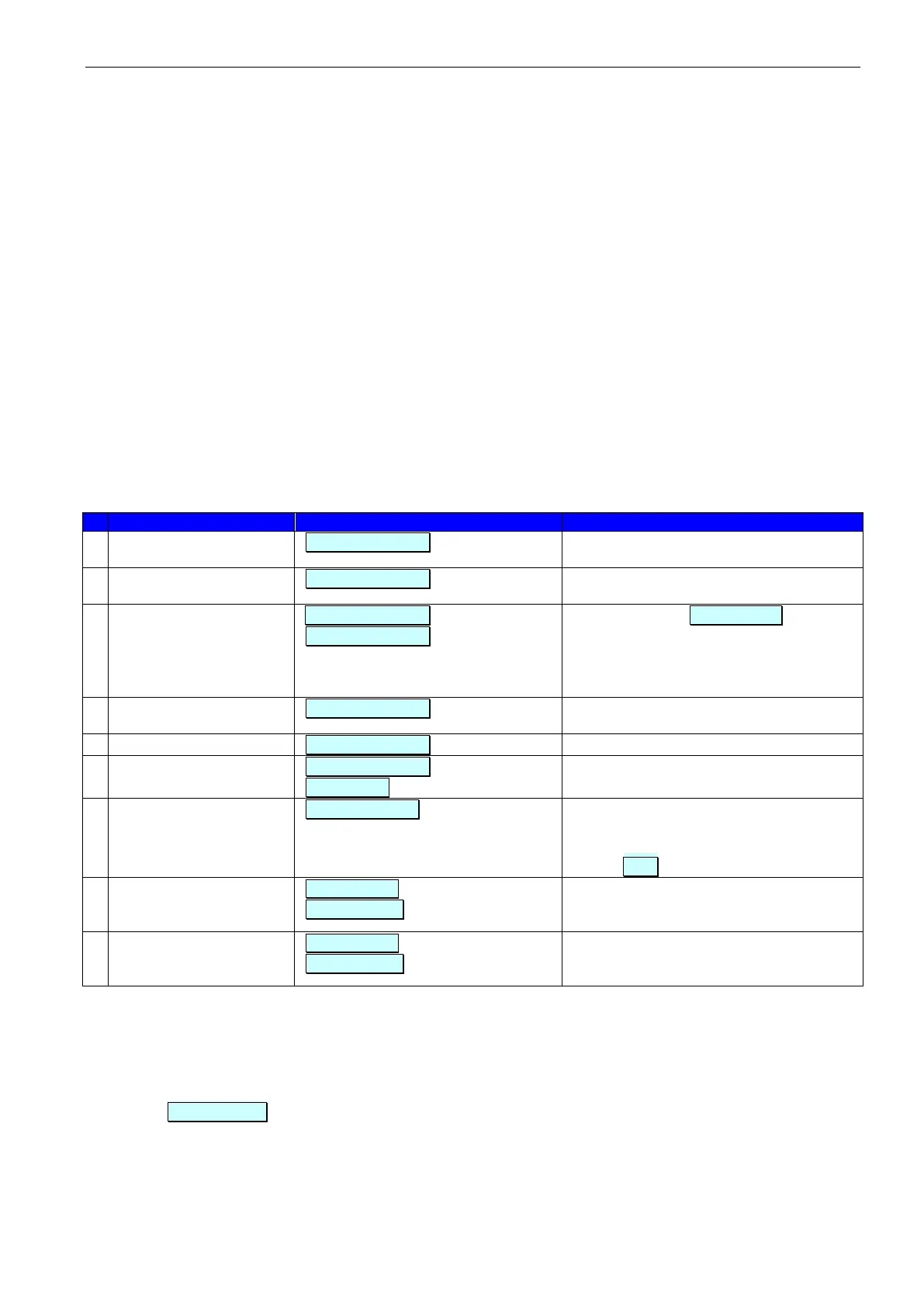

Display on the control panel

Further sequence / options

The PF321A control type

is correctly detected

Sewing process released with the

parameter read out of the OTE module

Sewing process released with the

parameters set in the control

SP74D control type

detected

id wrong (2 sec.)

ote format 0

0 = do not format iLL idEnt .

All functions remain disabled

1 = format with the parameters read out of

the control.

Continue with # 7

No valid control type

detected

All functions remain disabled

All functions remain disabled

crc bAd (2 sec.)

nEw IdEnt

After P or E key, continue with # 7

Select machine class. After automatic

setting of the parameters in question, it is

necessary to determine the transmission

ratio Pully

*1)

.

Program ID of control

more recent than that of

the OTE module

nEw ProgId (2 sec.)

otE updAtE

0 = do not overwrite OTE

1 = overwrite OTE with the parameters

read out of the control.

Program ID of control

older than that of the

OTE module

oLd ProgId (2 sec.)

otE updAtE

0 = do not overwrite OTE

1 = overwrite OTE with the parameters

read out of the control.

The possible options (e.g. 0 or 1) are selected by pressing the + / - keys on the control panel. Confirmation with

the P or E key.

*1)

To determine the transmission ratio, the pedal must be pushed fully forwards. The drive runs at a reduced

speed until the transmission ratio has been determined, then releases the pedal controlled speed. The

display Pulley goes out.

It is also possible to format a top part detection module using parameter 850.

Loading...

Loading...