DK50

NP-DK50 simple s DE-4_06-2020 - 28 - 06/2020

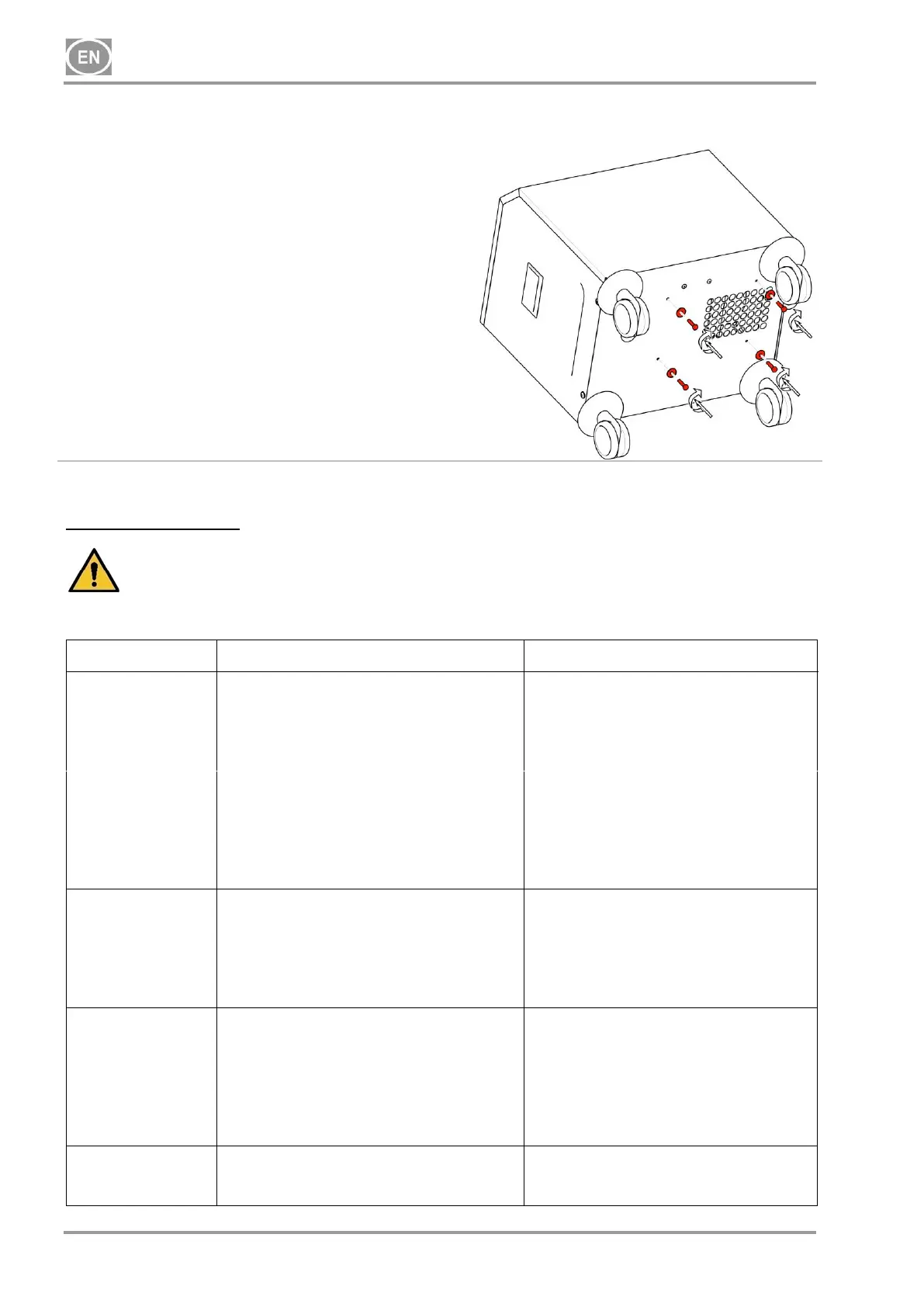

18.7. Stabilizing the compressor before shipping

Before shipping, the compressor must be

stabilized to prevent movement. Prior to fixing it is

necessary to disassemble housing using 4x

screw M5 at side walls of the product. The air

pump must be fixed to the base using four

original screws M6 (see picture) and plastic cover

assembl.

TROUBLESHOOTING

Troubleshooting can be performed only by qualified personnel.

Compressor does

not start

No voltage in pressure switch

Check fuse – replace faulty one

Loosen terminal – tighten it

Check power cord – replace faulty

one

Disconnected winding of motor,

damaged thermal protection

Faulty capacitor

Seizure of piston or another rotary part

Pressure switch is not switching on,

switch switched to “0“ position

Replace motor or re-wind it

Replace capacitor

Replace damaged parts

Check the function of pressure switch

Compressor often

switches on

Air leak in pneumatic distribution

system

Leaking non-return valve

Greater volume of condensed liquid in

pressure vessel

Check pneumatic distribution system

– seal loose joint

Clean valve, replace seals, replace

valve

Drain condensed liquid

Prolonged

running of

compressor

Air leak in pneumatic distribution

system

Worn piston ring

Contaminated filter

Defective solenoid valve

Check pneumatic distribution system

– seal loose joint

Replace worn piston ring

Replace contaminated filter with the

new one

Repair or change the valve

Compressor is

noisy (knocking,

metal noises)

Damaged bearing of piston, piston

rod, motor bearing

Before proceeding, depressurize the air tank to zero and disconnect the device

from the mains.

Loading...

Loading...