8. MACHINE ORIGINS ELBO CONTROLLI

srl

Preset E346+/V+

23

8. MACHINE ORIGINS

8.1 NC MACHINE ORIGINS

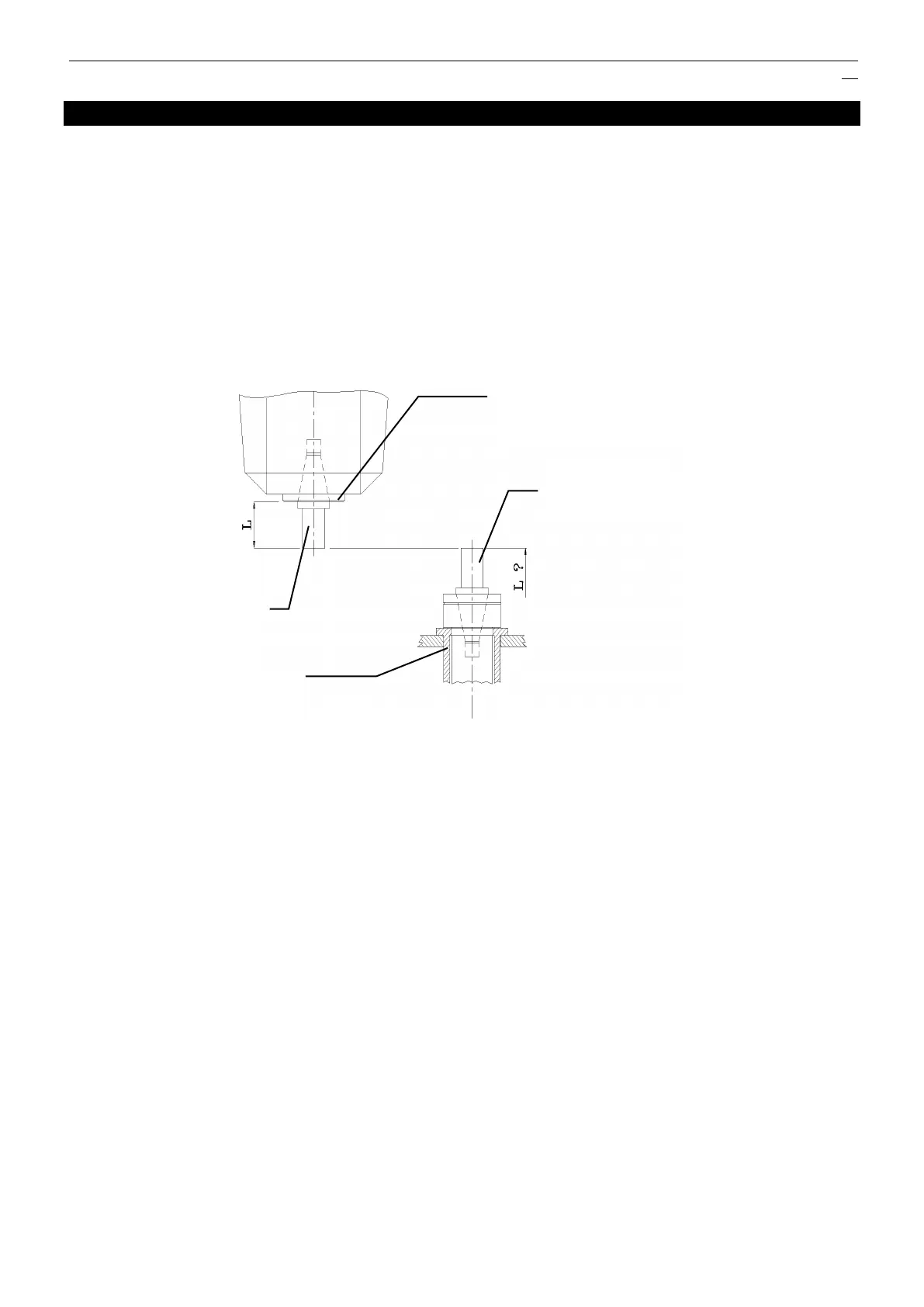

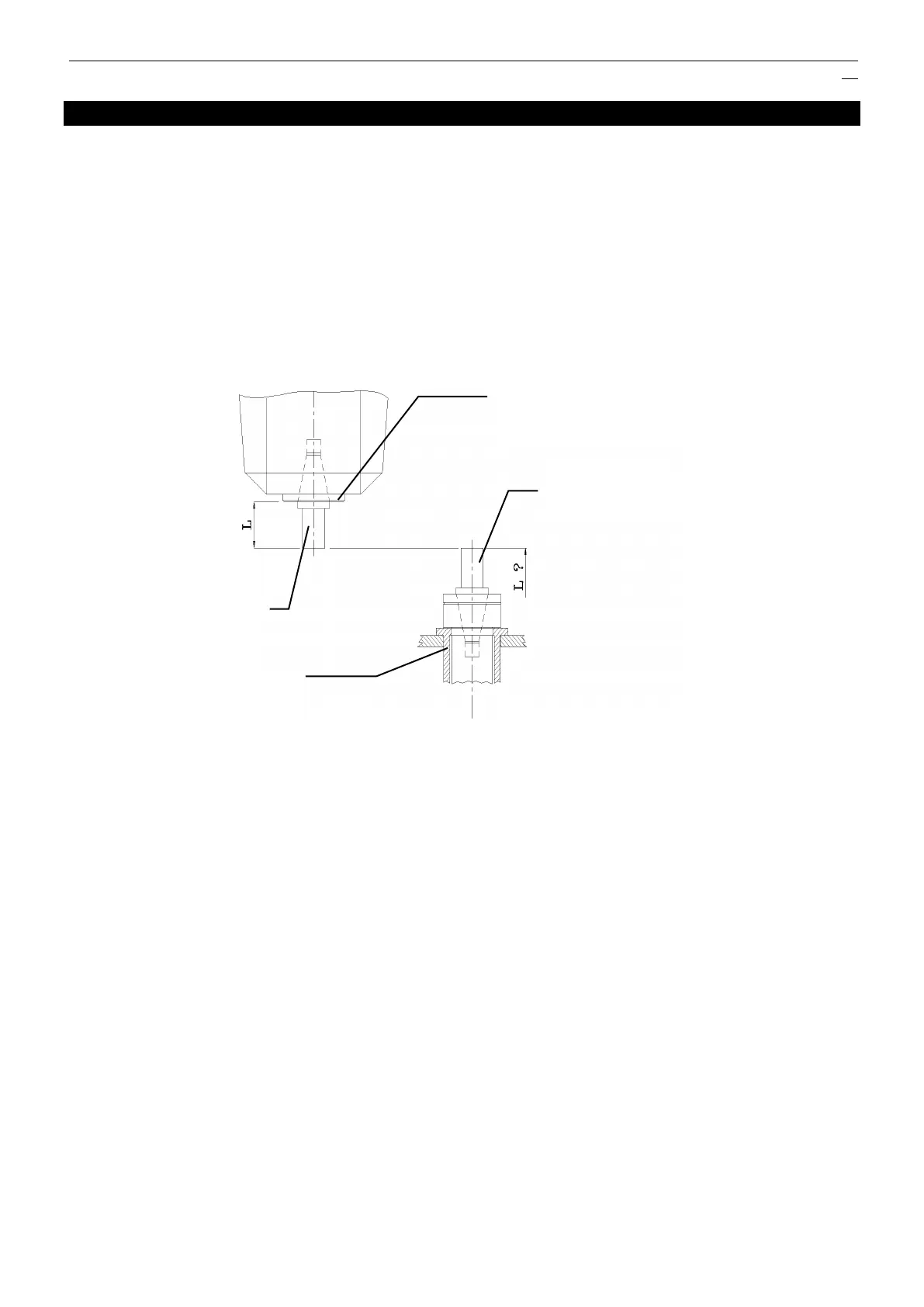

It is important to say that in tool measurement operations, there are no particular problems for the X axis

radial measurements, but a conventional reference point must be established for length (Z axis)

measurements. When a tool radius or diameter is measured, the zero point will always be located on the

tool, though the situation is quite different for length measurements. For this reason, the tool presetter

must be reset on the same point for the Z axis of this NC machine (absolute machine zero-point, spindle

nose, etc.).

One method is to measure a resetting gauge or a reference tool directly on the NC machine, to transfer the

value to the tool presetter in correspondence to its length and set the values on the display.

A more efficient system is to use the same origin given by the length marked on the reset gauge, for all of

the machines having the same spindle intersection.

The electronic equipment 212S of E346+/V+ presetter allows you to choose which system to use in order

to express the length on the Z axis and includes, in preset functioning, the self-learning function of the

origins for each machine or group of machines according to the system applied.

It is possible to specify, for every origin, if the tool corrector has to be expressed as a radius or as a diameter,

the unit of measurement and even the counting direction or the exchange of single axis (very useful settings

for lathe tools measurements).

All settings saved for each machine become active simultaneously with the origin shifting, that is, every

time they are recalled and therefore avoiding any possible error.

Loading...

Loading...