Indoor Installation

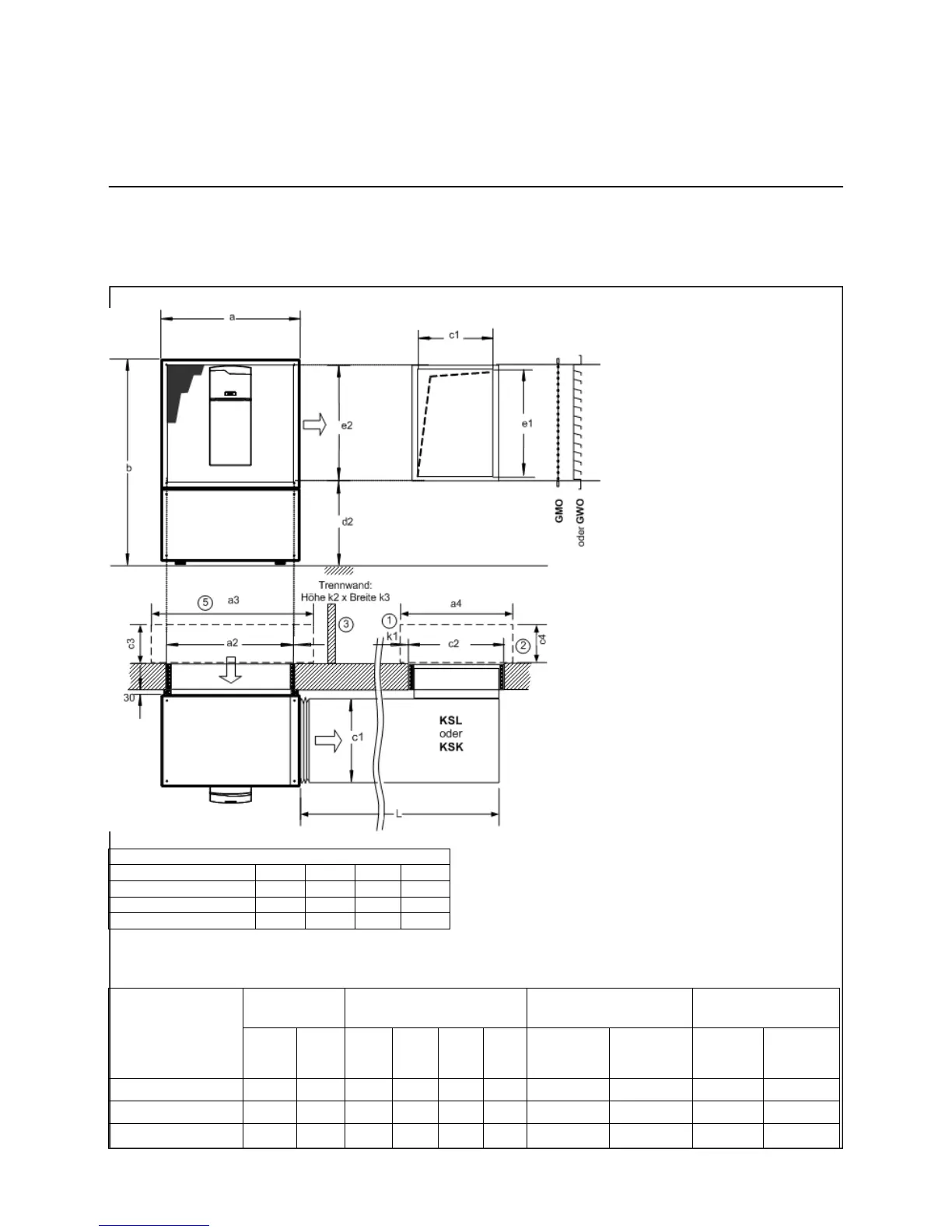

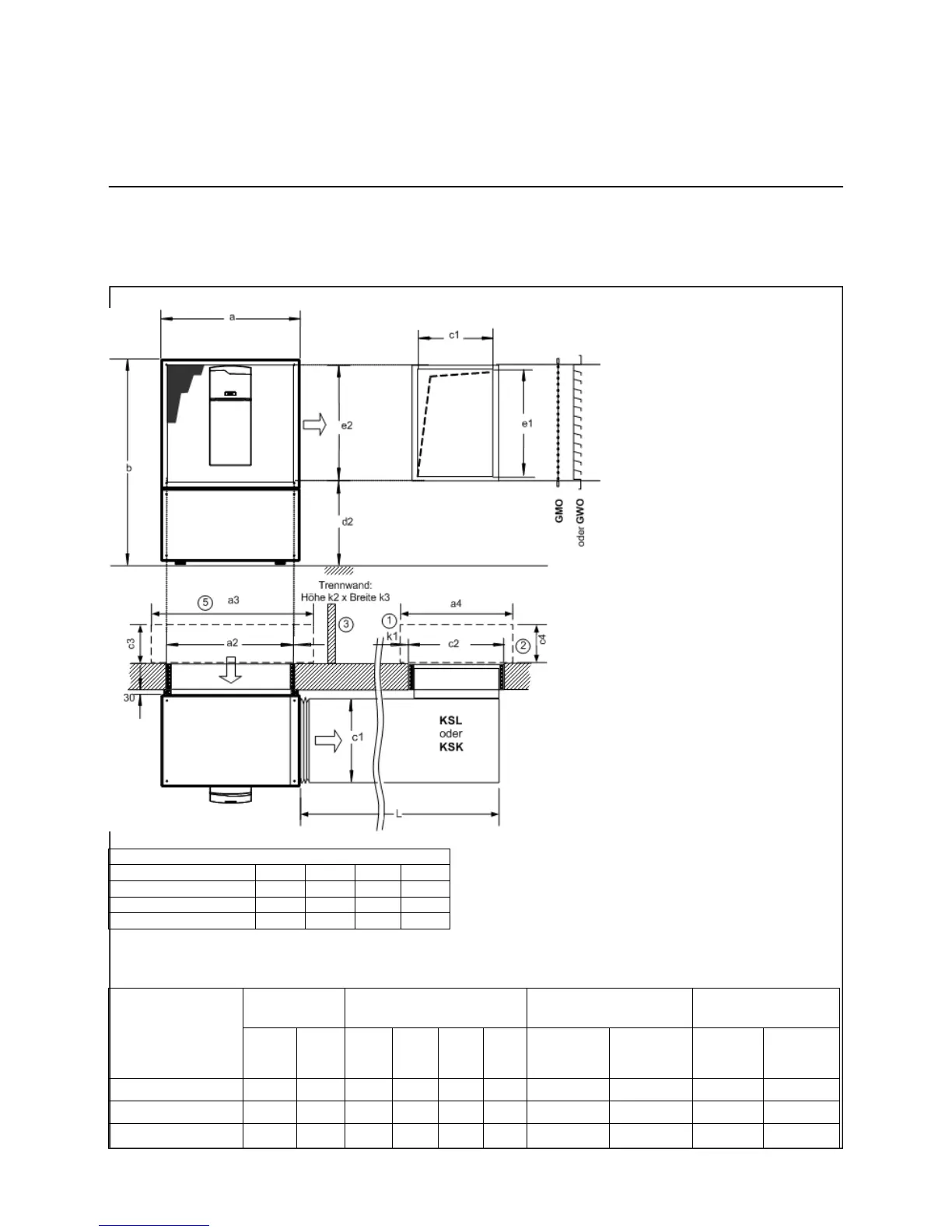

Parallel Setup with Rigid Duct

24

Required Accessories:

• AIR IN wall setup kit

• AIR OUT parallel installation with

rigid duct.

All dimensions refer to a

finished floor and completed

walls/masonry.

Light well dimension

a3 a4 c3 c4

T07C, T07 1200 800 600 600

T10C, T10 1200 1000 600 600

T12C, T12, T14, T16 1200 1000 600 600

AEROTOP T

Rigid Duct

Dimension

Cutouts without Insulation

Distance between

Cutouts

Partition Wall

e1 c1 a2 c2 d2 e2

k1 without

partition

wall

k1 with

partition

wall

Height k2 Width k3

T07C, T07 800 520 950 600 640 860 1500 630 1500 1000

T10C, T10 850 620 1050 700 640 910 1500 630 1500 1000

T12C, T12, T14, T16 950 620 1150 700 640 1010 1800 630 1700 1200

Light well

Light well

1) The compliance with acoustic

limit values must be clarified by

customer.

2) Necessary outside insulation by

customer, minimal clearance of

light well must not be gone below.

• Attach flex sleeve (A) to inside

frame of unit.

• Attach sealing tape to sheet metal

duct on the side that is attached

to the sleeve.

• Insert the sheet metal duct into

the cutout. The sheet metal duct

may not touch the wall in the cutout

at any side. This can be achieved

by placing a piece of insulation into

the center of the cutout.

• Use the enclosed screws to affix

sheet metal duct to the sleeve.

Attach the section clips (included

in installation kit) along all sides

between sheet metal duct and

sleeve. This ensures a tight

connection.

• Use insulating foam in between

the gaps of the cutout and the

sheet metal duct from the outside

of the cutout. An opening in the

sheet metal duct makes it possible

to insert the nozzle of the spray

can. Completely fill the area

between duct and cutout with foam.

• Mount air intake cover grating

on exterior wall. Select either a

mesh, protective grating, or a

sound-dampening protective

3) Possible air short-circuit to be

prevented by customer; for the

short duct (KSK) it is necessary

to apply a partition wall.

5) Noise level of AIR OUT and AIR IN

must be considered separately

Loading...

Loading...