8

Calibration of temperature sensor

NOTE! In case of replacement of effect- or display PCB,

the food temperature sensor or the heating element tem-

perature sensor, temerature values for food and heating

elemet have to be calibrated as follows:

1. Fill up the boiling pan with appr. 10 cm water.

· Press Menu forwards and Menu back simul-

taneously for 5 seconds.

· Digit the code 1122 by pressing Increase value or

Decrease value

for digits, and Menu forwards

or Menu back for the position.

· Confirm by pressing Start .

SAFETY TEST MODE

· Select SERVICE MODE, pressing Decrease value

and press Menu forwards twice.

SERVICE

JACKET TEMP XX°C

CALIBRATED X°C

2. Press Decrease value and adjust the heating ele-

ment temperature sensor at -8°C.

3. Press Menu back .

SERVICE

JACKET TEMP XX°C

CALIBRATED X°C

· Press Decrease value and adjust the food tempe-

rature sensor at -3°C.

4. Press Start .

· Stir the water inside the pan with a wooden ladle.

· Boiling process starts. When the water inside the pan

is boiling, the display shall indicate 100°C. Calibrate

the value by pressing Increase value or Decrease

value max. ±8°C.

· Press Stop .

· Press Menu forwards once and Press Start .

· The boiling pan`s manometer have to show appr. 100-

110 kPa (1,0-1,1 bar) when the display indicates 121°C.

Calibrate the value by pressing Increase value or

Decrease value max ±8°C.

· Press Stop .

· End the process by switching off the power, pressing

ON/OFF .

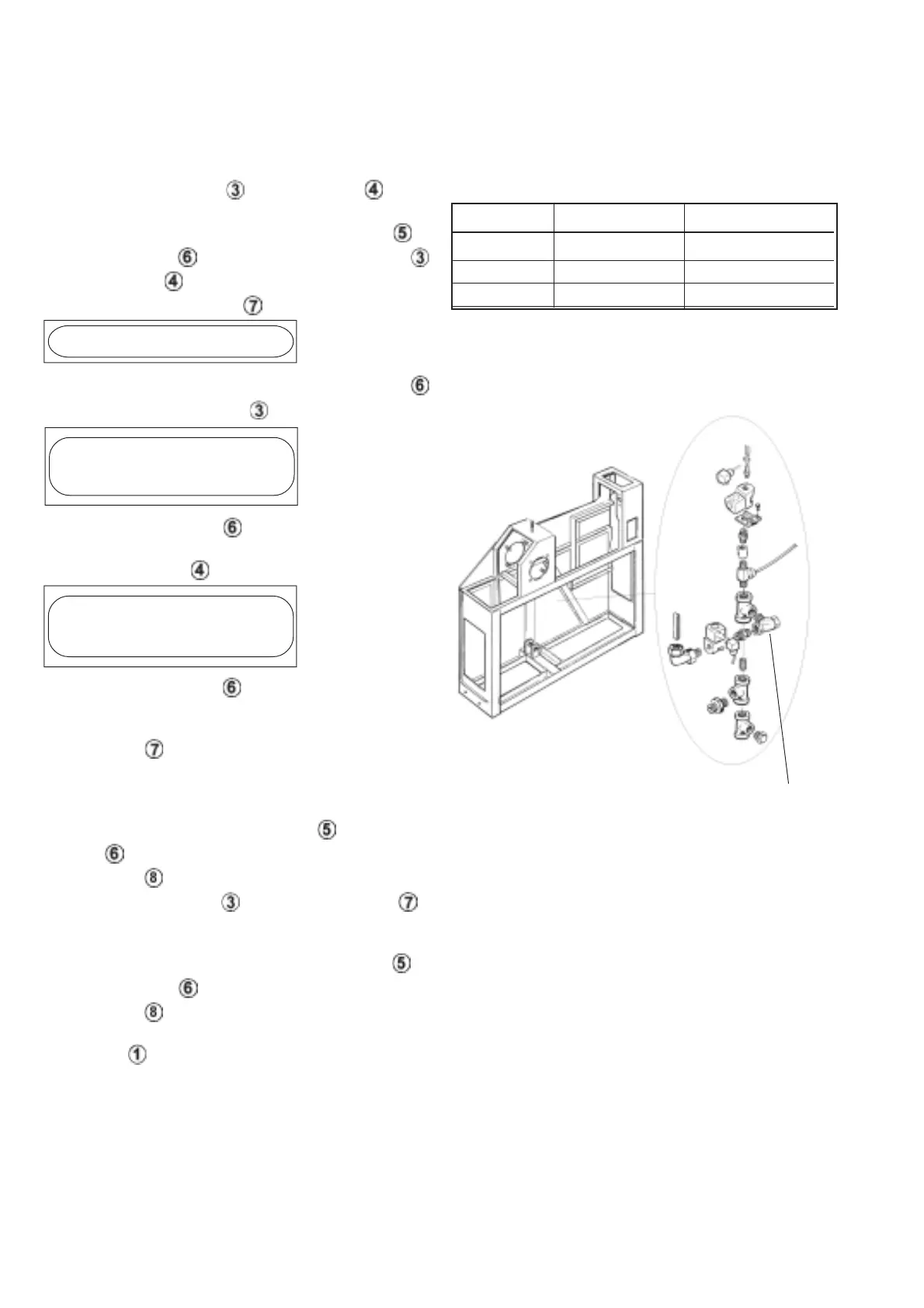

Adjustment of the jacket cooling water

1. Start the automatic cooling program, vait until a

uniform flow of water running out of both pipes.

2. Put a bucket under båth pipes and fill under 20

seconds.

3. messure the water and confer with the tabe be-

low:

Size(L) Flow (l/min.) Flow (l/20 sec.)

50-100 10 3,3

150 11 3,7

200-300 12 4

Adjust with radiator filler neck.

radiator filler neck

Loading...

Loading...