RGF 300

12/53

After the motor characteristics have been checked, the following should be defined in order to identify the

type of operating mode and application.

1.3.1 Operating mode

The

rgf

controls allow two different types of operation depending on which type of input is available:

•

operation as

REGULATOR

(also called MASTER)

the phase cutting regulators is directly connected to one or more sensors; the phase cutting is a function of

the values selected for:

#"

Set-Point P3

(trimmer

or centesimal switch)

#"

Proportional band P2

(trimmer)

•

operation as

POWER UNIT

(also called SLAVE)

In this case, the

rgf

is set up to be controlled by an external Master regulator which decides the phase cutting

of the voltage by sending the control signal to the slave.

The incoming control signal to the

rgf300

regulators can be:

For a

MASTER (mA – Vdc)

Active sensors with control in current (

mA

) or voltage (

Vdc

)

For a

MASTER (ohm)

NTC

sensors with control in

°C/ohm ( 10 kohm @ 25 °C )

For a

SLAVE (mA – Vdc)

Control signals in current (

mA

) or voltage (

Vdc

)

1.3.2 Application

It is generally possible to connect one or two sensors/control signals to all ‘

MASTER’

and

‘SLAVE’

models; with two (

2

) sensors-signals connected, the regulator automatically selects the greater or lesser

signal.

In the case of active sensors, this can be directly powered (

24Vdc / max. 40 mA

).

The principal applications are for measuring pressure (

bar

), temperature (

°C

), humidity (

%RH

), delivery

(

cu.m/h

), superpressure (

mm.

), static pressure (

Pa

), supertemperature (

destratification

) etc. in plants and

machines.

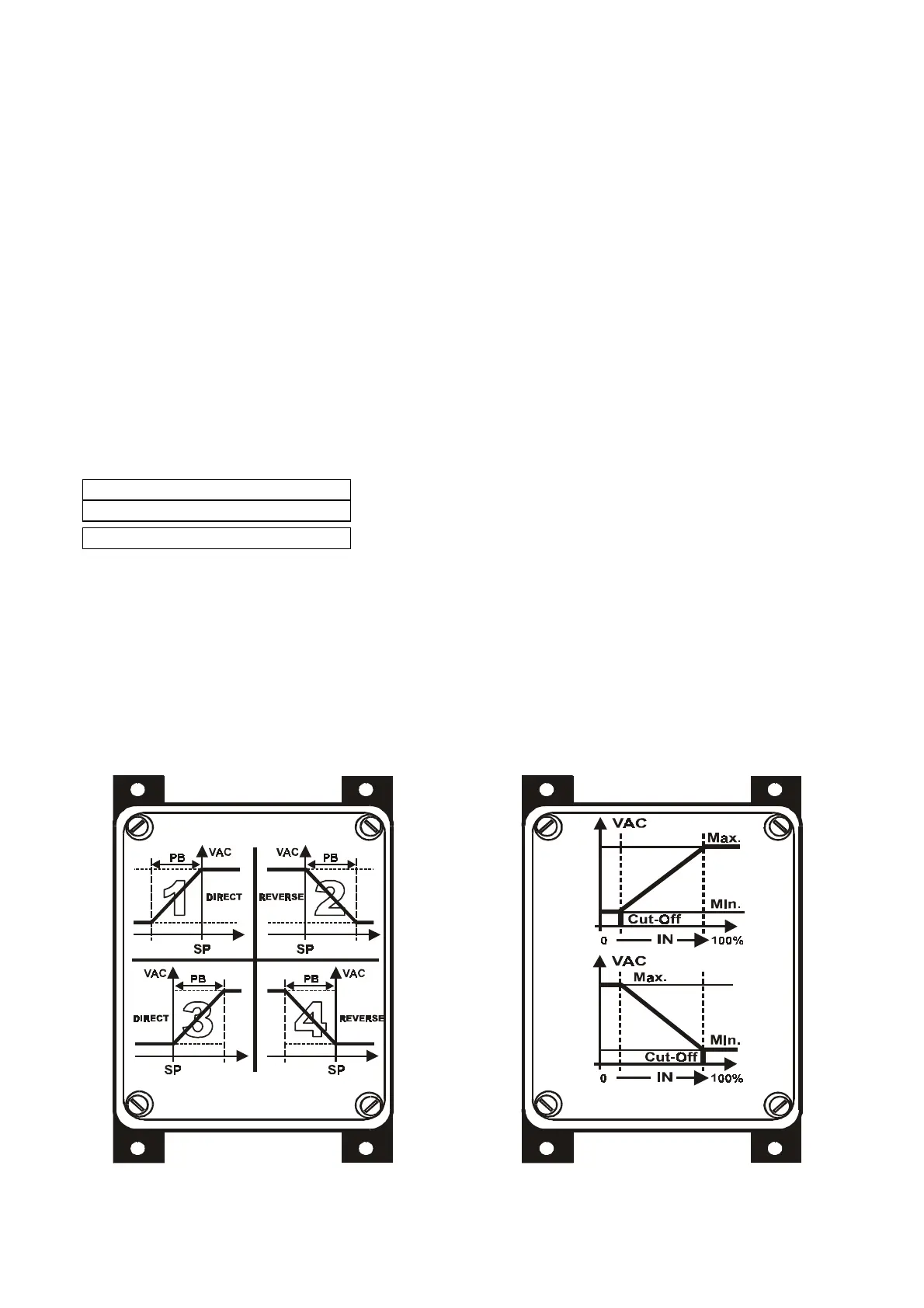

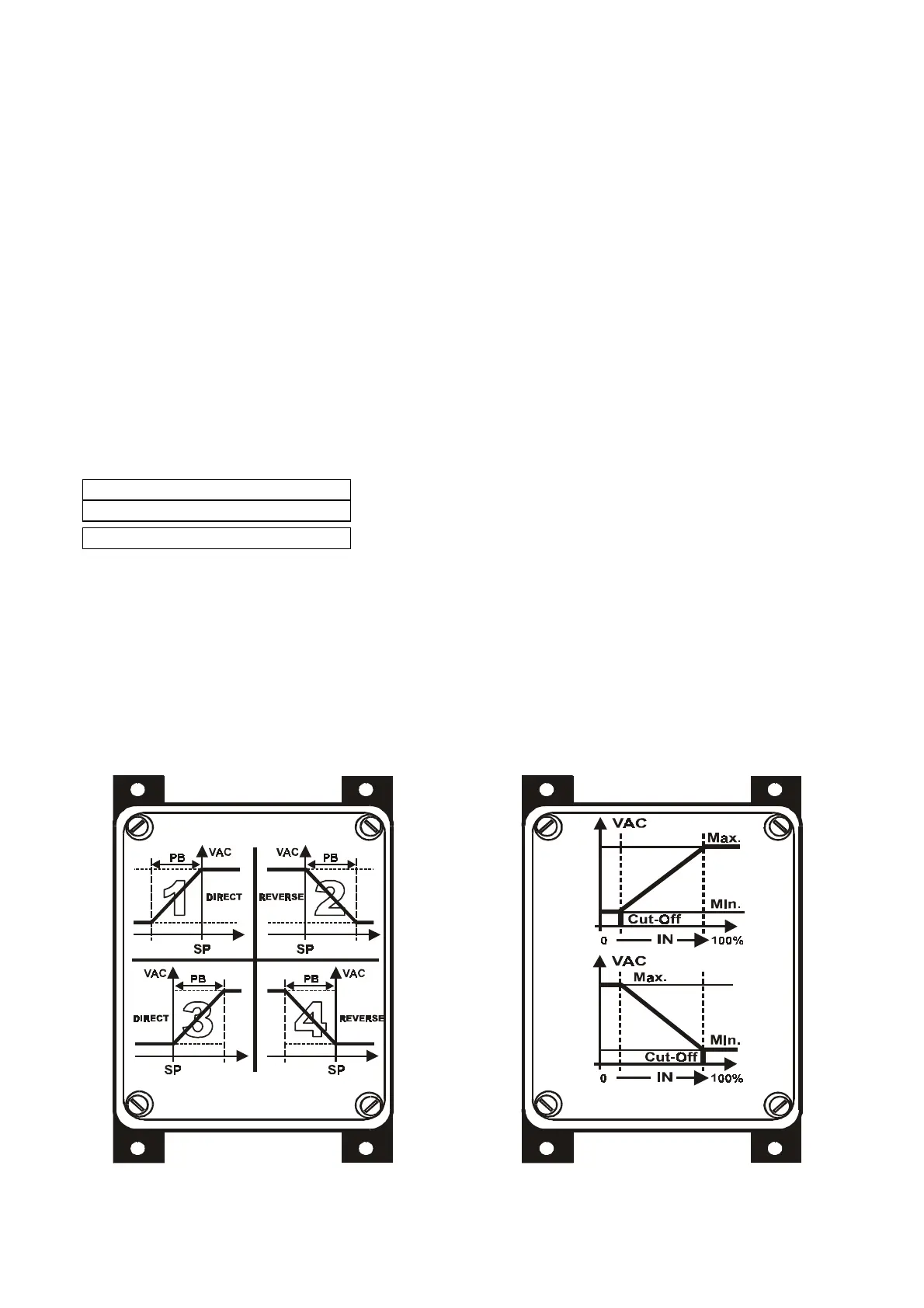

fig. 7

MASTER SLAVE

Loading...

Loading...