RGF 300

50/53

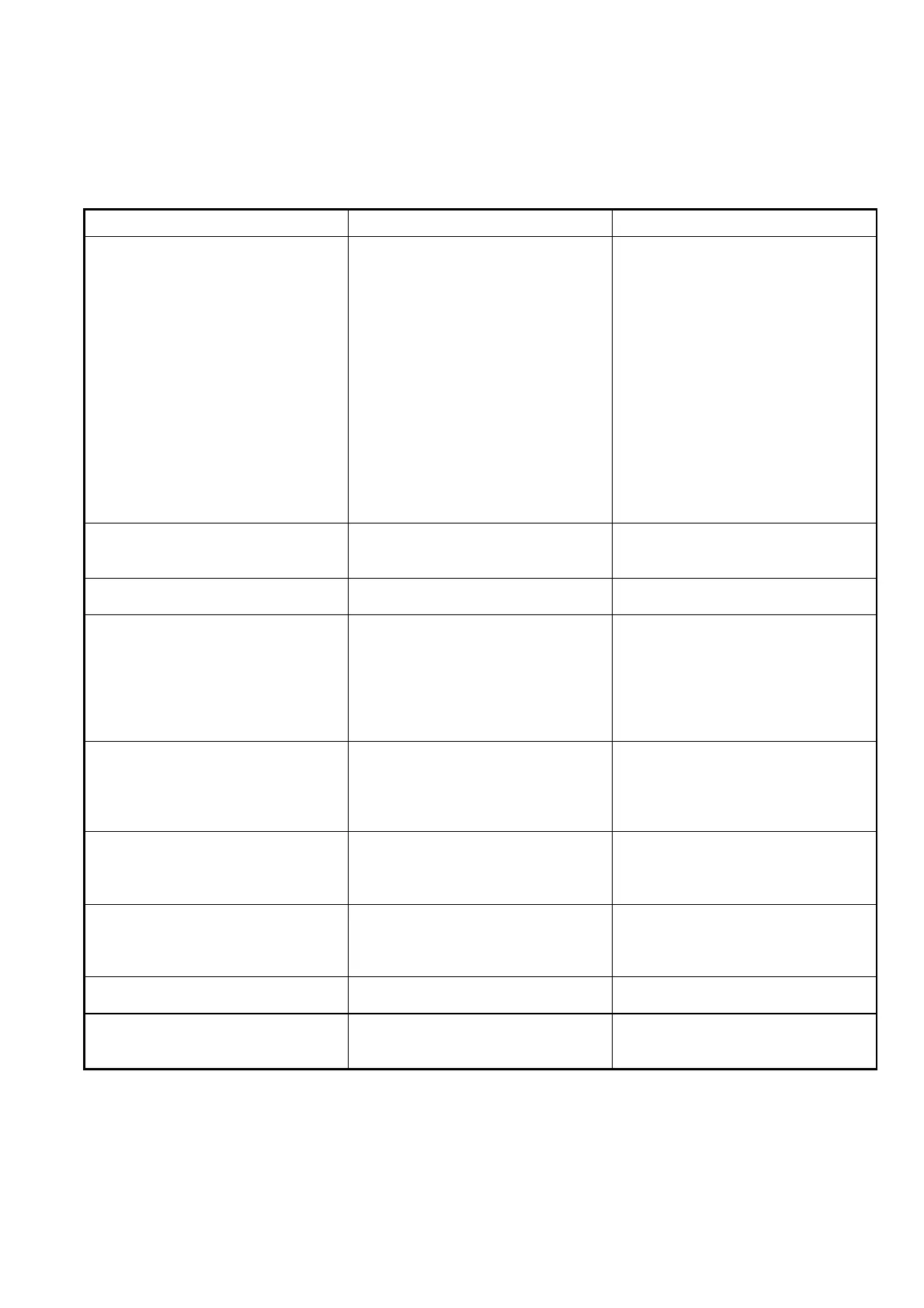

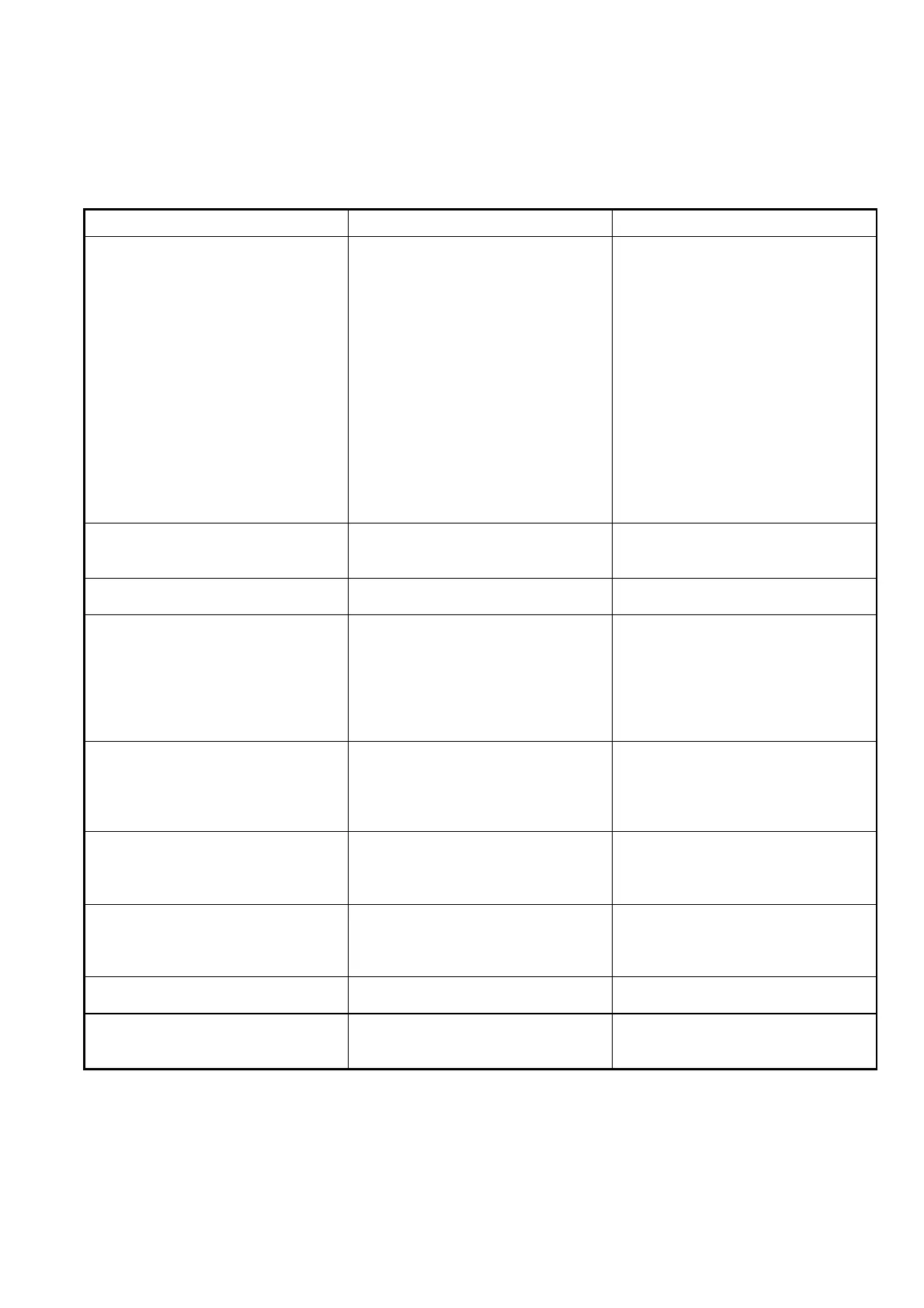

7.0 TROUBLE SHOOTING

Some of the problems which may occur during or after unit commissioning are listed below with their

possible solutions.

Problem

Cause Solution

Unit supplied but load does not activate.

C1

. Absence of one or two phases (

Led

AC LINE

on).

C2

. The load is not connected.

C3

. No control signal.

C4

. Incorrect operating mode (

direct,

reverse

) and

Set - points

not adequate

for signal control.

C5

. Maximum voltage supplied to lower

load at minimum starting voltage.

C6

. Remote

STOP

(

ON-OFF

) (

MB

4,

5

contacts closed).

S1

. Check supply connections and input

phases.

S2

. Check there are no electrical

interruptions between regulator and

load.

S3

. Check sensors for correct operation

(return voltage) and connections to

terminal board

MA

.

S4

. Check

P3

trimmer calibration and

positions of jumpers

J8/J9

,

J2/J3,

J10/J11/J12.

S5

. Check

P4

trimmer calibration.

S6

. Check

STOPS 4, 5

control contact

on

MB

terminal board.

Tension can be read on outlet terminal

heads to load (circa

370 VAC

) but

motor does not start.

C1

. Load not connected to regulator

terminals.

S1

. Check electromagnetic switch or

motor / regulator connection sectioner.

S2

. Check the motor heat protection.

Cutting regulators supplies voltage to

the load but load does not activate.

C1

. Minimum voltage supplied to load

is lower than needed for starting.

S1

. Check

P6

trimmer calibration.

Protection fuses burn out.

C1

. Regulator undersized for load used.

C2

. Interference on supply lines.

C3

.

By-pass

configuration with short

circuited phases.

S1

. Check powers involved as well as

starting and operating currents.

S2

. Check the supply line and if

necessary install mains or 'surge' filters

upstream of the cutting regulators.

S3

. Check input and output phase

correspondence.

After correctly operating for a certain

time, cutting regulators supplies the

maximum voltage load regardless of

control signal.

C1

. Lack of ventilation and/or high

working temperature in the unit.

C2

. Detection transducer faulty or short-

circuited.

S1

. Check the unit is mounted

vertically; check the room temperature

where the unit is installed.

S2

. Check input control voltage (

MA

terminal board).

Unit regulates load in

ON - OFF

operation.

C1

. Proportional band too "narrow"

with respect to system response.

C2

.

CUT-OFF

too high (

80%

).

S1

. Increase the proportional band value

with trimmer

P2

.

S2

. Decrease value of

P6.

Unit has suspended regulation and Led

TK ALARM

is on.

C1

. External safety device has

intervened (contact

MB 6,7

).

S1

. Check unit reset type (see position

of jumper

J13

).

S2

.Check activation of the safety

device and the cause of the intervention.

Unit has suspended regulation and Led

AC LINE ALARM

is on.

C1

. A fuse has burnt out or one of

supply phases is absent.

S1

. Replace supply line fuse and check

beginning of line upstream.

Output voltage constant even with

control signal activated and

MANUAL

(Heat-Pump mode)

Led is on.

C1

. The

MAN

contact (heat-pump) is

closed.

S1

. Select correct operating mode (

NO

contact) by activating contacts

2,3

of

terminal board

MB

.

Table 7

Loading...

Loading...