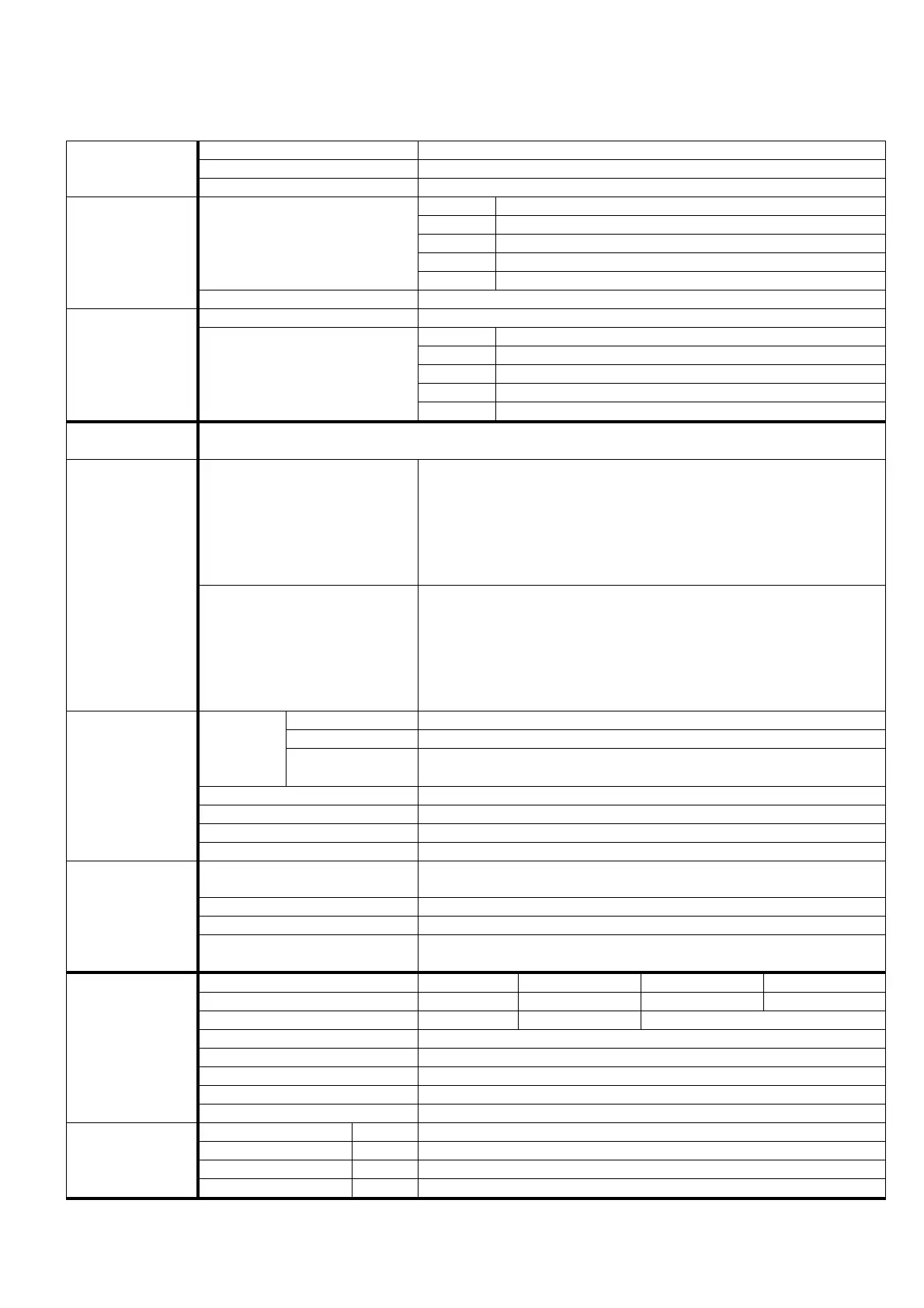

RGF 300

14/53

1.5 rgf

300 TECHNICAL C

HARACTERISTICS

Voltage

420V

AC

+/- 10 %

three-phase (

230V

AC

and

500V

AC

on request)

Frequency

50 Hz

(

60 Hz

)

S

UPPLY

Overvoltage protection for installation Category

II

(

4 KV

)

RGF 312

12 A

up to

50°C

environment, over decrease by

0.6 A/°C

RGF 320

20 A

up to

50°C

environment, over decrease by

1.0 A/°C

RGF 325

25 A

up to

50°C

environment, over decrease by

1.2 A/°C

RGF 340

40 A

up to

50°C

environment, over decrease by

1.8 A/°C

Rated

RGF 360

60 A

up to

50°C

environment, over decrease by

2.5 A/°C

C

URRENT

Overload

200%

of the rated current (max.

10”

every

3’

)

Control circuits

10VA

RGF 312 72 W @ 12A

RGF 320 120 W @ 20A

RGF 325 150 W @ 20A

RGF 340 240 W @ 40A

P

OWER

Thermally dissipated

RGF 360 360 W @ 60A

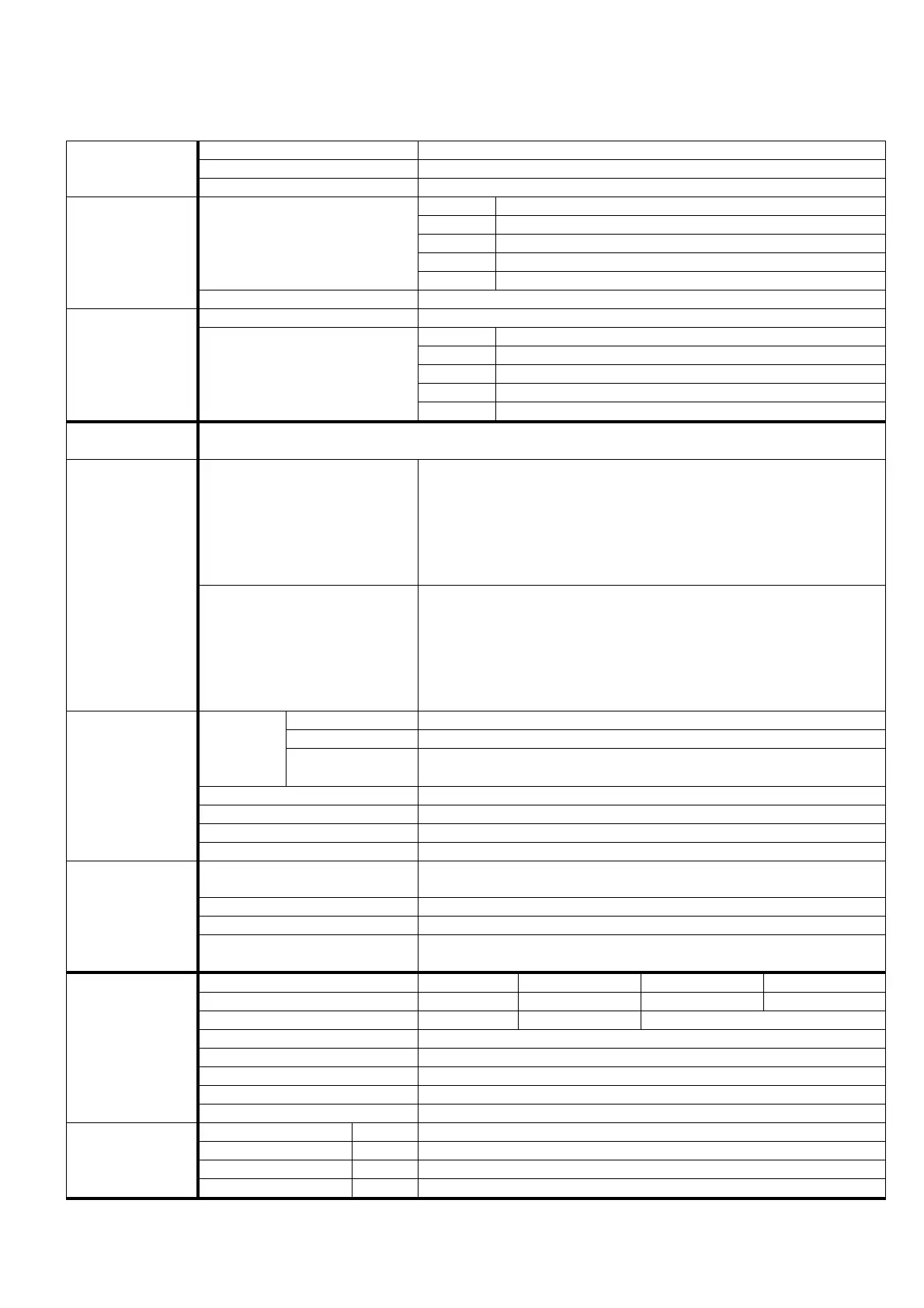

O

PERATING

PRINCIPLE

Totally controlled three-phase cutting, with compensation for inductive loads and motors, without need for

connection to NEUTRAL

POWER unit

(Vers.

M , V

)

The output voltage depends on the control signal prevailing between the

two available at the inputs, which is chosen by means of the pre-

established mode, according to the specific appliance regulating curve.

The action can be :

DIRECT

, with the output increasing as the input increases, or

REVERSE

,

with the output decreasing as the input increases.

Standard Config.

: output increasing as the controlled variable increases

O

PERATING

CHARACTERISTIC

Regulator

(Vers.

M , V , X , Y

)

The output voltage changes to keep set to the target point, selected with

the Set-Point, the quantity measured by the transducer prevailing

between the two available at the inputs, which is chosen by means of the

pre-established mode (greater or lesser in value).

The action mode, either

direct

or

reverse,

is chosen in consideration of

the controlled quantity, transducer characteristic and load action.

Standard

: output increasing as the controlled variable increases

Vers.

M

Two

0-20 mA, Ri = 100 hom

analog inputs, priority to the greater std.

Vers.

V

Two

0-10 Vdc, Ri = 10 khom

analog inputs, priority to the greater std.

Control

Vers.

X, Y

Two

kohm

analog inputs for the

NTC

sensors supplied (

10KΩ

ΩΩ

Ω @

25°C)

, priority to the hottest sensor std.

Heat protection

O

N

/O

FF

input, motor protection NC thermal contact

Start/Stop

O

N

/O

FF

input

:

Off Vin=0 =

Start /

O

N

(

V

IN

=24V

) : Stop

Automatic/Manual

O

N

/O

FF

input

:

Off (Vin=0) =

Automatic /

O

N

(

V

IN

=24V

)=Manual

I

NPUT

SIGNALS

Set-Point 1 / Set-Point 2

O

N

/O

FF

input for Set-point 1/2 commutation (Only with

PB1064

)

Transducer supply

Two

+22Vdc (-10% / +20%) 40 mA

non-stabilised outputs, protected

from short circuit

Potentiometer supply Two

+10Vdc / 5 mA

stabilized outputs

Auxiliary control

0-10V / 1 mA

analog output for cascade control of other

SLAVE

units

O

UTPUT SIGNALS

RL1

service relay

NO/NC

relay contact, free from potential, for separate or joint signalling

of :

alarm signals absent / start enabling / voltage supply

Version & Input M: 0-20 mA V: 0-10 Vdc X: +10/+60°C Y: -20/+20°C

Target value

0 ... 20 mA 0 … 10 Vdc +10 ... +60 °C -20 ... +20 °C

Proportional range

0.4 … 4 mA 0.3 … 3.5 Vdc 3 … 30 °C

Minimum limit / Cut-Off Adjustable from

0%

to

100%

Maximum limit Adjustable from

100%

to

0%

Acceleration ramp Adjustable from

1”

to

10”

Direct/Reverse presetting Action mode of input prevailing over output :

Direct or Reverse

A

DJUSTMENTS

AND

P

RESETTINGS

Prevailing input presetting Selection mode for prevailing input :

greater

/

smaller

AC L

INE

A

LARM

ON Red

Signals locked state due to absence of one supply phase

T.K. A

LARM

ON Red

Signals locked state due to motor thermal protection

NC

contact opening

RL1 ON Green

Signals

RL1

service relay energised state

LED

SIGNALLING

M

ANUAL

M

ODE

ON Yellow

Signals “

M

ANUAL

” operation state at fixed speed

Loading...

Loading...