41

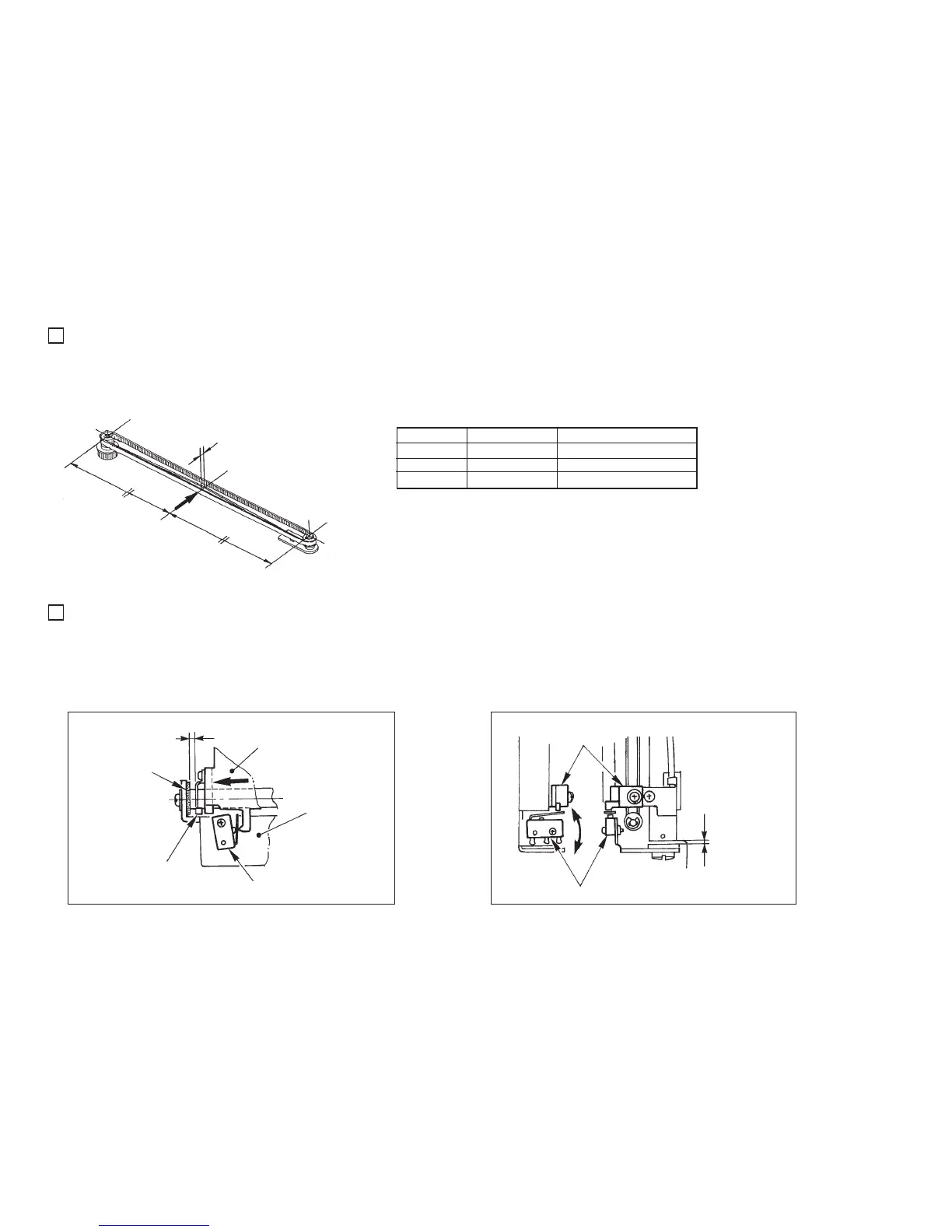

2 Adjusting the belt

When the STM or the like has been replaced, it is necessary to adjust the belt tension. Perform the adjustment as shown in the figure below.

1 Remove the belt holder. (One screw)

2 For the proper belt tension, adjust the respective pulleys (asm.) so as to obtain the deflection described in the table below when a load of 0.98 N (100 g) is applied to the

midway of the belt, and tighten screws (two screws).

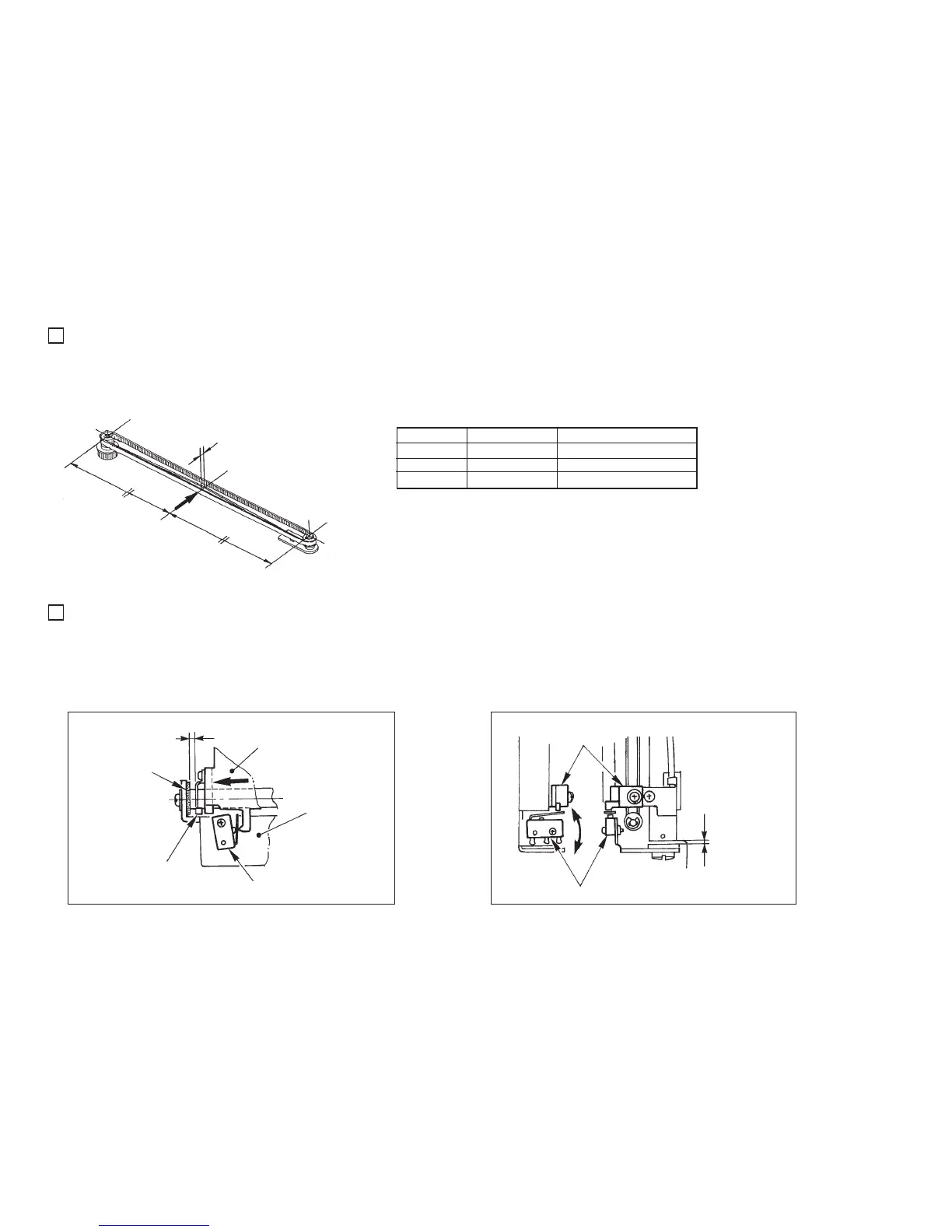

3 Adjusting the origin

[X origin]

Insert a gauge of 1 mm between the X drive felt B and the X drive shaft holder

presser, and adjust so that the X detecting switch (asm.) is turned ON when the X

drive plate (asm.) is shifted in the direction of the origin.

Clearance gauge of 1mm

X drive shaft

felt B

X detecting switch (asm.)

X drive drive shaft

holder presser

X drive plate (asm.)

Main frame (asm.)

A m/m

0.98 N

(100g)

Belt

Pulley (asm.)

Y belt

presser

Clearance gauge

of 1 mm

• If the belt is excessively tensed, the STM will step out.

• If the belt is insufficiently tensed, the belt will move lightly but skipping will occur.

• Before starting to adjust the belt, check the frame holder (asm.) and Y drive shaft, and X drive plate(asm.)

and X drive shaft. (Standard :The drive shafts need no lubrication. They automatically drop (slide)

when they are inclined by 45fl.)

Y detecting switch (asm.)

[Y origin]

Insert a gauge of 1 mm between the frame holder (asm.) and the Y drive shaft felt A,

and adjust so that the Y detecting switch is turned ON when the frame holder (asm.)

is shifted in the direction of the origin.

Components to be adjusted

X pulley (asm.)

Y pulley (asm.)

Y intermediate pulley (asm.)

X drive belt

Y drive belt

Y drive belt

A (deflection) mm

3.5 to 4.5

3.5 to 4.5

2.5 to 3.5

Loading...

Loading...