2002 by ELTRA GmbH Germany – January 2002 – Service Manual OH 900 / ON 900 / ONH 2000

1.20-1

1.20 The upper electrode gets dark:

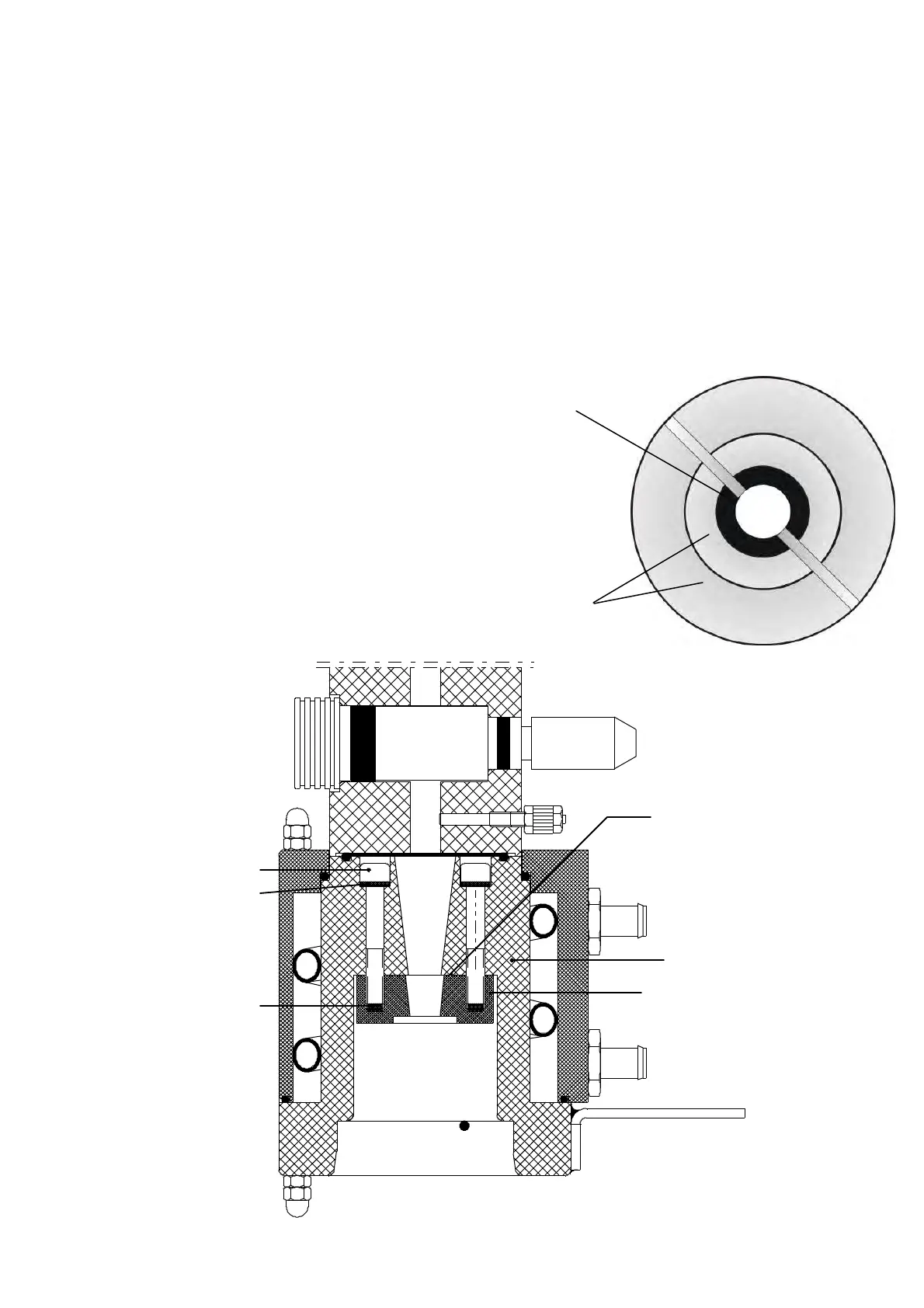

It is normal when the surface of the upper electrode insert that gets in contact with the

crucible, darkens. This dark surface builds a ring ( 1 ) of a few milimeters width around the

hole of the electrode. All the rest of the electrode surface keeps the original shiny surface

of the nickel coating, so that after cleaning from the graphite dust it looks like a new

electrode, except the a.m. ring that touches the crucible.

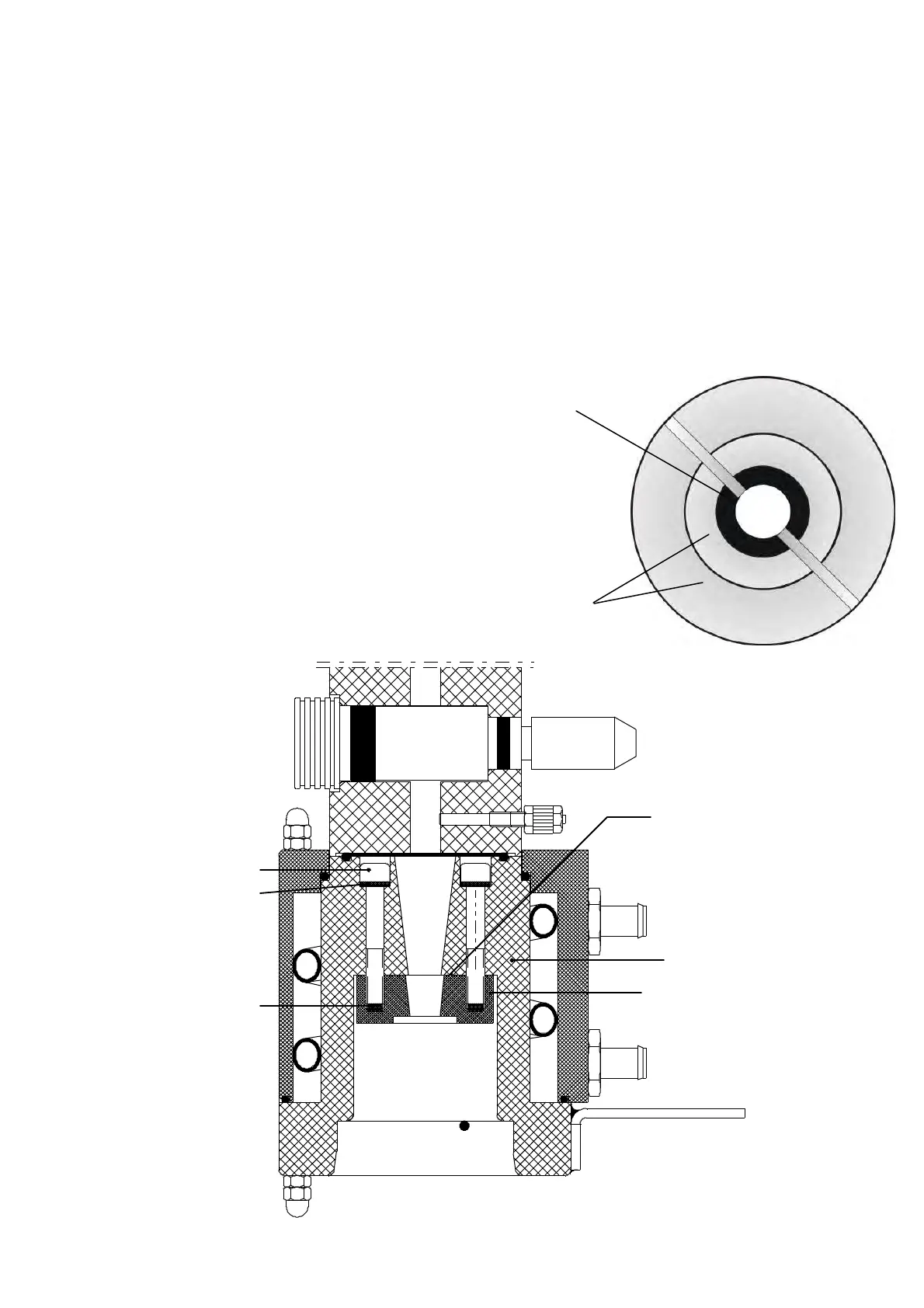

But if the complete surface of the electrode gets dark, this means that the whole electrode

has been overheated.

If the power settings are still the same as they used to be before when the electrodes

didn`t overheat, or if the settings are not higher than advised in the applications of the

operation manual, the reason of overheating must be a bad thermal ( and bad electrical )

contact to the upper furnace block, caused by:

Dark ring ( 1 )

a) not properly fixed screws ( 2 ),

b) grains or any other parts between

the electrode ( 3 ) and the upper

furnace block ( 4 ), or

c) the spring lock washers ( 5 ) are missing or

d) there is too much graphite powder ( 6 ) in the

thread of the electrode underneath the screws.

The graphite powder is used to fill the volume

underneath the lower end of the screws ( 2 )

Shiny

eliminating any air enclosures.

surface

12-0

Sample

drop

Electrode screws

fix properly (2)

Spring lock

washers (5)

Graphite

powder (6)

Make sure that

there are not

any grains or any

other material

between the

electrod and the

upper furnace block.

Upper electrode

insert (3)

Upper furnace

block (4)

Loading...

Loading...