POWERJET MANUAL

8f749dd9-8865-44fd-baed-1b68166d2198file.doc

POWERJET OWNERS INSTALL & OPERATE MANUAL

The following info does NOT apply to units equipped with a Heavy Duty SEALLESS Pump & Motor (5HP or 2HP) assembly !

INSTALLATION OF STANDARD MECHANICAL PUMP SEAL (Grainger p/n 1R303)

Please Note:

ONE- Extra / Spare PUMP SEAL (Grainger part no.1R303) is included and shipped with EMC POWERJET units equipped with a

standard 120GPM Pump & 1½HP Motor assembly. It is packed in the plastic bag along with this Manual (a small box, 1½”x1½”x1½”).

FOR LUBRICATION: - USE WATER SOLUTION OF SOAP OR DETERGENT.

- DO NOT OVER LUBRICATE.

- NEVER USE PETROLEUM OILS. (e.g. Baby Oil, Mineral Oil, etc.)(Seal manufacturer’s recommendation)

- But, any Lubrication is better than none.

CAUTION: This seal is a precision product and should be handled accordingly.

Be especially careful of the lapped sealing face of the rotary washer and stationary seat.

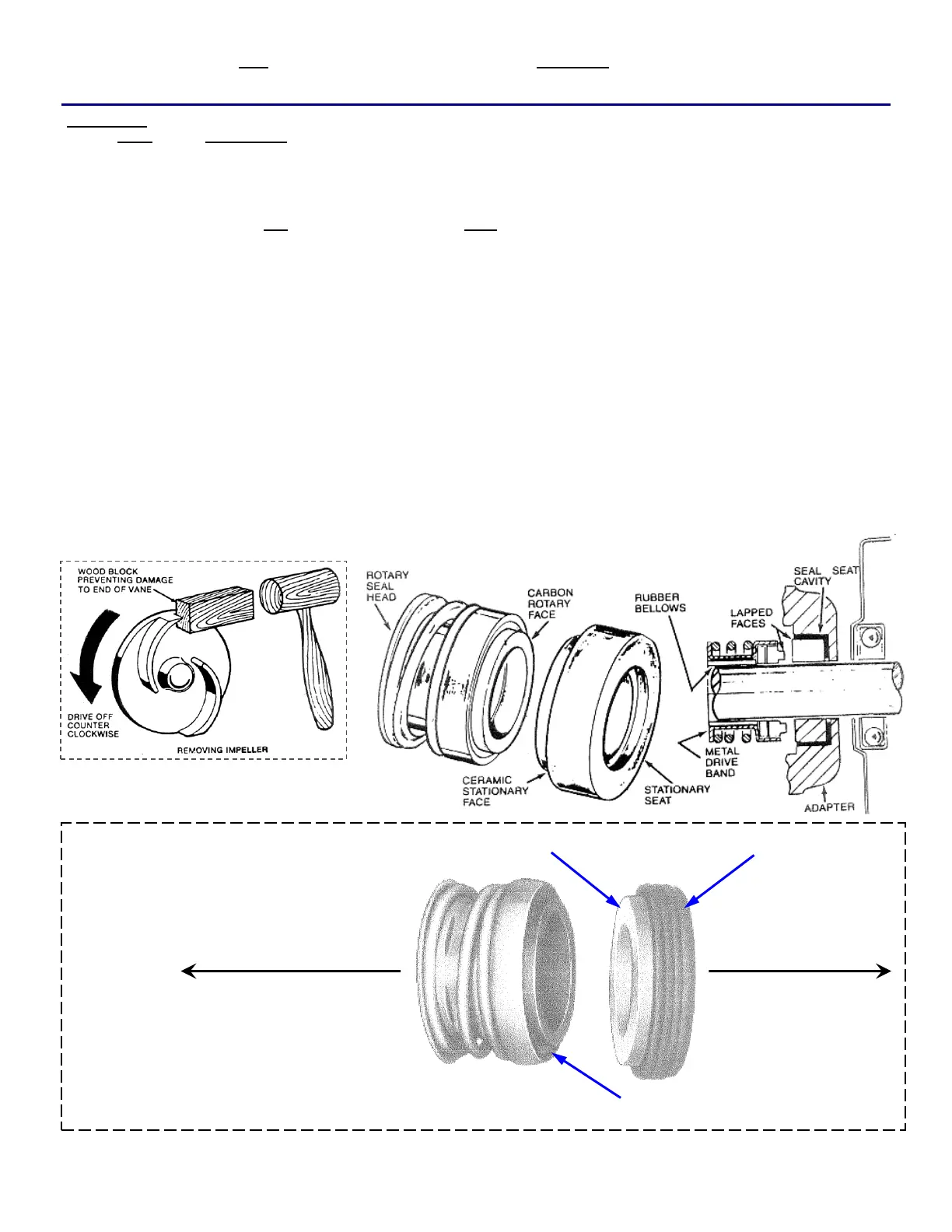

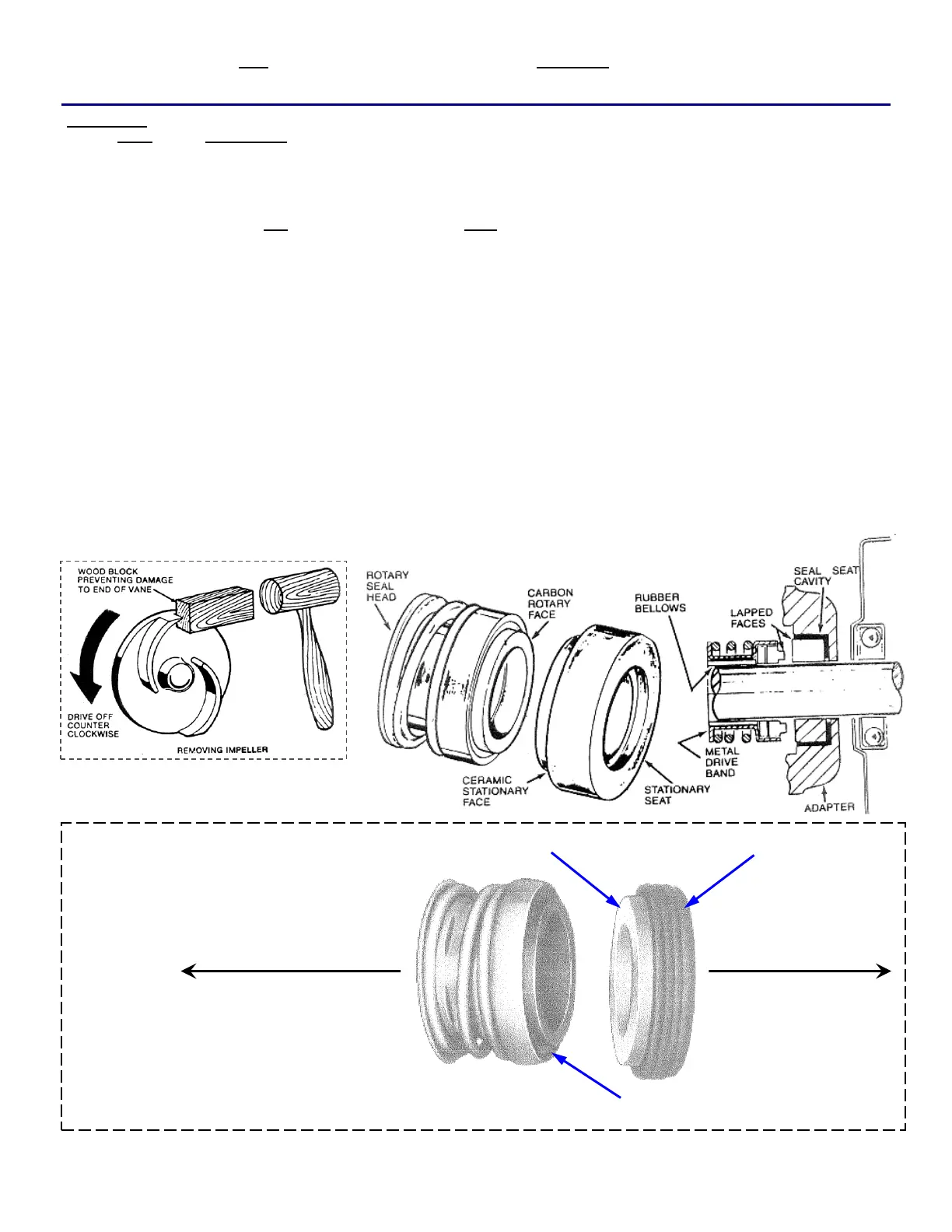

LAPPED RUNNING FACES:

The lapped running face of the rotary seal head and stationary seat must be treated with care. KEEP CLEAN, DO NOT SCRATCH.

Use a clean, soft cloth during installation. Protect the faces. Install both the seat and rotary square to the shaft.

Check stationary seat installation from behind seat cavity for squareness.

STATIONARY SEAT:

Clean seal cavity in pump adapter. Lubricate rubber “O” –Ring or rubber cup and press seat firmly and squarely into seal cavity with

lapped face up. Must be pushed square and all the way into the cavity. Be careful not to scratch lapped face. Use a clean, soft cloth to

protect seal face.

ROTARY SEAL HEAD

Clean, Polish and Lubricate shaft or shaft sleeve. Check lapped faces on stationary seat and rotary seal head. Be certain no dirt is on

either face. Lubricate rubber bellows. Slide rotary seal head on shaft. Press on metal drive band until the two faces touch. Install

impeller. This will compress the spring to proper height. This compression assures the proper pressure on the lapped running faces.

CAUTION

Never run the lapped faces dry. The liquid being pumped insures proper lubrication.

In some cases a short running period is required to clear up slight leakage.

Item #: 1R303

Desc: 5/8” PUMP SHAFT SEAL

Add’l Info.: TYPE 16

Page: 2724

From Grainger Electronic Catalog No. 387 Copyright (c) 1996, W.W. Grainger, Inc., All Rights Reserved

Loading...

Loading...