FloBoss 107 Instruction Manual

Revised June-2017 Inputs and Outputs 4-7

Note: Once you remove a module, always be sure to replace its cover.

This protects the module slot from dust and prevents damage to

the cover’s locking mechanism.

4.4 Wiring a Module

I/O wiring requirements are site and application dependent. Local, state,

or NEC requirements determine the I/O wiring installation methods.

Direct burial cable, conduit and cable, or overhead cables are options for

I/O wiring installations.

All I/O modules, the CPU I/O assembly, and RTD inputs have terminal

blocks for convenient wiring and servicing. The terminal blocks

accommodate size 16 to 24 AWG.

Failure to exercise proper electrostatic discharge precautions, such as

wearing a grounded wrist strap may reset the processor or damage

electronic components, resulting in interrupted operations.

To connect the wire to the removable block compression terminals:

1. Strip ¼ inch of insulation from the wire.

2. Insert the bare end into the clamp beneath the termination screw.

3. Tighten the screw, taking care not to over-torque it.

Expose a minimum of bare wire to prevent short circuits. Allow some

slack when making connections to prevent strain.

Note: Twisted-pair cable is recommended for I/O signal wiring.

4.5 Selecting the Type of I/O

Configure all AO/DO points in ROCLINK before connecting any wiring.

Failure to do so may result in physical damage to the I/O board.

Using ROCLINK 800, you select the type of input or output.

1. Log on to the FB107 using ROCLINK 800.

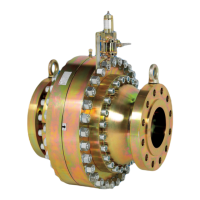

Note: ROCLINK 800 provides an enhanced graphical user interface

(GUI) for the FB107. This interface displays an image of the

FB107 above a tabbed screen (see Figures 4-4 and 4-5). You

select the FB107 module and then use the tabbed screen to

configure the components.

2. Click the I/O module. The display immediately under the FB107

image changes to reflect your selection.

Loading...

Loading...