Safety

Information

Introduction

Product

information

System

design

Mechanical

installation

Electrical

installation

Getting

started

Optimisation

Parameters

Technical

data

Component

sizing

Diagnostics

90 Unidrive SP Regen Installation Guide

www.controltechniques.com Issue Number: 2

L is the total input inductance. This is the inductance value in Pr 3.02 (at

power-up this parameter is zero). Each time the Regen drive is enabled

the total input inductance is measured and displayed in Pr 3.02. The

value given is only approximate, and will give an indication as whether

the input inductance is correct for the sinusoidal rectifier unit size. The

measured value should include the supply inductance as well as the

Regen drives input inductors, however, the supply filter capacitance,

masks the effect of the supply inductance. Therefore the value

measured is usually the Regen drive regen inductor value.

I

fs

is the peak full-scale current feedback

I

fs

= Drive rated current x √2 / 0.45 (Drive rated current [Pr 11.32])

Vfs is the maximum DC bus voltage.

Therefore:

Pr

4.13

= Kp = (L / 167

µ

s) x (Drive rated current x

√

2 / 0.45 / Vfs) x (256 / 5)

= K x L x Rated drive current

Where:

K = √2 / (0.45 x Vfs x 167µs) x (256 / 5)

This set-up will give a step response with minimum overshoot after a

step change of current reference. The approximate performance of the

current controllers will be as given below. The proportional gain can be

increased by a factor of 1.5 giving a similar increase in bandwidth,

however, this gives a step response with approximately 12.5%

overshoot.

Table 8-1 Current loop sample times

As previously detailed the current controller integral gain, Pr 4.14 is not

so critical with the recommended value being the default setting.

8.3 Voltage controller gain (Pr 3.06)

Even when the voltage controller gain is set correctly there will be a

transient change of DC bus voltage when there is a change in the load

on any motoring drive connected to the Regen drive. This can be

reduced substantially by using an analogue input for power feed forward

compensation.

The following discussion relates to a system without power feed-forward

compensation.

If the power flow from the supply is increased (i.e. more power is taken

from the supply or less power is fed back into the supply) the DC bus

voltage will fall, but the minimum level will be limited to just below the

peak rectified level of the supply provided the maximum rating of the unit

is not exceeded.

If the power flow from the supply is reduced (i.e. less power is taken from

the supply or more power is fed back into the supply) the DC bus voltage

will rise. During a rapid transient the DC bus will rise and then fall as

shown in Figure 8-3 DC Bus transient .

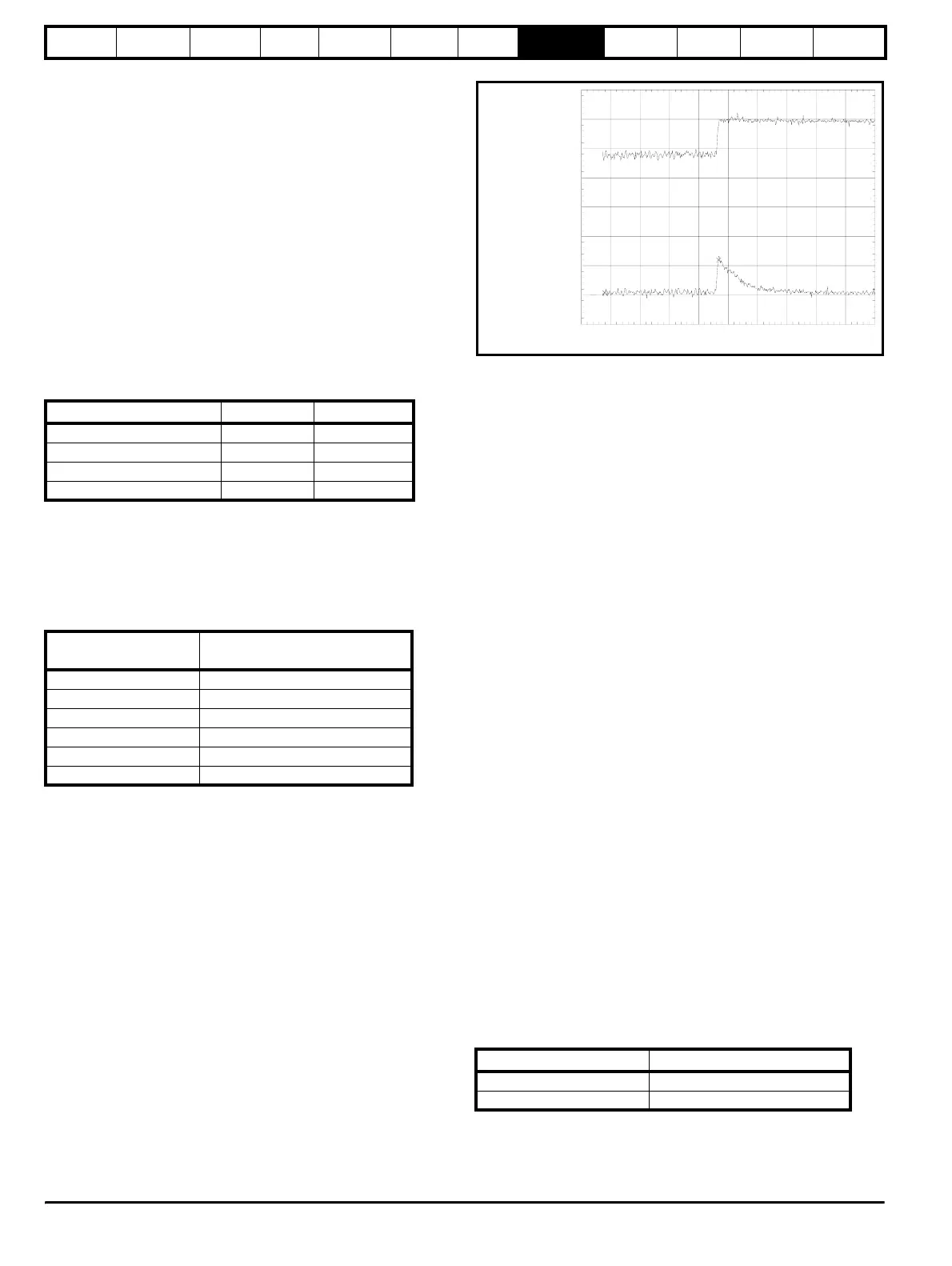

Figure 8-3 DC Bus transient

The example shown is for a very rapid load change where the torque

reference of the motor drive has been changed instantly from one value

to another.

The proportional gain of the voltage controller, Kp, Pr 3.06, defines the

voltage transient because the integral term is too slow to have an effect.

(In applications where the motor drive is operating under speed control,

the speed controller may only require a limited rate of change of torque

demand, and so the transient voltage may be less than covered in the

discussion below.)

If the DC Bus voltage set point voltage Pr 3.05, plus the transient rise

exceed the over-voltage trip level the Regen drive will trip.

When a 400V motor is operated above base speed from a drive in

closed loop vector mode, fed from the Regen drive with the same rating,

supplying a DC voltage of 700V, and an instantaneous change of torque

is demanded (i.e. -100% to +100%) the peak of the voltage transient

(∆V) is approximately 80V if the current controllers are set up correctly

and the voltage controller uses the default gain. (Operating with

maximum voltage on the motor, i.e. above base speed, gives the biggest

transient of power and hence the biggest value of (∆V. )

If the load change, drive voltage rating, motor voltage or DC Bus voltage

set point are different then ∆V is calculated from:

∆V = 80V x K

L

x K

RAT

x K

MV

x K

SP

Where:

K

L

= Load change / 200%

K

RAT

= Drive voltage rating / 400

K

MV

= Motor voltage / 400

K

SP

= 700 / DC bus voltage set point

In some applications, particularly with a high DC bus voltage set point

and low switching frequency it may be necessary to limit the rate of

change of power flow to prevent over voltage trips. A first order filter on

the torque reference of the motor drive (Pr 4.12) is the most effective

method to reduce the transient further. (A fixed limit of the rate of change

of torque demand is less effective.) Table 8-2 Rate of change gives an

approximate indication of the reduction in ∆V for different time constants.

(As already mentioned the value of ∆V given is for an instantaneous

change of torque representing the worst case. In applications where a

speed controller is used in the motor drive the transient will already

include an inherent filter).

Table 8-2 Rate of change

The transient produced is approximately proportional to the voltage

controller gain Pr 3.06. The default voltage controller gain is set to give a

value that is suitable for most applications. The gain may need to be

increased if the DC bus capacitance is high compared to two drives of

Drive voltage rating Vfs K

200V 415V 2322

400V 830V 1161

575V 990V 973

690V 1190V 809

Switching frequency

kHz

Current control sample time (T)

µs

3 167

4 125

683

8 125

12 83

16 125

Time constant Change in ∆V

20ms x 0.75

40ms x 0.5

Regen unit

DC bus voltage

Active regen

unit current

ch3: dT= 194ms dV=2.24 V

50ms/div

Loading...

Loading...