Deltapilot M FMB50/51/52/53

8 Endress+Hauser

Level measurement with

automatic density correction

(with media changing in the

tank)

Level measurement with automatic density correction is possible in conjunction with a limit switch such as

Liquiphant and a PLC. The limit switch always switches at the same level. In the switch point, the signal

processing unit determines the corrected density from the pressure of the Deltapilot M currently measured and

the known distance between Deltapilot M and the limit switch. The signal processing unit then calculates the

level from the new density and the measured pressure of the Deltapilot M.

P01-FMB5xxxx-15-xx-xx-xx-007

Level measurement with automatic density correction

1Deltapilot M

2 Liquiphant

3PLC

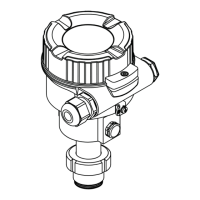

Electrical differential pressure

measurement with gauge

pressure sensors

P01-FMB5xxxx-14-xx-xx-xx-004

1 Shut-off valves

2 e.g. filter

In the example given, two Deltapilot M devices (each with a gauge pressure sensor) are interconnected. The

pressure difference can thus be measured using two independent Deltapilot M devices.

Caution!

If using intrinsically safe devices, strict compliance with the rules for interconnecting intrinsically safe circuits

as stipulated in IEC60079-14 (proof of intrinsic safety) is mandatory.

System integration The device can be fitted with a tag name and a preset bus address, see → ä 53 ff "Ordering information"

feature 895 "Identification:" version "Z1" and "Z2".

Fieldgate

FXA520

FXN 520

FXN 520

Multidrop-Connector

FXN520

Deltapilot M

➀

➁

➀

➁

Loading...

Loading...