Use and maintenance manual

MAINTENANCE - 23

E2.2 Checks on a weekly basis or per 50 hours’ operation

Maintenance interventions to be carried out weekly or after 50 hours’ operation:

- Verify the integrity of all pipelines (tightening connections, integrity of the protections or hydraulic oil leakage);

- Check the hydraulic oil leakages on the circuits of the central wheels. To restore the level, see section C3.

- Verify the integrity of all the adhesive labels;

- check the presence of the various safety pins and R pins blocking the various equipment parts;

- verify the structural integrity of all equipment parts, in particular those subject to wear like, for example, the tire wheels;

- check the fastening of nuts and screws blocking the various equipment parts;

E3 Lubrification

To insert grease into the greaser, first remove their protective caps (where there are caps), then clean them removing any traces of

dust, using the appropriate pump, and inject the grease. When the operation is finished, clean the greaser from grease excess and

then put the caps on. Use a brush to spread the grease where there are no greaser.

Only use oil type suggested by the Manufacturer (AGIP GR MU EP 2). All lubricant points on the rake are indicated by adhesive

labels, as shown at the side.

IMPORTANT

To avoid polluting, it is forbidden to disperse oil, lubricants, filtering cartridges or other toxic materials in the environment. Scrupulously comply with the current

dispositions for the disposal of liquid and solid substances.

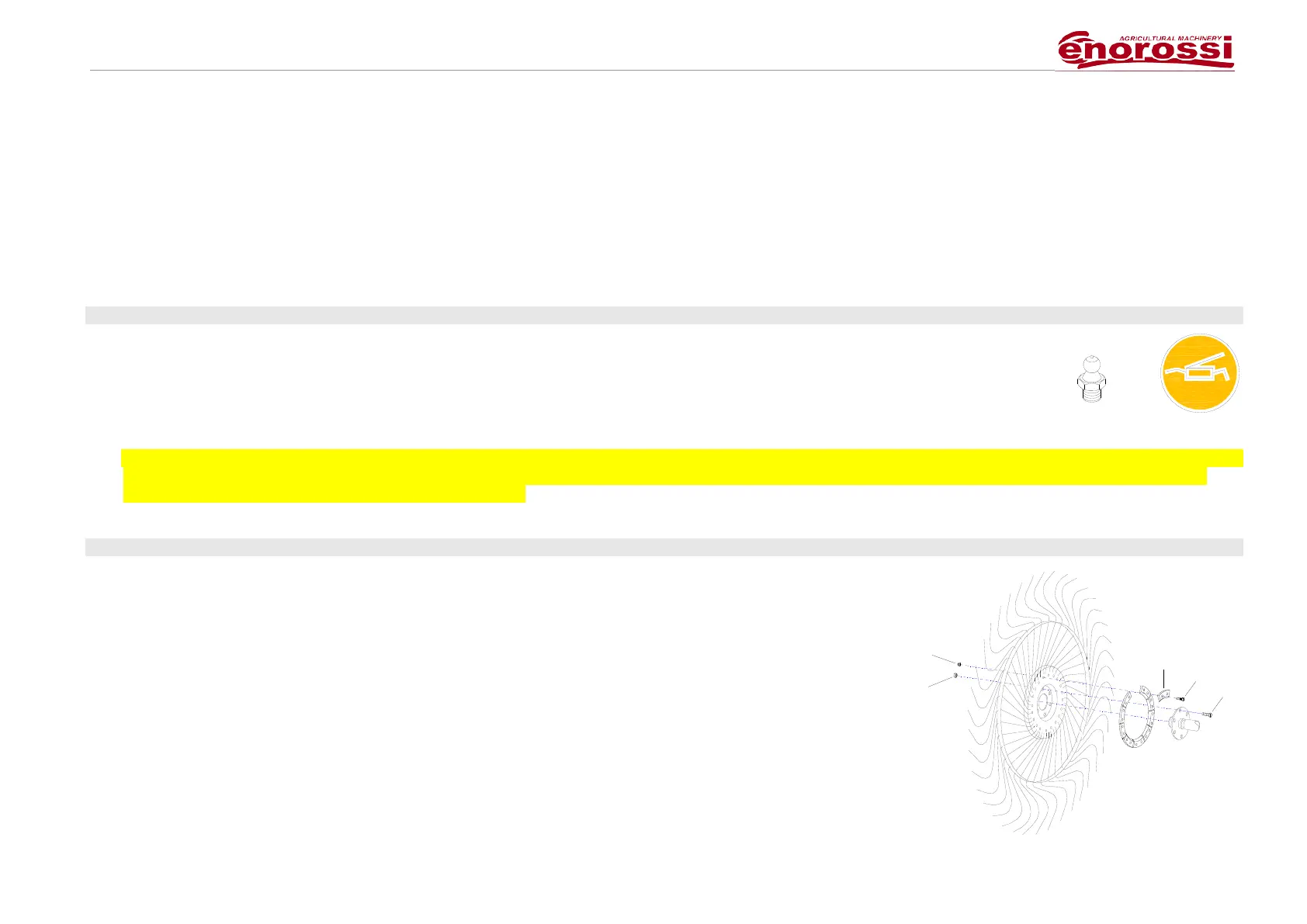

E4 Raked wheel and/or teeth replacement

• rake wheels: Should the replacement of rake wheels is required, you must completely remove the six locking

nuts (1), and the fastening screws (5). Now take the rake wheel out of its connection (or hub).

Place a new rake wheel, insert the six screws and then lock them using the respecting nuts.

• teeth: Should the replacement of teeth is required (for wear or damage), remove the block plate (3), by

removing the 2 locking nut (2). Then take off from their housings the screws (4) and finally remove plate and

teeth.

Loading...

Loading...