Do you have a question about the Envirovent MEV 160 and is the answer not in the manual?

Read and understand installation instructions before starting. Unit must be installed by a competent person.

Unit not for use by persons with reduced capabilities; supervision required. Children must not play with or clean the unit.

Wiring must comply with regulations. Unit requires continuous power, earthing, and a double pole switch for isolation.

Illustrates mains supply connection, local isolator, ventilation unit, and switch live options.

Provides detailed measurements for the unit and spigot connections.

Instructions on how to access the unit's interior for cleaning and maintenance.

Diagram showing the control panel buttons and indicator LEDs.

Continuous mechanical extract ventilation systems for fresh, healthy living environments.

Monitors humidity and automatically adjusts airflow rate based on rising levels.

Units feature a switch live function to engage boost mode.

Lists all items included in the product packaging.

Ensures the installation site and conditions are suitable before starting.

Steps for positioning the unit and removing the front cover.

Guide to inserting spigots and securely fixing the unit to the mounting surface.

Instructions for fitting external extract terminations and connecting ductwork.

Details on wiring the unit and preparing for commissioning.

Procedure to set and verify extract flow rates for boost and trickle modes.

Explains how the unit's fan speed increases with detected humidity.

How to activate and deactivate boost mode using a hardwired switch.

Instructions for manually activating boost and pairing remote controls.

Guide on how to replace the battery in the wireless remote control.

Details on extract spigot diameter, airflow rates, power consumption, and supply.

Graph illustrating the unit's static pressure versus air flow rate.

Instructions for cleaning the unit, including removing dust and debris.

Items to verify after the unit has been installed.

List of available spare parts and accessories with order codes.

Details on the two-year warranty, conditions, and exclusions.

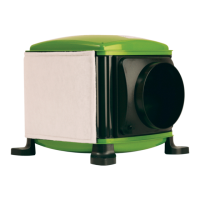

This document describes the EnviroVent MEV 160 & MEV 300, which are continuous mechanical extract ventilation systems designed to improve indoor air quality by removing humid, stale air from wet rooms and minimizing humidity transfer to other areas. These units are typically installed in a central location, with ductwork extending to the kitchen, bathroom, en-suite, utility, and other wet zones.

The MEV 160 and MEV 300 units operate continuously at a trickle airflow rate. They feature an Intellitrac® humidity tracking function that monitors humidity levels in the extracted air. When humidity rises, the airflow rate automatically increases to boost mode. Once humidity levels decrease, the system reverts to the programmed trickle setting. Both models include a switch live function, which, when engaged, activates boost mode. The units are available with either a wired boost switch or a wireless remote control for manual activation of the boost function.

| Brand | Envirovent |

|---|---|

| Model | MEV 160 |

| Category | Fan |

| Language | English |