FIKE CORPORATION

Page 22 of 32 Fike Explosion Protection System FM 3020541

10/06 P/N E06-051 Rev. 8

7.0 DECOMMISSIONING PROCEDURE / CHECK-LIST

The following procedure must only be performed

by a Fike qualified Service Engineer, who has

been assigned to prepare and complete the

decommissioning of the above referenced

Explosion Protection System.

Each step in the listed procedure must be adhered

to and completion/acceptance of this form is

mandatory. The Service Engineer must check off

each of the following steps. In the case of non-

compliance, the observed discrepancy must be

corrected before completion of the system

decommissioning.

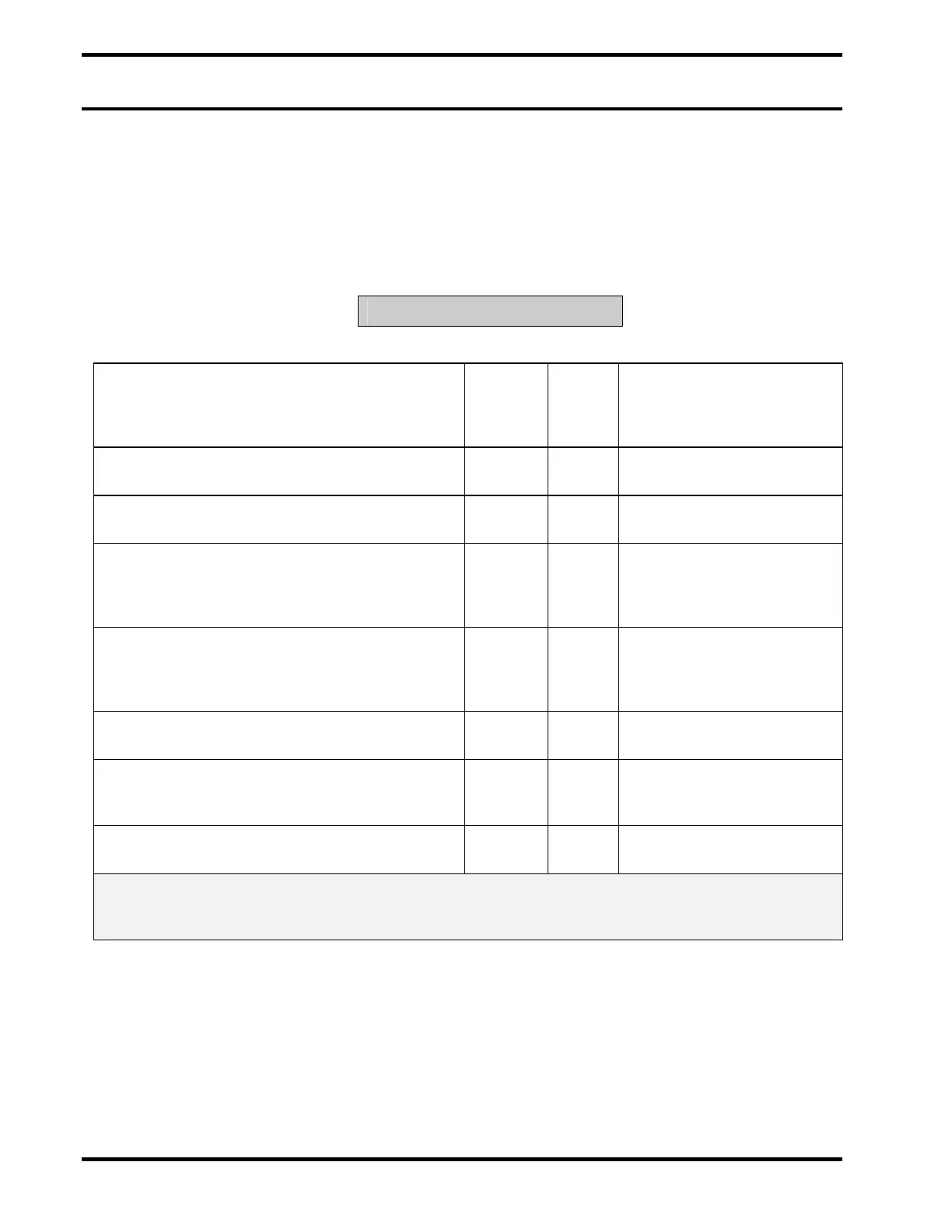

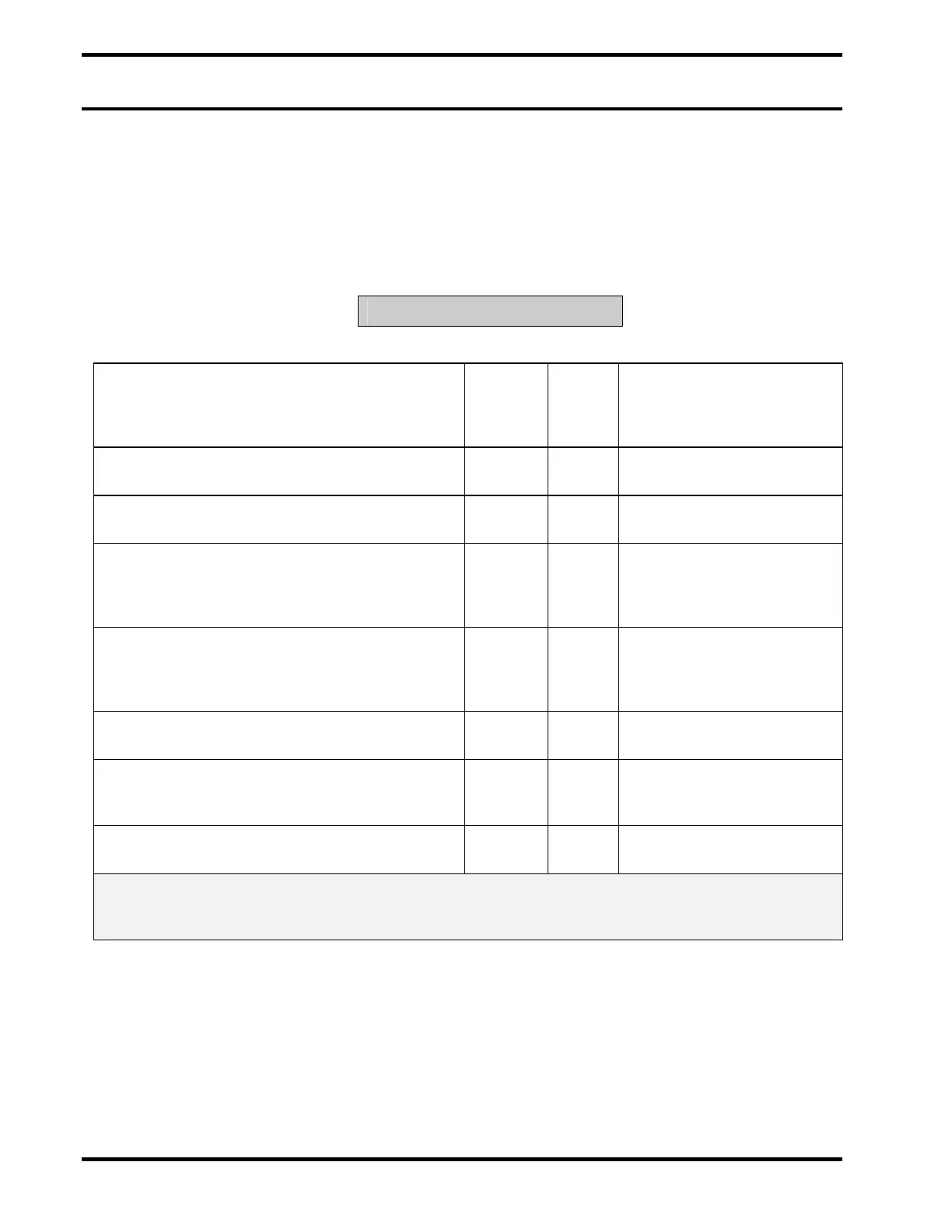

Exhibit 7-1 Decommissioning Steps

STEPS / DESCRIPTION

1. Use Fike system/project component location

diagram to record and verify the locations of

all Fike system components for each zone

and system.

pass fail Remark/

Note No.

2. Control panel to be disarmed/shutdown. pass fail Remark/

Note No.

3. All suppressor/valve actuators to be shunted. pass fail Remark/

Note No.

4. Each suppressor/valve container to be

depressurized.

Note: Do not ventilate nitrogen in a confined

space.

pass fail Remark/

Note No.

5. Power supply to the control panel to be

isolated by the customer and disconnected to

prevent accidental reconnection. Fike to

verify.

pass fail Remark/

Note No.

6. Control panel battery to be disconnected and

removed for proper disposal.

pass fail Remark/

Note No.

7. Each actuator is to be removed and placed in

a storage housing, to be either stored on site

or removed for proper disposal.

pass fail Remark/

Note No.

8. Verify that all suppressor/valve gauges are

reading zero, replace fill valve cap loosely.

pass fail Remark/

Note No.

ATTENTION: SYSTEM IS NOW DECOMMISSIONED AND READY

FOR DISMOUNTING BY THE CUSTOMER.

Loading...

Loading...