3. Adjust the calibration to the desired level by pressing (⇧) or (⇩). In this case, we want to

adjust the value to 5.4%. Press (⇧) 4 times quickly. Sensor reading has delay, so response

time may be slower.

4. Release the SP key. The value is now stored and the CO

2

sensor calibration has been mod-

ified.

13.3.5 O

2

sub-menu (only MAW

®

with a built-in gas mixer)

Press (⇨) on O

2

to enter the O

2

sub-menu.

First item in the O

2

sub-menu is O

2

sensor calibration.

Calibrate holding down the SP key; use (⇧) and (⇩) to adjust.

Move to the next sub-menu item with (⇩) or one step up with (⇧).

Toggle O

2

regulation ON/OFF by holding the SP key and pressing (⇧) or (⇩).

The default status for the O

2

control is OFF.

Press (⇩) to move to the next item in the O

2

sub-menu.

N

2

flow rate is shown. This is the amount of N

2

gas put into the system while regulating. The

volume is shown in l/hour. It cannot be adjusted. Normally it will fluctuate along with the

O

2

regulation.

Press (⇩) to move to the next item in the O

2

sub-menu:

N

2

internal pressure rate is shown. The value is in bar. It must be between >0.2 and ≤0.8 bar

(2.90 – 11.60 PSI) at all times. It cannot be adjusted on the incubator – it must be adjusted

on the external gas regulator.

Example – how to calibrate the O

2

:

Using a suitable and calibrated device on one of the gas sample ports, the real O

2

concentra-

tion has been recorded to be 5.3%. Both ports should be used during calibration.

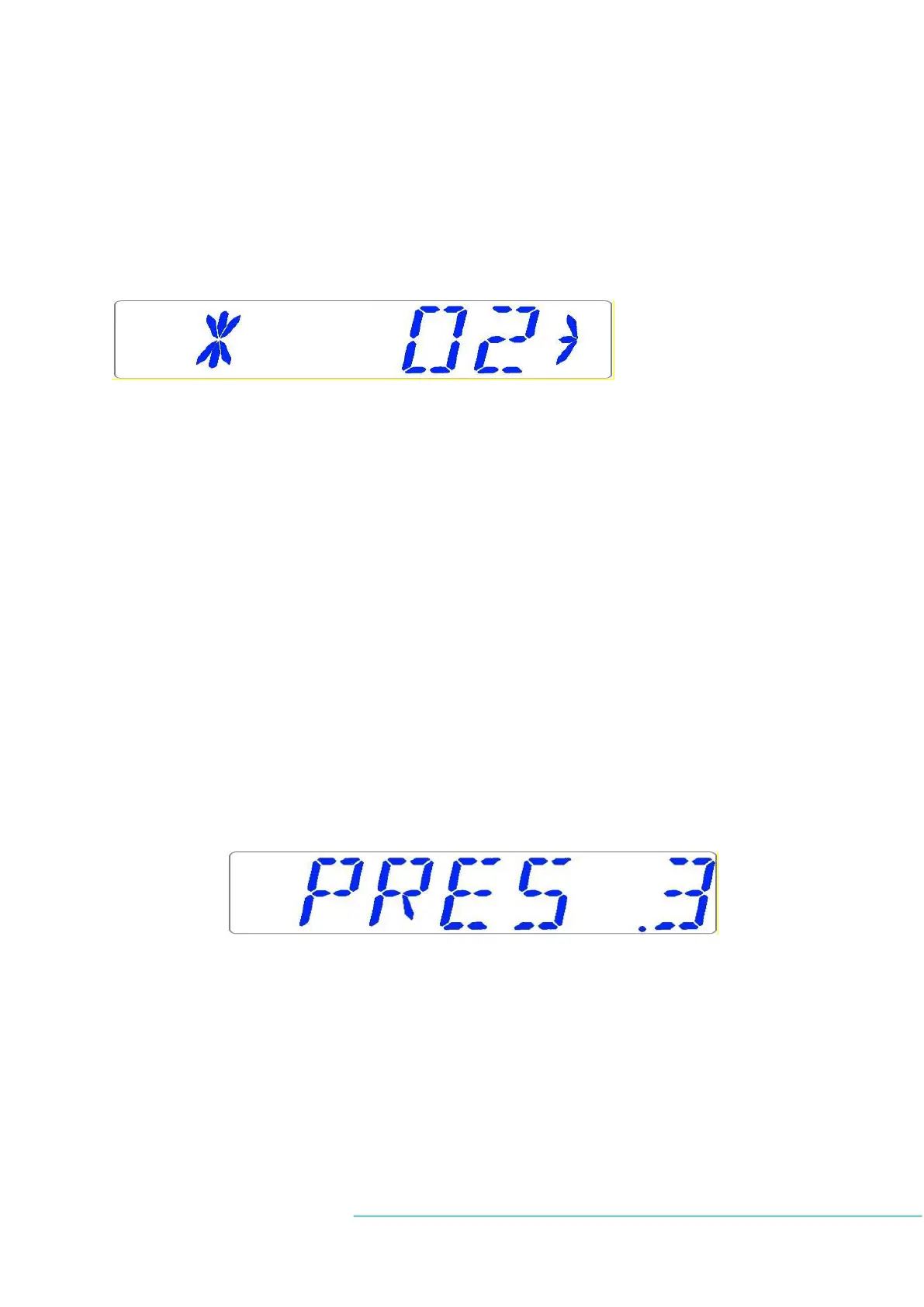

Loading...

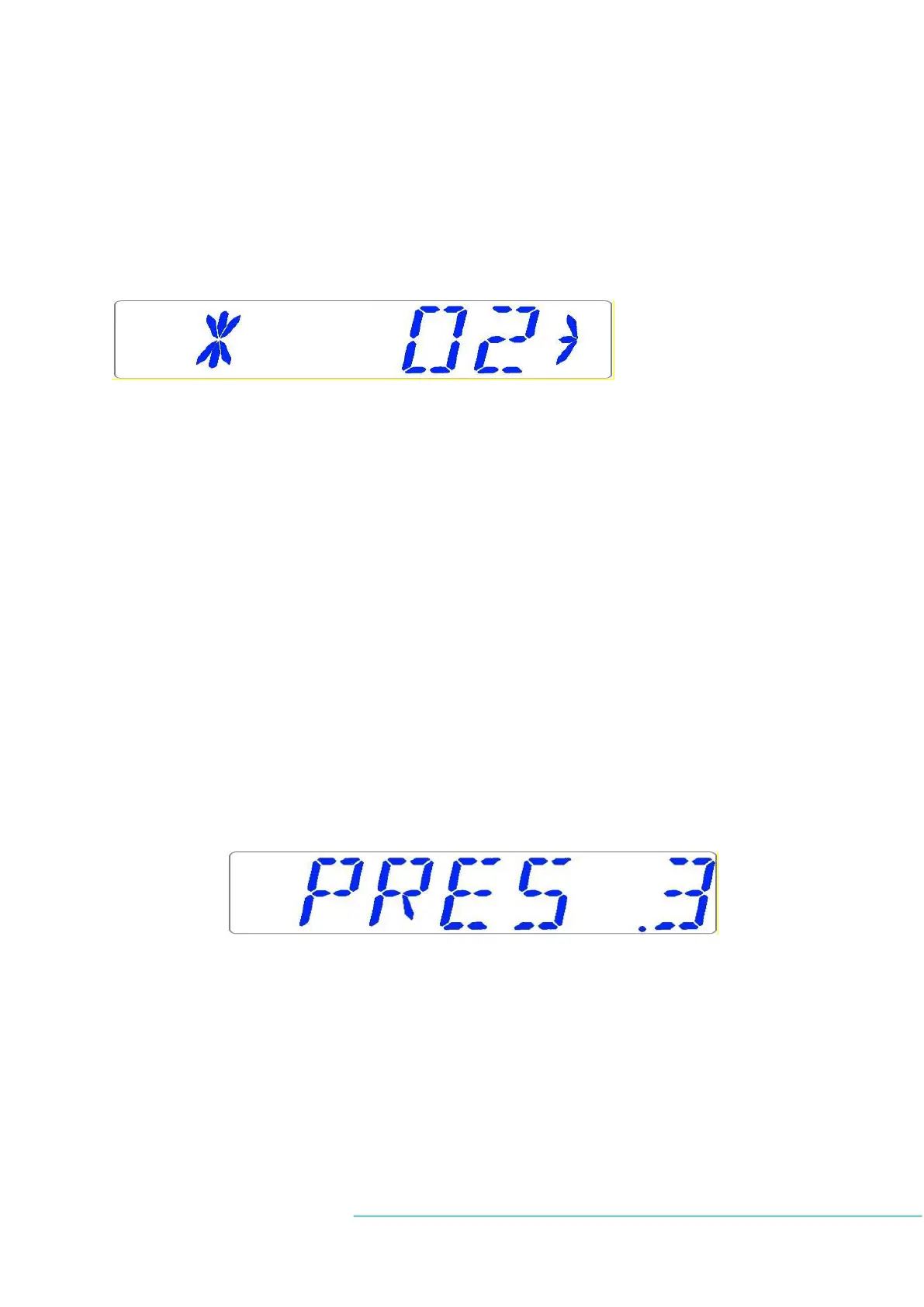

Loading...