ZIRCON

18

INSTALLATION

Water connection

Pressure and temperature

Starting the machine

The Installation of the machine to a water mains connection must be done by a qualied person.

Rinse around 20 liters of water from the main water supply before connecting the machine to the water

connection.

Connect the inlet hose that is assembled in the machine to the main water supply, which should have

a 3/8” male connection tted with a shut-off valve, tighten it with a wrench.

Use safe drinking water with hardness between 5ºfH and 8ºfH (French hardness degrees). If the value

is below this limit, the presence of corrosion of hydraulic components is a possibility. If the value is

higher than this limit, the presence of lime in the boiler will increase. In both cases the operation of

the machine and coffee quality will be affected negatively.

If necessary, connect the machine to a water softener or remineraliser to reduce water hardness. Use

the exible hose that is included in the accessory box of the machine.

Connect one end of the corrugated tube to the drain cup in the machine, connect the other to the

main drainage tube at the installation area.

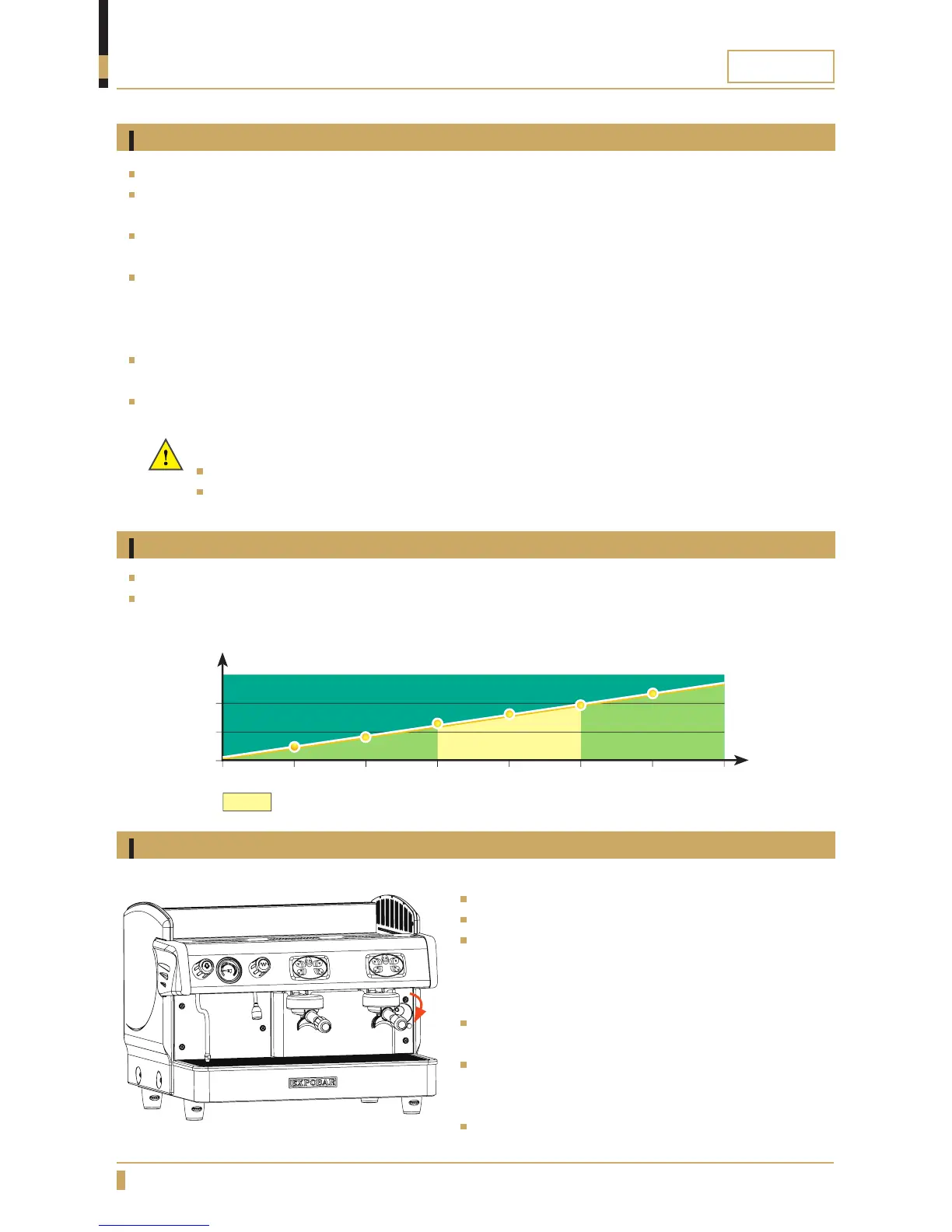

Boiler temperature and pressure are directly related (see Fig. 01).

Machine is tted with a pressure gauge that will display the boiler pressure, if the machine is tted

with a display it will also indicate boiler temperature.

Relationship between boiler pressure and temperature

Standard pressure and temperature

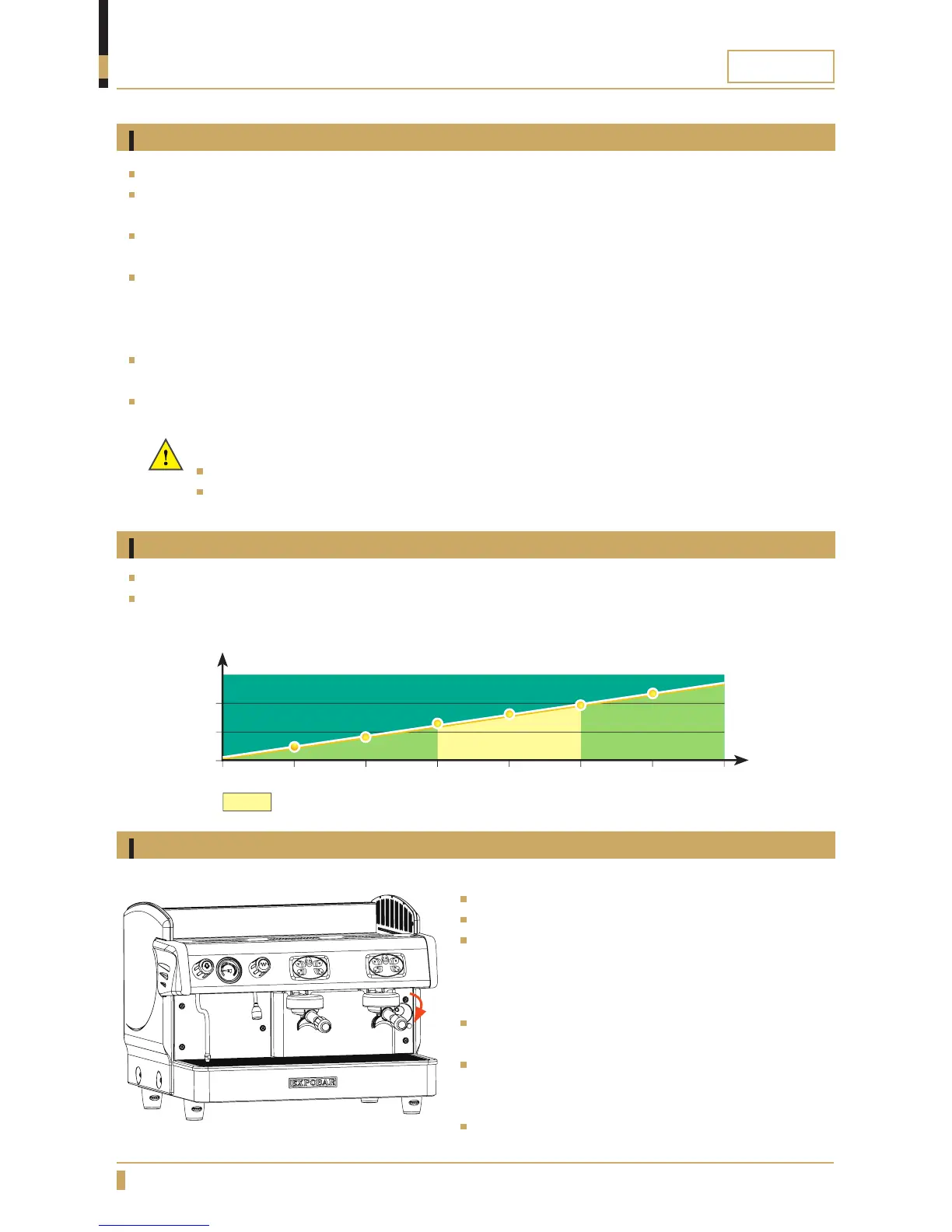

Open the external supply of water to the machine.

Turn on the main power switch.

Press a drink button at the control panel on each

group, wait until water comes out continuously from

each of them. This way the heat exchangers in the

machine will be correctly lled.

Open the steam tap to release the air trapped in the

boiler.

The red lamp indicates that the boiler is heating.

The lamp switches off when the machine reaches

operating temperature.

The machine is now ready to use.

0.7

110

115

120

125

0.8 0.9 1 1.1 1.2

o

C

BAR

Important:

Only use the hoses supplied with the machine. Never reuse hoses.

Make sure that the drainage tube is not twisted and ensure that the entire tube is below the

level of the drain cup.

Fig. 01

Loading...

Loading...