CHAPTER 27

PAGE 8

MAINTENANCE MANUAL EXTRA 300/SC

PAGE DATE: 1. August 2014

I M P O R T A N T Ensure that the rod ends of each control rod are ex-

actly aligned to each other (see Table 1) after adjust-

ment. This particularly applies for the control rod (1,

Figure 6), which must allow the torque tube to rotate.

I M P O R T A N T Observe that the rod ends joined to the rocker type

bellcrank should be adjusted long enough not to obstruct

the travel.

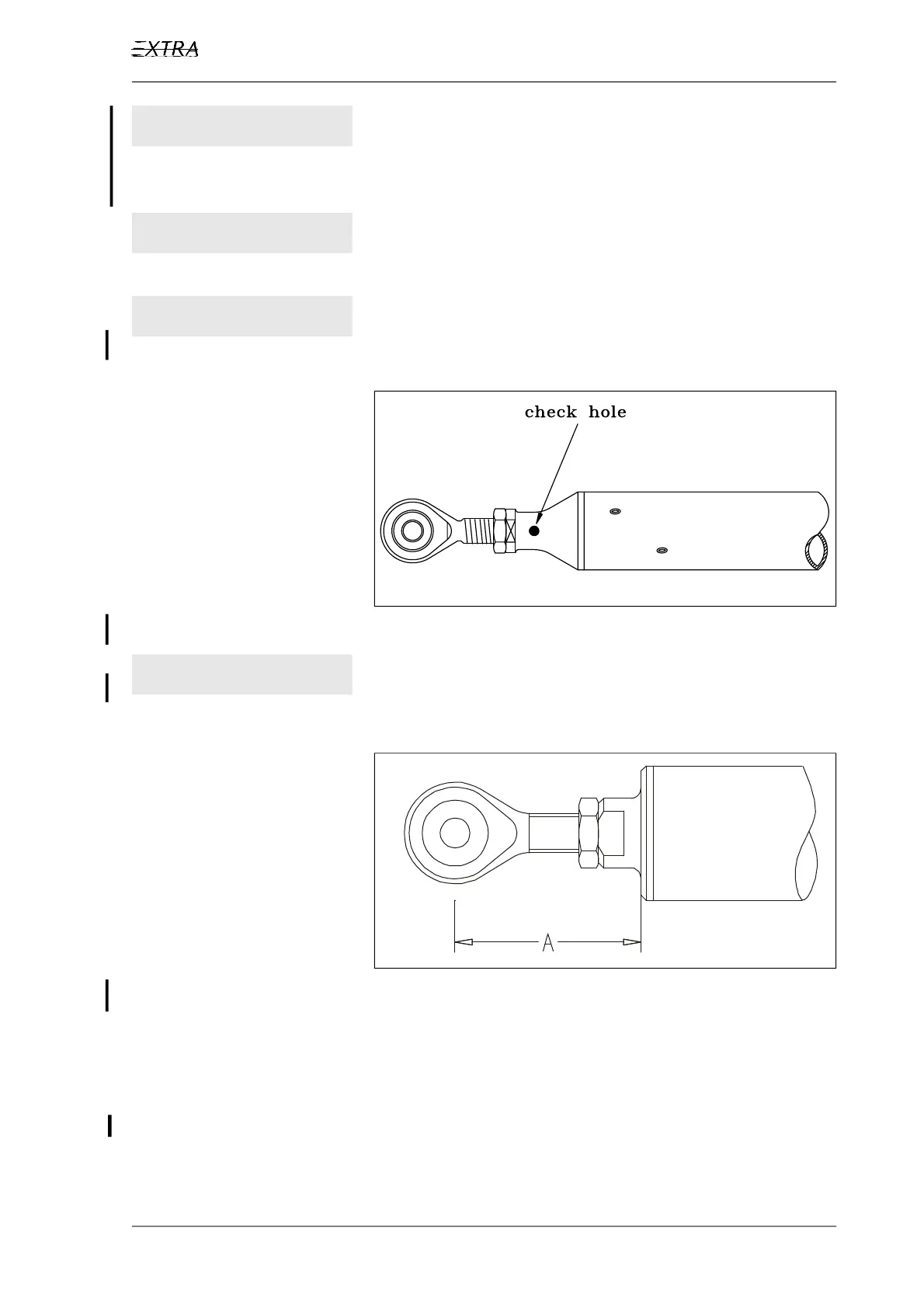

I M P O R T A N T Ensure that the threaded rod is visible in the check hole

(Figure 7, Sheet 1) in any case, if aluminium rods shall

be adjusted.

Figure 7, Sheet 1 Aluminium Control Rod Check Hole

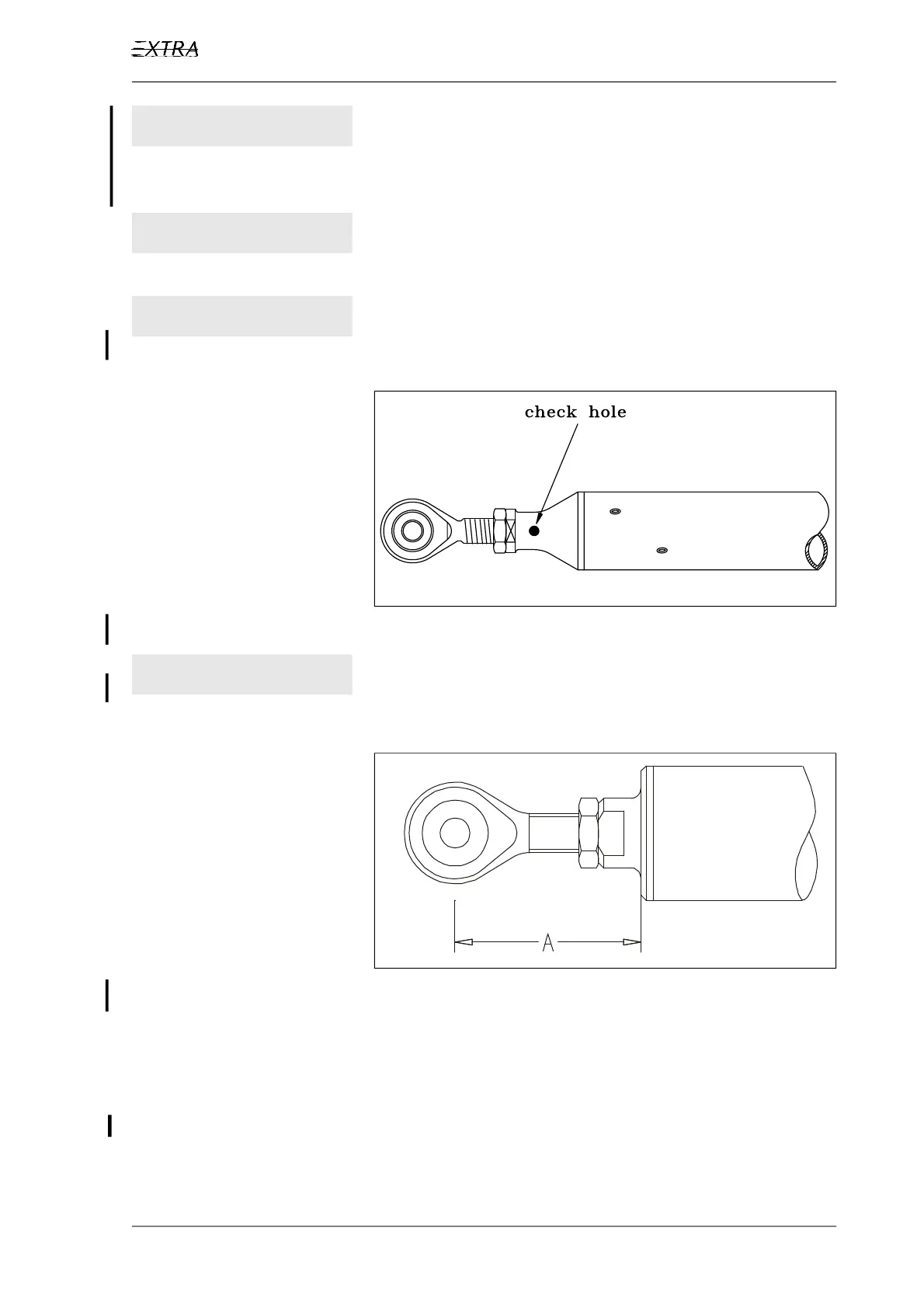

I M P O R T A N T Ensure that the value "A" (Figure 7, Sheet 2) does not

exceed 43 mm in any case, if carbon rods shall be ad-

justed.

Figure 7, Sheet 2 Carbon Control Rod Maximum Adjustment

4 Turn the rod end in the desired direction to change the length.

5 Ensure that the rod end is in proper alignment with the re-

spective control lever and tighten the check nut.

6 Reinstall the control rod per Chapter 27-00-01.

7 Ensure that the control rods don't jam when the control sticks

are moved between the extreme positions.

Loading...

Loading...