Installation

312

8.

INSTALLATION

Connection of the control and communications signals

296

DDS

HARDWARE

Ref.1310

Interconnection

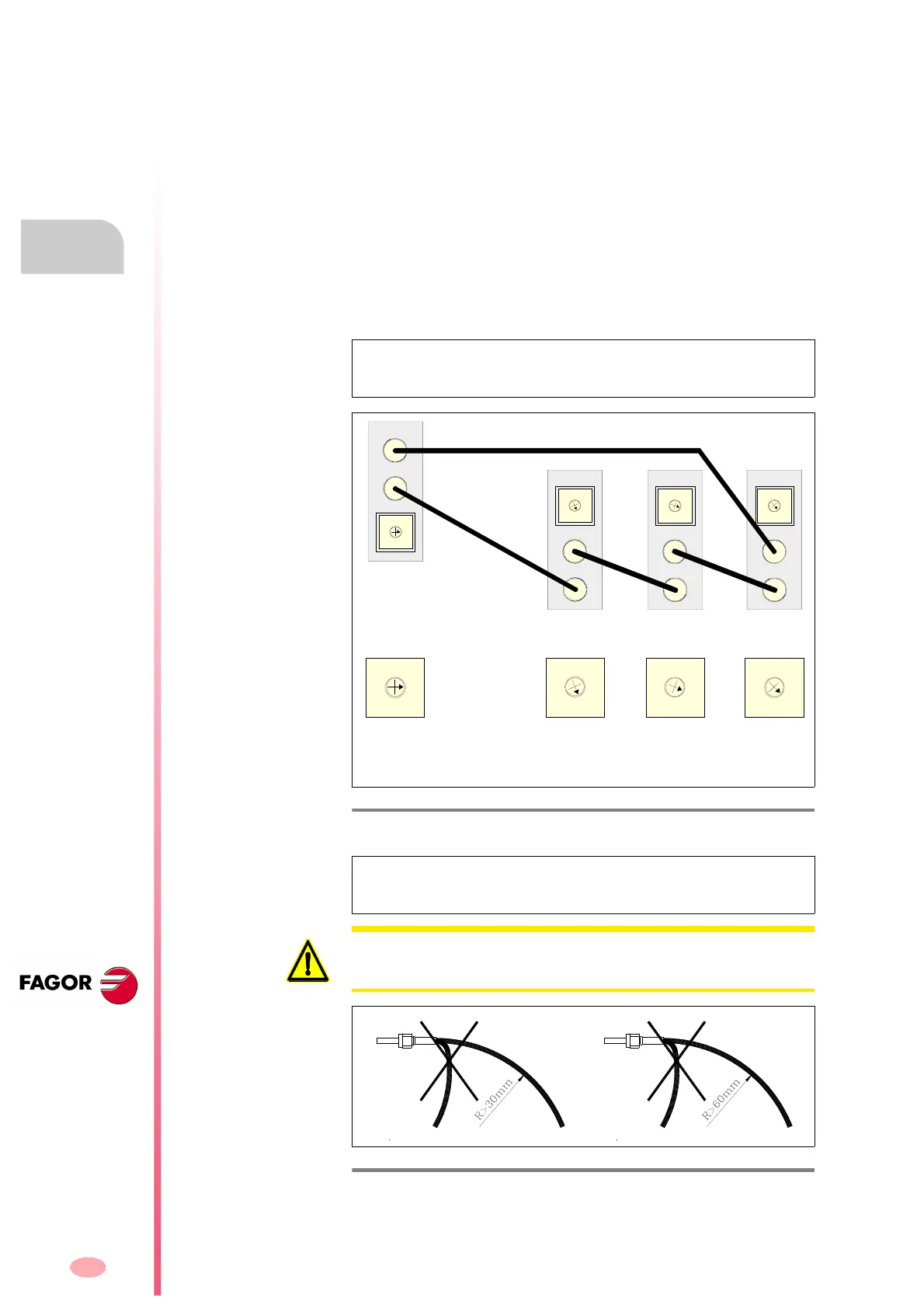

Connect in the SERCOS ring all the drives that will be governed by the

CNC.

With each fiber optic line, connect the OUT terminal of the first drive

with the IN terminal of the next adjacent drive.

Repeat this procedure with the second drive and so on up to the last

drive.

Connect the OUT terminal of the last drive with the IN terminal of the

CNC.

Connect the IN terminal of the first drive with the OUT terminal of the

CNC.

When all these connections have been made, the ring will be closed. See

figure

F. H8/24.

NOTE. With each drive, FAGOR supplies a fiber optic line to connect it to

its adjacent module and, upon request, the rest of the required optical fi-

ber. See chapter

7. CABLES.

F. H8/24

General connection diagram for the SERCOS ring between the CNC and

the drives.

NOTE. Note that if the machine has two separate servo drive system

(each with its own power supply) and a single CNC, the same ring must

interconnected all the drives of the machine.

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

IN

OUT

NODE

IN

OUT

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

NODE

IN

OUT

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

NODE

IN

OUT

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

NODE

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

CNC SPINDLE X AXIS Y AXIS

Node=2Node=1Node=3Node=0

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

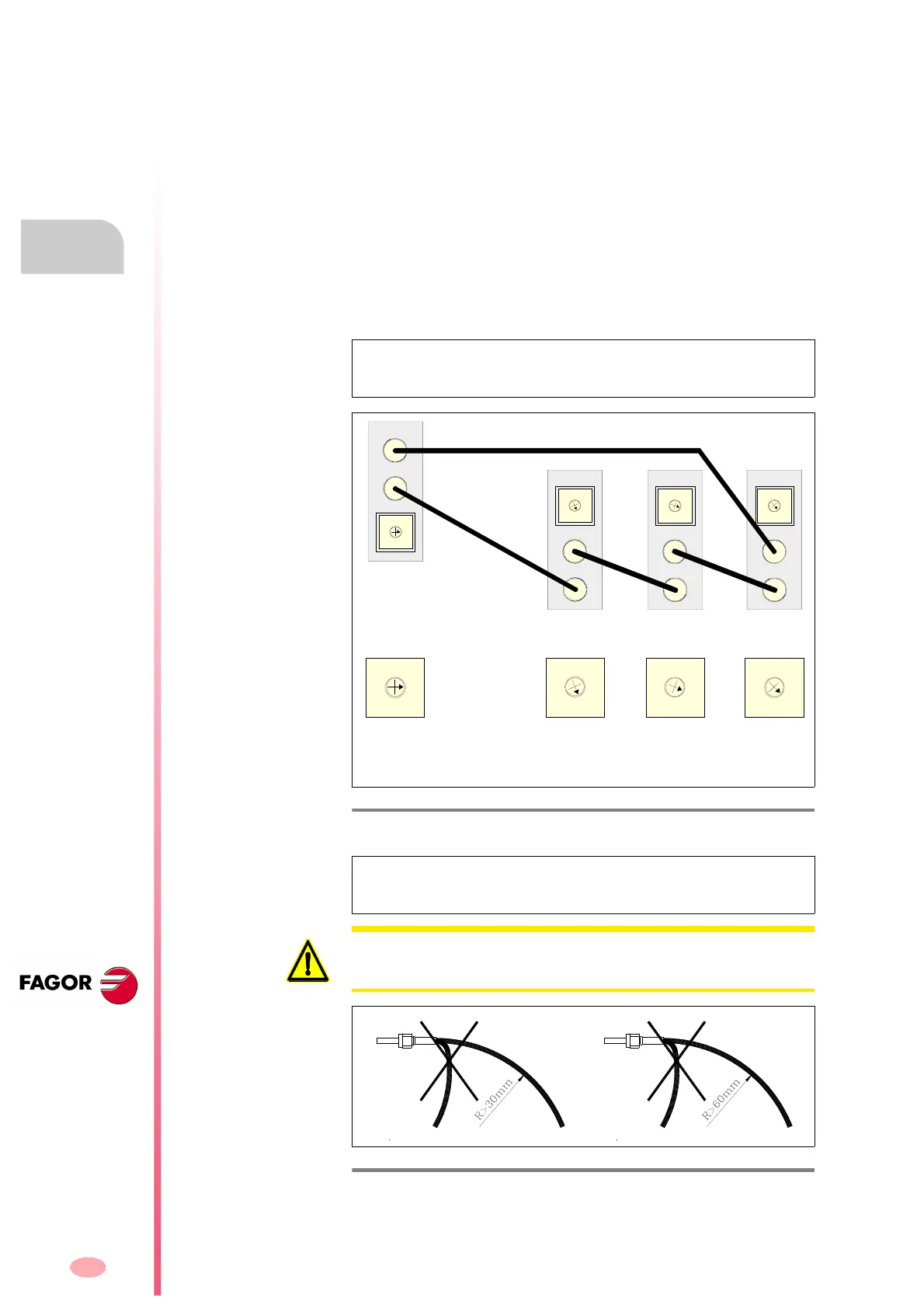

Note. Remember that for sections longer than 40 meters, you must use

the fiber optic cable (SF0-V-FLEX).

WARNING. The bending radius of fiber optic cables SF0 and SF0-FLEX

must always be more than 30 mm. For SF0-V-FLEX cables, this radius

must be more than 60 mm.

F. H8/25

Minimum bending radius. A. Fiber optic cables SF0 and SF0-FLEX. B. Fi-

ber optic cable SF0-V-FLEX.

Loading...

Loading...