10.

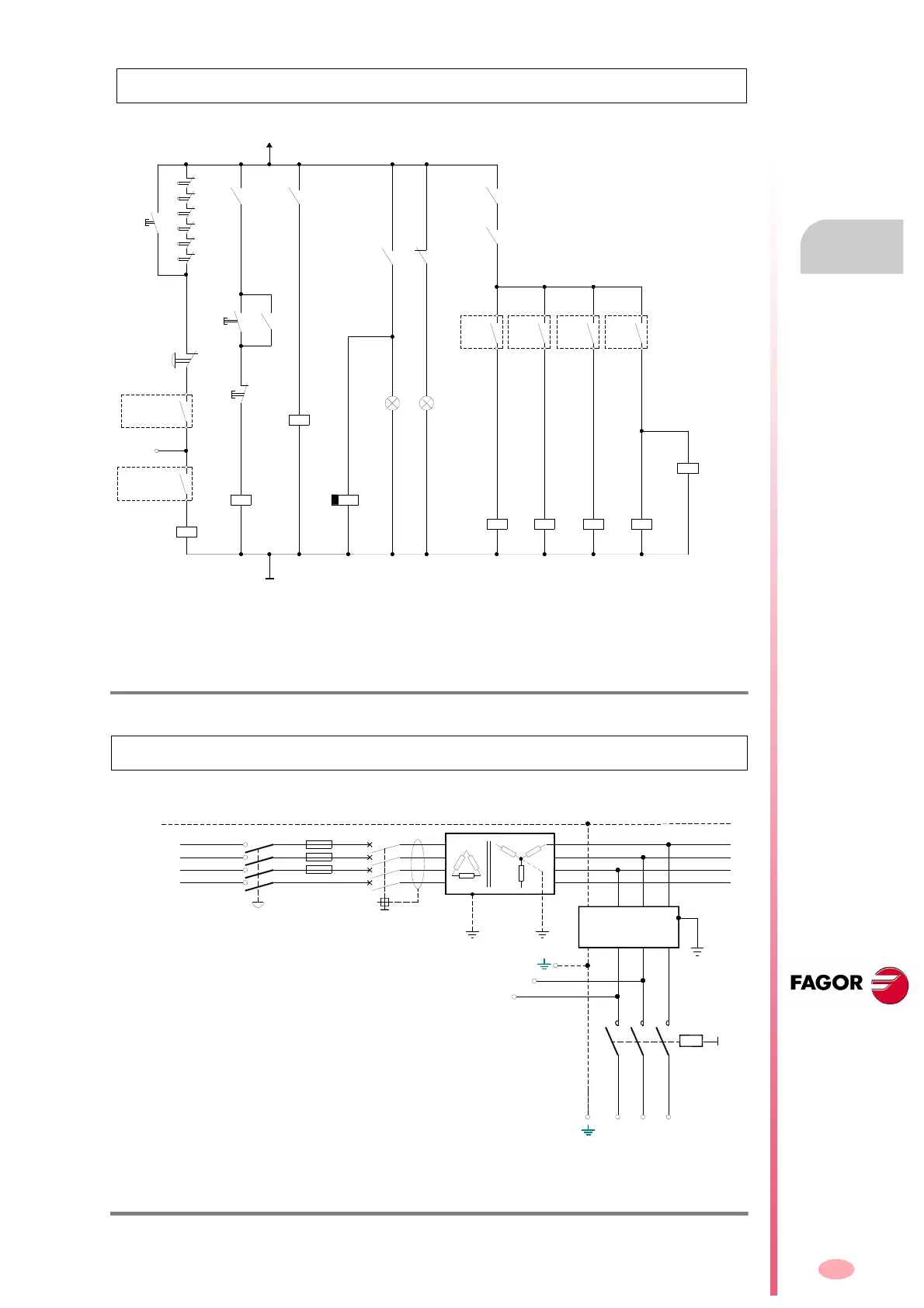

F. H1 0/1 0

F. H1 0/11

Note. CNC EMERG. will always be assigned to I1/O1 of the PLC with an 8055/55i CNC. With an 8070

CNC, it may be assigned to any I/O of the PLC. The contacts associated with relays - KA2, - KA3, -

KA4, - KA5, - KA6 and - KA7 are shown inside a circle in figure

F. H1 0/9 and the contactor - KM1 in fig-

ure

F. H1 0/11 .

OPERATION DIAGRAM. PS-65A

Note. The relay - KA3 uses delayed

deactivation (t seconds) maintaining

the DRIVE ENABLE control signal

active for a few seconds to maintain

motor torque while the vertical axis

holding brake is enabled.

See parameter GP9 in the

“man_dds_soft.pdf” manual

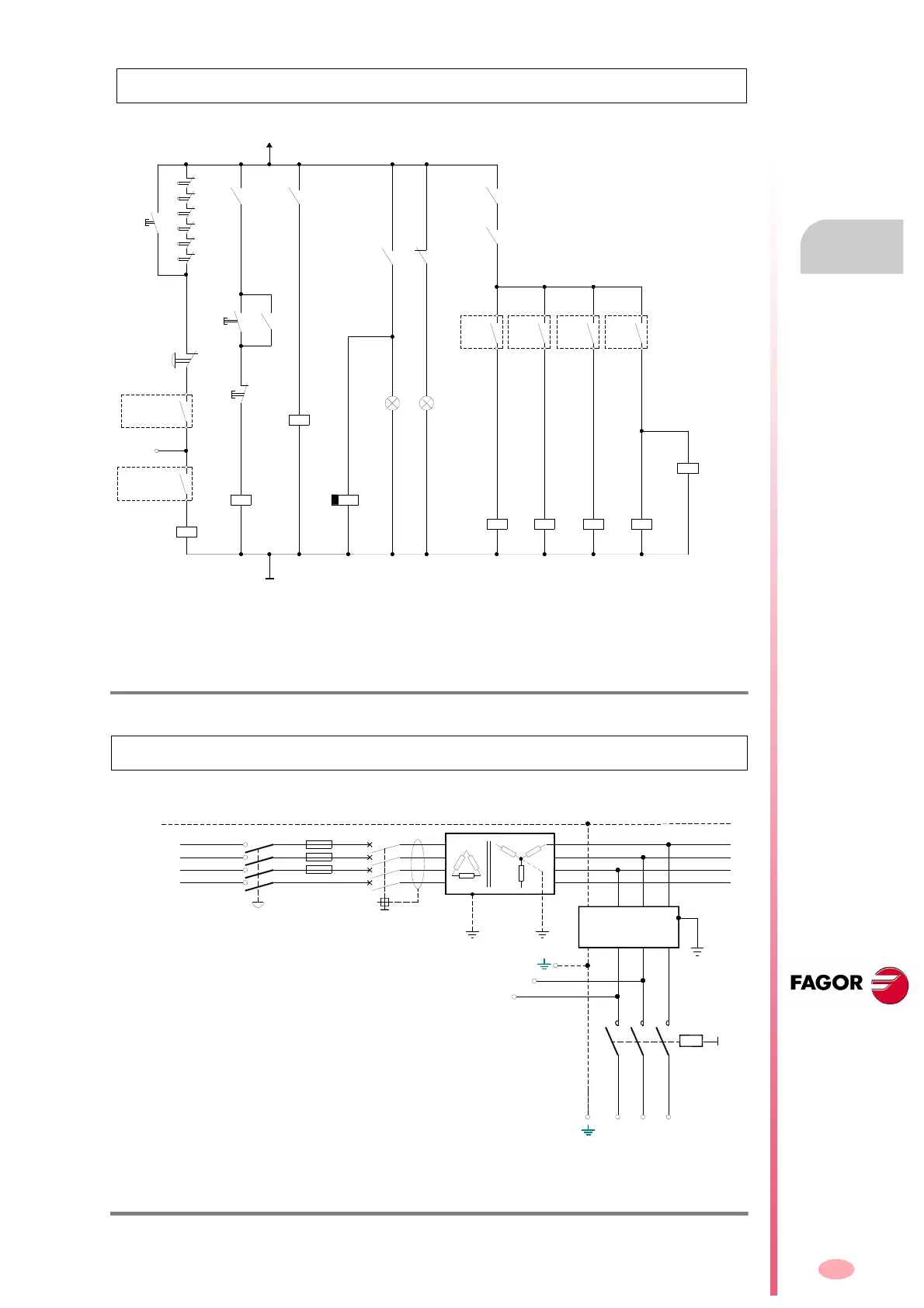

PE

- S1

MECHANICAL

MAIN SWITCH

- F3

- F4

- F5

MAINS FILTER 130A

L1

L3L2L1

3x400-460 VAC

2x400-460 VAC

R

S

T

R

S

T

CONTACTOR

- KM1

L2

N

- Q1

DIFFERENTIAL

BREAKER

WARNING. When using an isolating transformer, the secondary must be

connected in star and its middle point must be connected to GND.

POWER MAINS

IT A MUST TO USE FUSES

TO THE POWER CONNECTOR

PS-65A POWER SUPPLY

TO THE X1 CONNECTOR

APS 24 AUXILIARY

POWER SUPPLY

Note. Observe that having the main key - S1 closed, although the

power contactor - KM1 is open, the external APS-24 auxiliary

power supply remains connected through its connector X1 to feed

the control circuits of the drive.

GENERAL DIAGRAM. PS-65A

Loading...

Loading...