10.

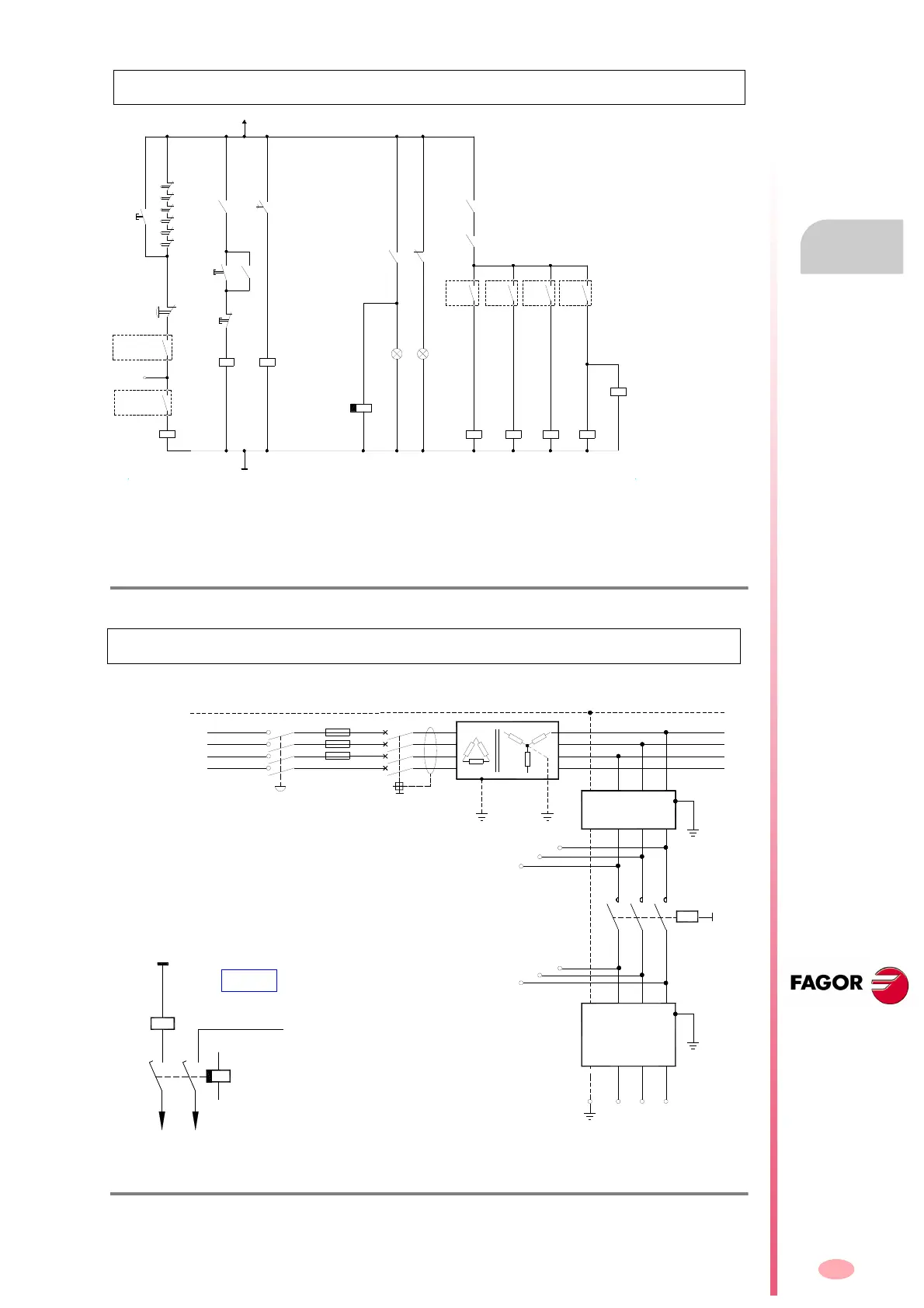

F. H1 0/1 9

F. H1 0/2 0

Note. CNC EMERG. will always be assigned to I1/O1 of the PLC with an 8055/55i CNC. With an 8070

CNC, it may be assigned to any I/O of the PLC. The contacts associated with relays - KA2, - KA3, - KA4,

- KA5, - KA6 and - KA7 are shown inside a circle in figure

F. H10/18 and the contactor - KM1 in figure

F. H10/20.

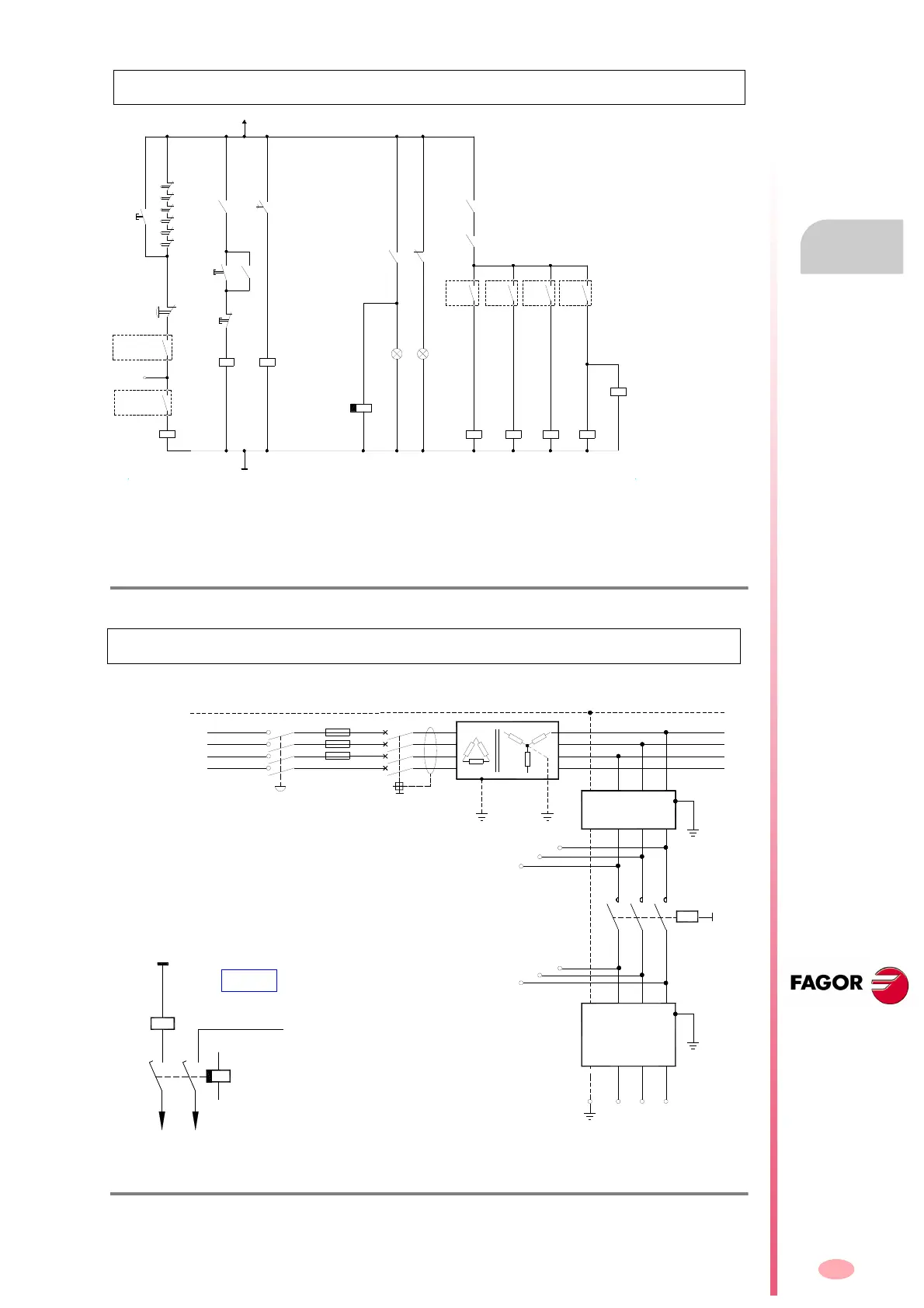

OPERATION DIAGRAM. RPS-XX

Important. The relay - KA3 acts simultane-

ously upon contact KA3,1 to excite the coil of

contactor - KM1 and upon the auxiliary contact

KA3,2 (see previous figure) associated with

the PWN ENABLE (pin 4 of X6) of the RPS

power supply. Make sure that the time t used

to program the delay of relay - KA3 associated

with contacts KA3,1 and KA3,2 is

greater than

the braking time (full stop) to permit returning

all the excess energy to mains while braking.

The delay disconnec-

tion time “t” to be pro-

grammed at relay - KA3

must be GREATER

THAN the total amount

of time required to

brake the motor to a full

stop.

PE

- S1

- F3

- F4

- F5

MAINS FILTER XXA

CHOKE RPS-XX

w1 v1 u1

w2 v2 u2

L2

L1L2L3

TO THE X1 CONNECTOR

RPS-XX POWER SUPPLY

TO THE 1 POWER CONNECTOR

RPS-XX POWER SUPPLY

3x400-460 VAC

3x400-460 VAC

TO CONNECTOR 2 OF THE

RPS-XX POWER SUPPLY

- FEEDBACK CONNECTOR OF THE

AUXILIARY SIGNAL LINE-

3x400-460 VAC

R

S

T

R

S

T

CONTACTOR

KM1

L1

L3

R

S

T

N

INDUCTANCE

- Q1

WARNING. When using an isolating transformer, the secondary must be

connected in star and its middle point must be connected to GND.

IT A MUST TO USE FUSES

POWER MAINS

MECHANICAL

MAIN SWITCH

DIFFERENTIAL

BREAKER

GENERAL DIAGRAM. RPS-XX

Note 1. Observe that having the main switch - S1

closed, although the power contactor - KM1 is

open, the internal auxiliary power supply remains

connected to the unit through its connector X1 to

feed the control circuits of the drive.

See fig.a

fig.a

Loading...

Loading...