ALYA INSTALLATION AND USER’S MANUAL - EN

Edition 2.0 Sept 2018 Pag. 19 di 32

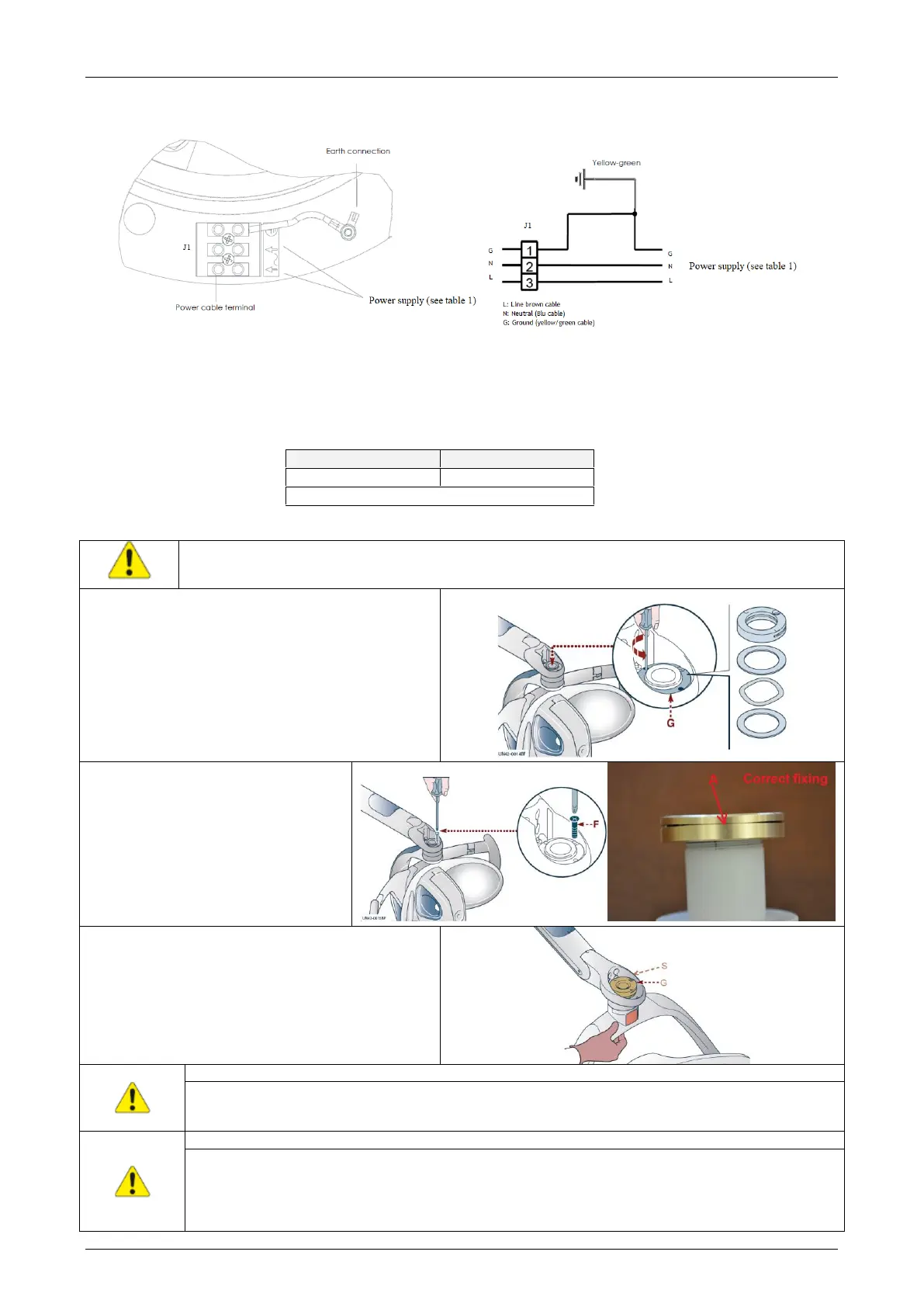

3.2.8.1 Electrical drawing – floor mounting without transformer

3.3 HEADLIGHT INSTALLATION

3.3.1 Mechanical Requirements

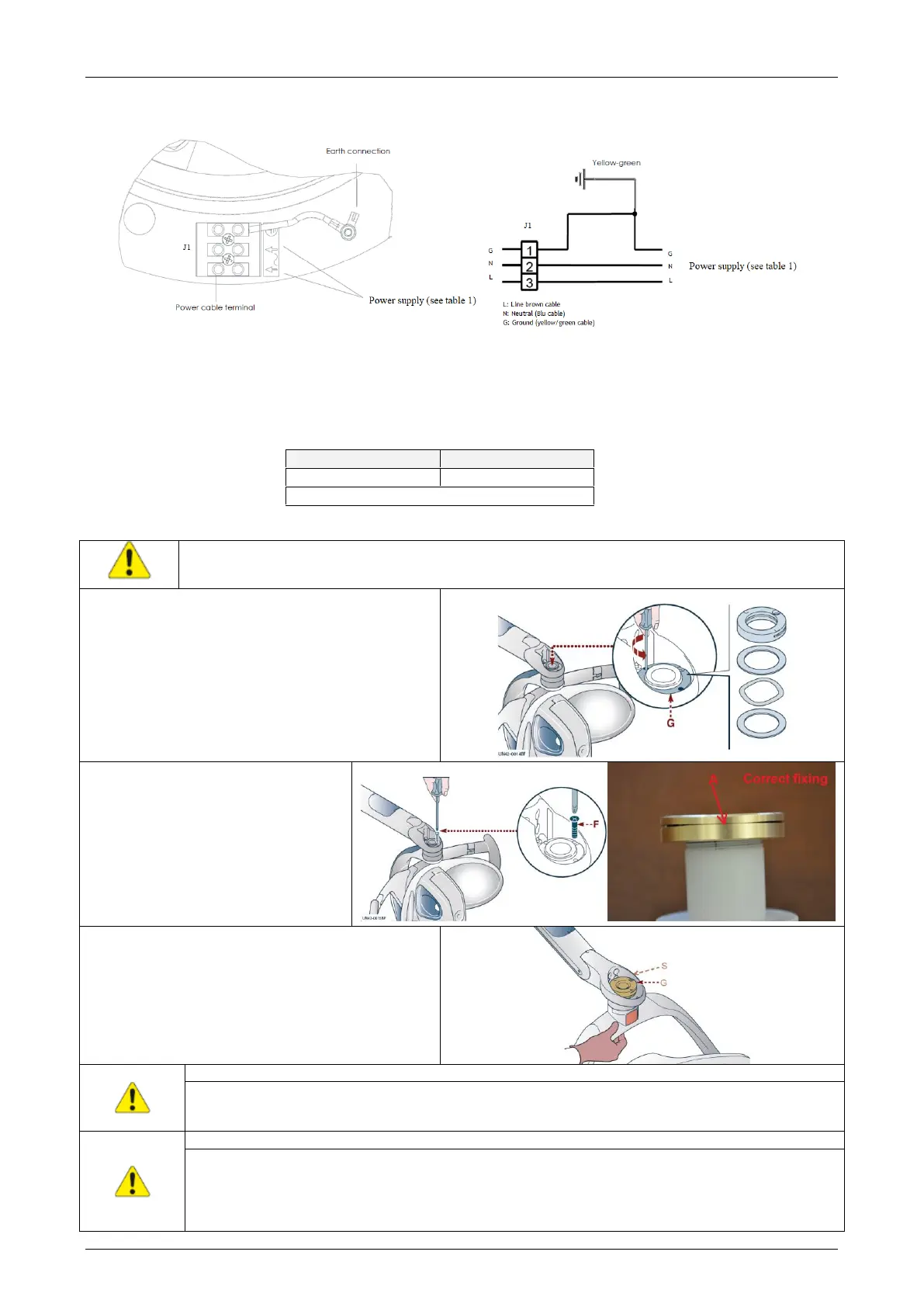

For mechanical connection an adequate space for the pin in the head and the nut identified as G.

The support system must be designed to support the following loads, multiplied by the safety factors outlined

by IEC/EN 60601-1 and IEC/EN 80601-2-60.

For the mechanical connection apply the following procedure:

Warning for danger of falling of suspended mass.

Strictly Follow the instruction to avoid the head to detach from the support.

1 -Support the head and insert the washers in the

threaded pin according to the sequence in the

figure.

2 - Insert ring nut G according to the sequence

indicated in the picture and screw in with

adequate equipment. The ring nut must be

screwed in to give the correct rotational force to

the head.

3 – Screw the safety screws F until

the cut (A) into the brass nut is

completely closed.

4 – take care to leave free space around the nut G

and the support S, to avoid any friction when the

head is rotating.

Fail to comply with this procedure could lead

in falling of the headlight.

The central arm without the head load tends to rise in a sudden manner with the risk of

knocking against parts of the body. During the entire installation, keep the central arm in

position and do not release it until head installation is complete.

Warning for danger of suspended mass falling

Only use screws supplied by FARO.

Screw in the safety screws together.

Before removing the nut (G) ALWAYS remove the safety screw F. NEVER unscrew the nut (G)

with the screws F mounted. Fail to comply with this procedure could damage the plastic

threated PIN of the headlight with possible detach of the headlight.

Once mechanical connection is complete, complete electrical wiring.

Loading...

Loading...