7.3 During operation

Locate and delimit the working area.

Make sure that no one is within the working area of the crane. Do not stop and

do not pass in the delimited area.

Choose the correct control position, making sure to have the complete visibility of

the

working area.

Stabilize the vehicle on a horizontal plane with a maximum tolerance of 1,5

degrees.

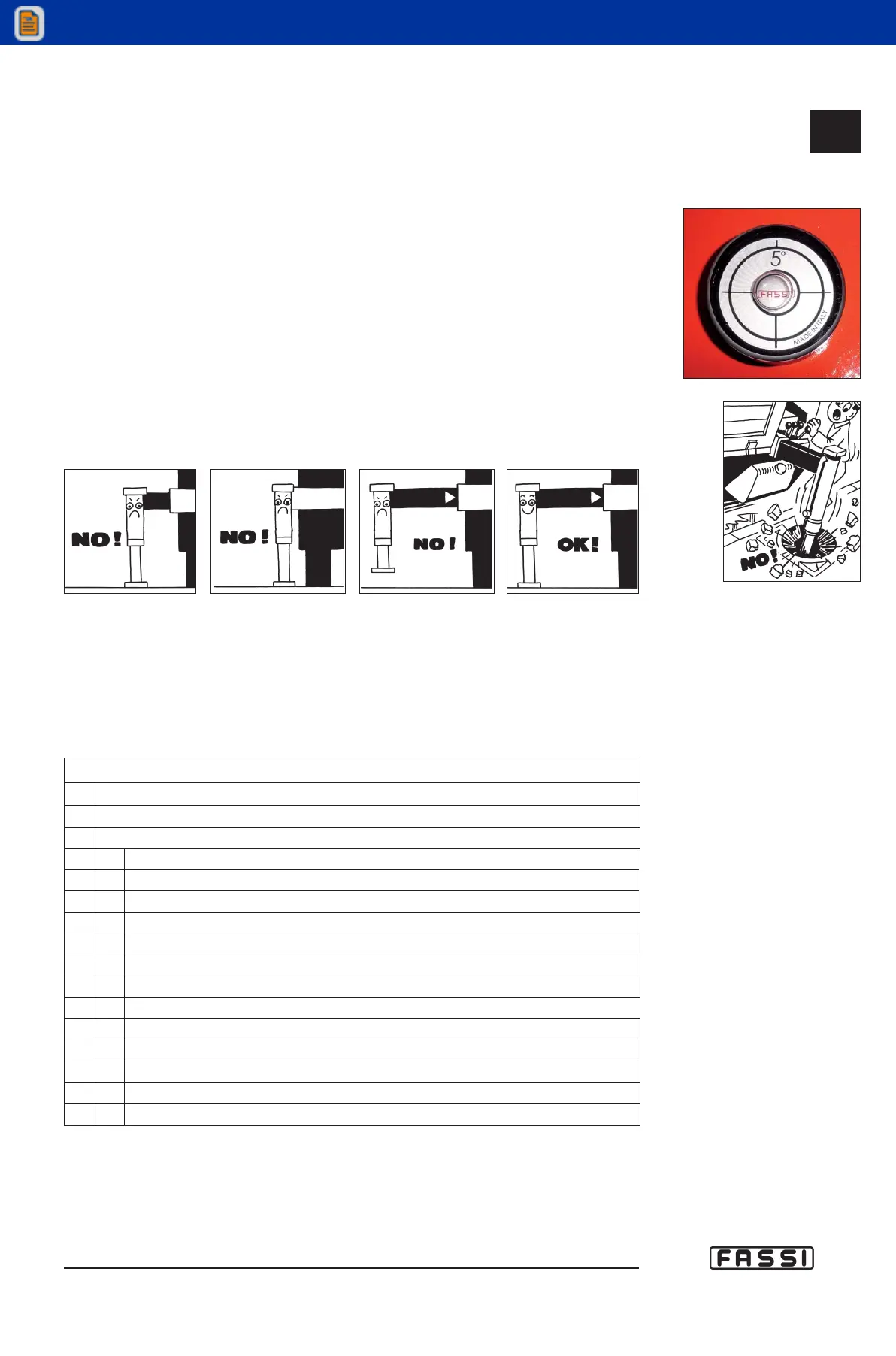

Check the vehicle inclination on the levelness indicator. The bubble must

be contained in the internal circle, and in any case it doesn't must to come out from

the external circle.

Make sure that the outrigger rams rest on a solid base. If necessary use larger

outrigger base plates (available on request) to avoid sinking. If you adopt other

means, make sure that they are suitably sized for the load they must bear.

(!) ATTENTION (!)

The stability of the unit (crane-vehicle) is only guaranteed by the complete

lateral extension of the outriggers and by the observance of the capacity

plates.

The values of the support force F are indicated in the table at paragraph "2.3 Technical

Data". Just as an indication it's enclosed the below table.

7.3

WARNING AND

INSTRUCTIONS

GRU FASSI

ADMITTED PRESSURE ON THE GROUND (Load capacity of the ground) - Rif. DIN 1054

A Made ground, not compacted artificially

B Asphalt

C Compact ground, not removed

1. Mud, peat, marshy ground

2. Not compacted ground, adequately solid

From fine to middle sand

From thick sand to gravel

Shattered and compacted stones

3. Compact ground

Wet

Soft

Compact

Half - solid

Hard (solid)

4. Rock

Eroded

0 - 10 daN/cm²

20 daN/cm²

0 daN/cm²

15 daN/cm²

20 daN/cm²

25 daN/cm²

0 daN/cm²

4 daN/cm²

10 daN/cm²

20 daN/cm²

30 daN/cm²

100 daN/cm²

Loading...

Loading...