SS01 Freecut from the sliding table

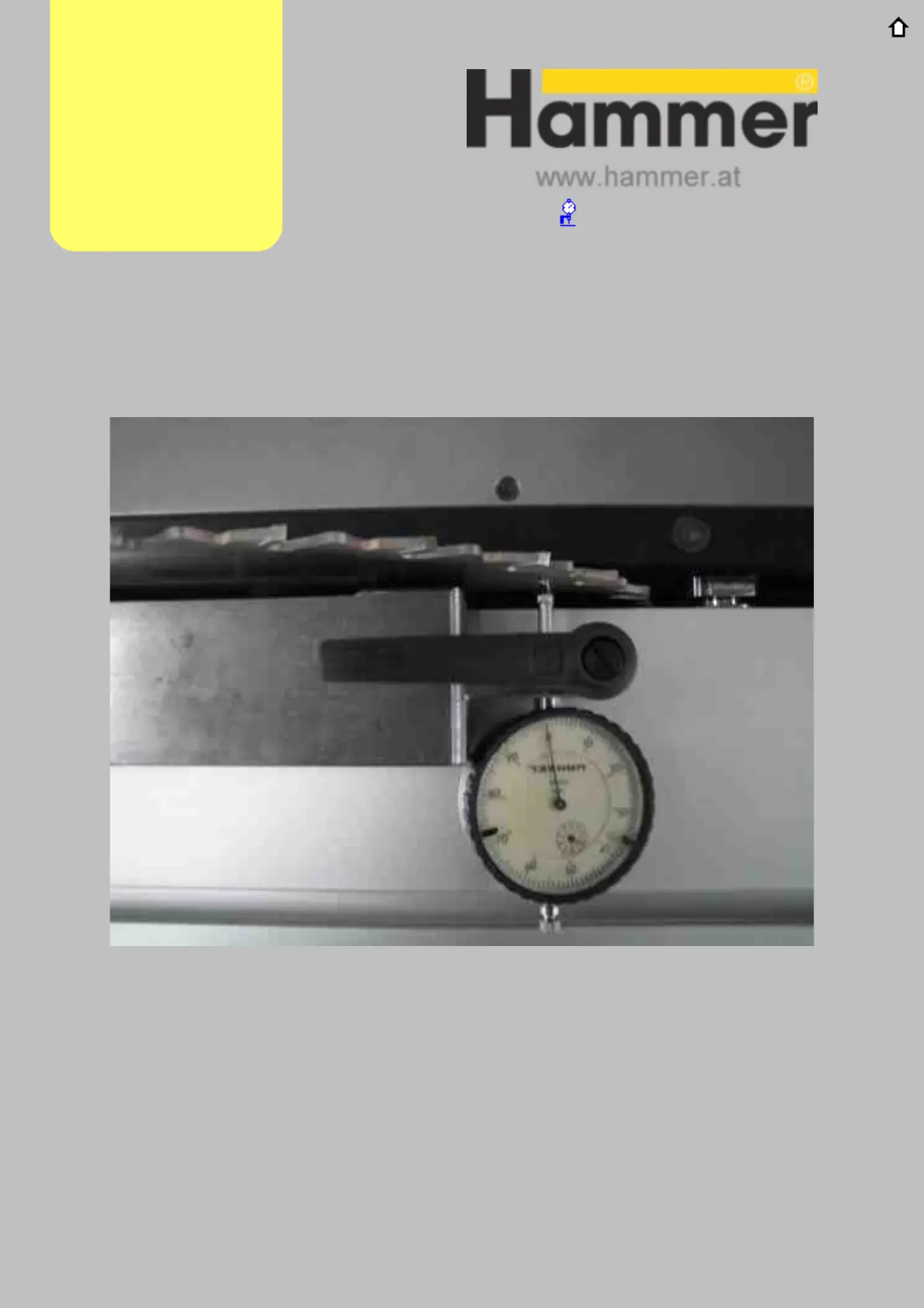

To measure the free-cut you will need a dial indicator. Place the indicator on the

sliding table, with the needle touching the saw blade at the front of the blade, but not

the teeth, as shown in figure SS01.1

Figure SS01.1 Start position of the dial indicator

Rotate the saw blade several times and find it’s lowest value. This effectively gives us

a reference point that we will be able to check at the other end of the blade. You can

zero this low-point on the scale or use arithmetic to calculate what the next reading

must be within. For a Ø300mm saw bl

ade, there should be between 0.05mm and

0.1mm of toe-out. (0.002”-0.004” Imperial).

Keeping the dial indicator perfectly stationary on the sliding table, move the sliding

table until the needle of the dial indicator is close to the back tooth of the saw blade,

shown in figure SS01.2. Now rotate the saw blade to find the same low point. This

low-point value subtracted from the previous value equals the current free-cut

amount (LET 0 = 1).

Adjustments

Alig nm e nt Lin k

Continued…

Loading...

Loading...