Page. 34

9

.䎃 Troubleshooting

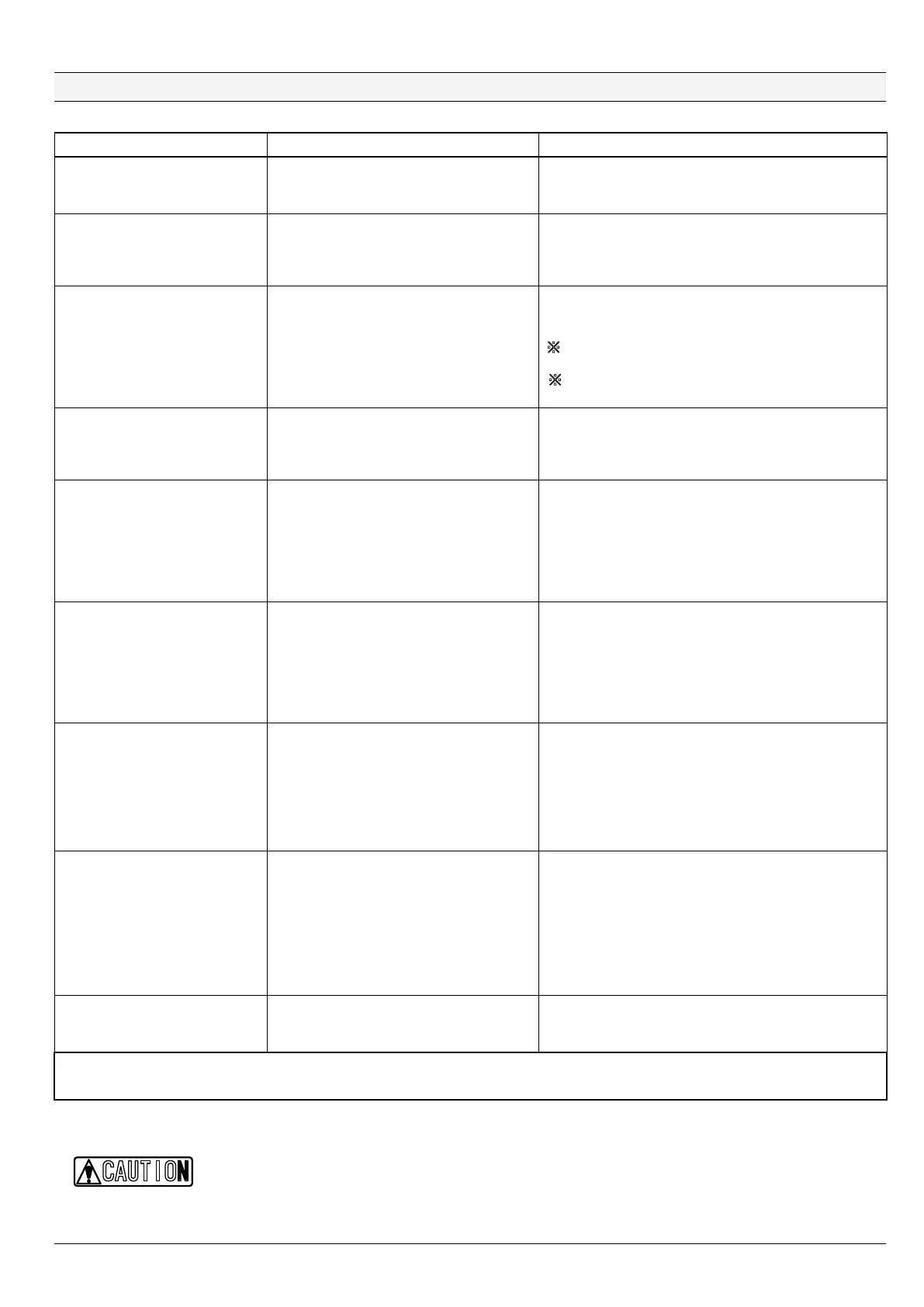

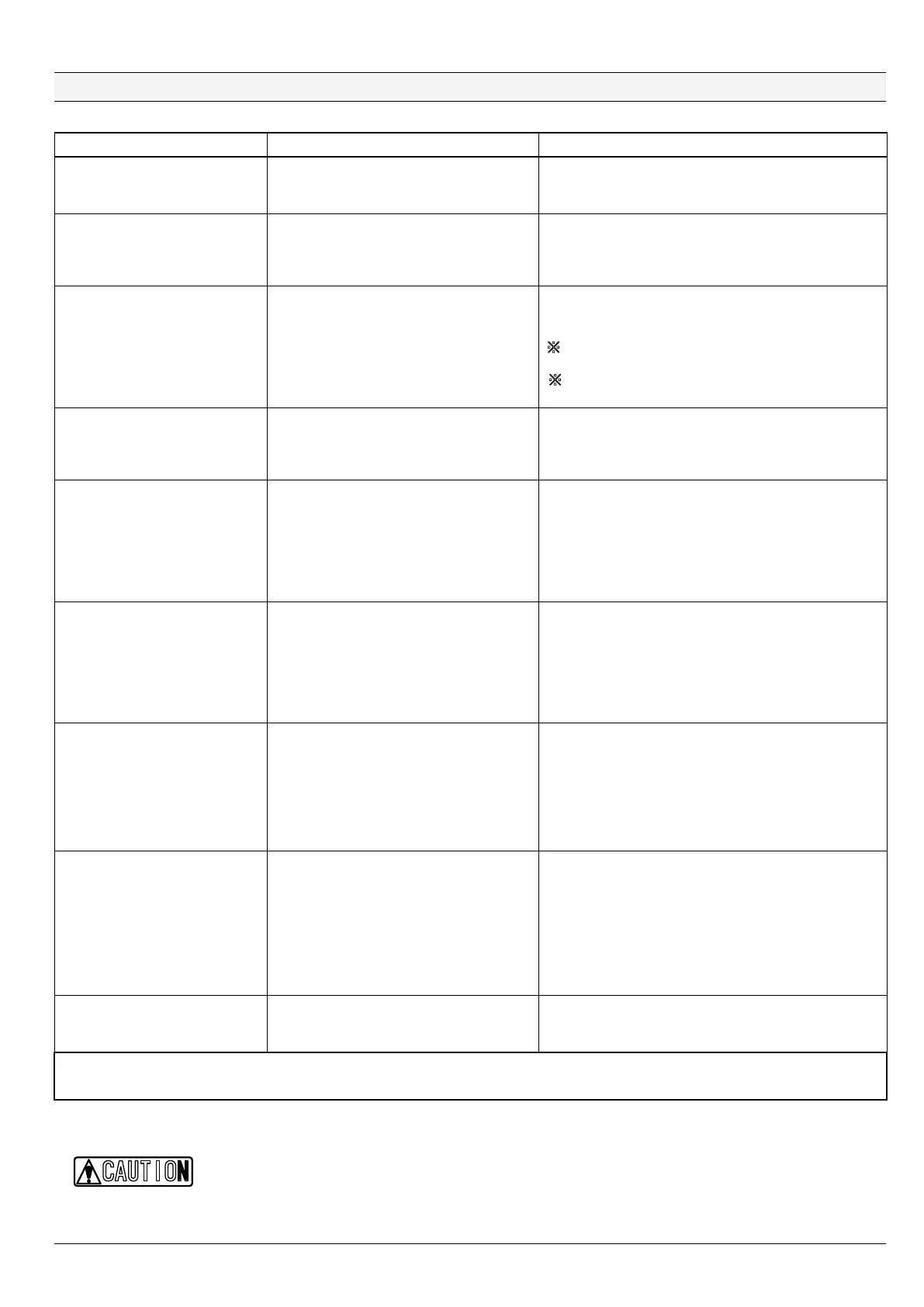

Ŷ Principal measures against failure

Symptom Possible cause Action / measures

No power supply Ɣ The oil concentration detector fuse was

blown out by an overvoltage on the oil

concentration detector.

Ɣ Check the supply voltage (90 to 240 V).

Turn off power to the oil concentration detector and

replace the fuse by a new one.

Inactive three-way valve Ɣ The three-way valve fuse was blown out

by an overload on the three-way valve

terminals.

Ɣ Check the cable between the oil concentration detector

and the three-way valve for short-circuit or damage.

Check the three-way valve for troubles. Replace the

fuse by a new one.

Asynchronous three-way valve and

Alarm1 operations

Ɣ An Alarm1 delay time has been set. Ɣ Check the setting data and ranges (see 6-2-1) and set

the Oil Alarm Delay 1 to "0 sec" (see "6-2-2. Setting

method").

䚚䎃

The Alarm1 output should work in synchronism with the

AL1 lamp.

䚚

You cannot set a delay for the three-way valve output

signal (VALVE).

Different Alarm1 and Alarm2

operations

Ɣ Oil alarm points and delay time set for

Alarm1 and Alarm are invalid.

Ɣ Correct the set values according to "6-2-2. Setting

method." To synchronize Alarm1 and Alarm2 operations,

the set values for Oil Alarm Points 1 and 2 of Oil Alarm

Delays 1 and 2 should be identical.

No alarm operation Ɣ The connection with the alarm panel and

cable connections may be wrong.

Ɣ The connected alarm panel may be

defective.

Ɣ The Alarm1/Alarm2 relay malfunctions.

Ɣ Check the cable connection. When the cable

connection is right, check cables for disconnection or

damage. Replace the cable if defective.

Ɣ Inspect the alarm panel.

Ɣ Check whether the terminal operation (output) of the oil

concentration detector is normal in the standby state

according to "7-1-6 Alarm Operation check."

Inactive measuring instrument

connected to the RECout terminal

Ɣ The connection of the measuring

instrument may be wrong or the

connection cable may be defective.

Ɣ The connected measuring instruments may

bedefective.

Ɣ RECout output failure

Ɣ Check the cable connection. When the cable

connection is right, check cables for disconnection or

damage. Replace the cable if defective.

Ɣ Inspect the connected measuring instruments.

Ɣ Check whether the terminal operation (output) of the oil

concentration detector is normal according to "7-1-4

RECout output check."

Inoperable switch Ɣ The operation switch malfunctions.䎃 Ɣ Check whether the switch button can be pressed.

The button may be locked by paint when the system is

installed and built. Remove paint if the button is locked

by paint and check whether the button is operable.䎃

䎃 Ɣ The oil concentration detector is frozen. Ɣ Press the RESET switch and make sure the clock ounts

up on the "Standby" screen. Then check whether the

button is operable.

No runnning

䎃

Ɣ The oil concentration detector is frozen. Ɣ Press the RESET switch and make sure the clock

counts up on the "Standby" screen. When the

pressure of water supplied from the bilge pump to the

sample water inlet becomes 0.03 MPa or higher, check

whether the oil concentration detector runs.

䎃 Ɣ The pressure may be low or the pressure

switch is disabled.

Ɣ When the pressure of water supplied from the bilge

pump to the sample water inlet becomes 0.03 MPa or

higher, check whether the oil concentration detector runs.

No clock count (in seconds) on the

LCD display screen䎃

Ɣ The oil concentration detector is frozen. Ɣ Press the RESET switch and make sure the clock

counts up on the "Standby" screen.

Ɣ When the oil concentration detector cannot be recovered by the above operations, call your local Fellow Kogyo distributor or Sales Division of

Fellow Kogyo.

%#76+10

In the maintenance works below, power to the oil concentration detector must be shut off to prevent electric shocks and

device failures.

Ɣ Demounting the operational log memory card, remounting the memory card, and replacing the clock backup battery.

(See "2-3-2 Terminal arrangement of terminal base and inside connection of FOCAS-2000.")

Ɣ Cleaning the sensor. (See "8-4 Cleaning the sensor (brush washing).")

Ɣ Cleaning the filter. (See "8-5 Cleaning the filter.")

Ɣ Replacing silica gel. (See directions attached to desiccant (silica gel) which is an optional parts.)

Ɣ Other works. (See the instruction sheets of the replacement parts if available.)

Loading...

Loading...