Do you have a question about the Flashforge Adventurer 5M Pro and is the answer not in the manual?

Critical warnings about printer operation, including hot components, moving parts, and entanglement hazards.

Essential reminder to complete all installation steps before powering on the printer.

Guidelines for maintaining a safe and hazard-free workspace around the printer.

Precautions for safe electrical connection, grounding, and avoiding electrical hazards.

Safety measures to protect the operator from injury during printer use.

Important operational tips, including maintenance, modifications, and general handling.

Specifications for ideal operating temperature, humidity, and required clearance around the printer.

Recommendations for filament types and best practices for filament storage to ensure print quality.

User rights, warranty information, and copyright notice pertaining to the user guide.

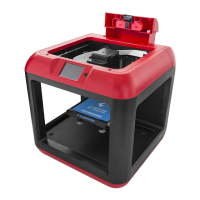

Identification and description of all physical parts and ports on the 3D printer.

Technical specifications and performance details of the Adventurer 5M Pro printer.

Step-by-step guide for safely unpacking the 3D printer and its accessories.

An inventory of all items included in the printer package for verification.

Instructions for attaching the filament spool holder to the printer body.

Procedure to remove the build plate locking screws before the first print.

Guide for initial setup, calibration, and running the first print job on the printer.

Introduction to recommended slicing software and essential pre-printing steps.

Detailed instructions for installing and operating the OrcaSlicer software for model preparation.

Guidance on installing and utilizing FlashPrint 5 for slicing models and preparing them for printing.

Procedures for loading new filament and switching filaments during the printing process.

Instructions for connecting the printer to a network via Wi-Fi or Ethernet.

Methods available for transferring print files, including USB and Wi-Fi transfer.

Guide to using cloud services for remote monitoring and management of print jobs.

How to connect and use the printer's built-in camera for monitoring prints.

Safe procedures for removing finished models from the build plate.

Explanation of how and when to perform automatic bed leveling and vibration compensation.

Details on the printer's air filtration system and its automatic selection based on material.

Configuration options for sound, filament detection, auto-shutdown, and firmware updates.

Tips for using and cleaning different build plates to ensure optimal print adhesion.

Guidelines for nozzle care, material compatibility, and cleaning to extend lifespan.

Routine maintenance tasks such as lubrication, filter replacement, and cleaning.

Answers to frequently asked questions covering printing problems, connectivity issues, and hardware troubleshooting.

Information on how to reach Flashforge customer support for technical assistance.

| Max. Bed Temperature | 100 °C |

|---|---|

| Filament Diameter | 1.75 mm |

| Technology | Fused Deposition Modeling (FDM) |

| Nozzle Diameter | 0.4 mm |

| Connectivity | USB, Wi-Fi |

| Supported Materials | PLA, PETG, TPU, PA, PC |

| Layer Resolution | 0.1-0.3 mm |

Loading...

Loading...