6600 – 6665 – 6700 – 6765

33

E

N

G

L

I

S

H

9 - TROUBLESHOOTING

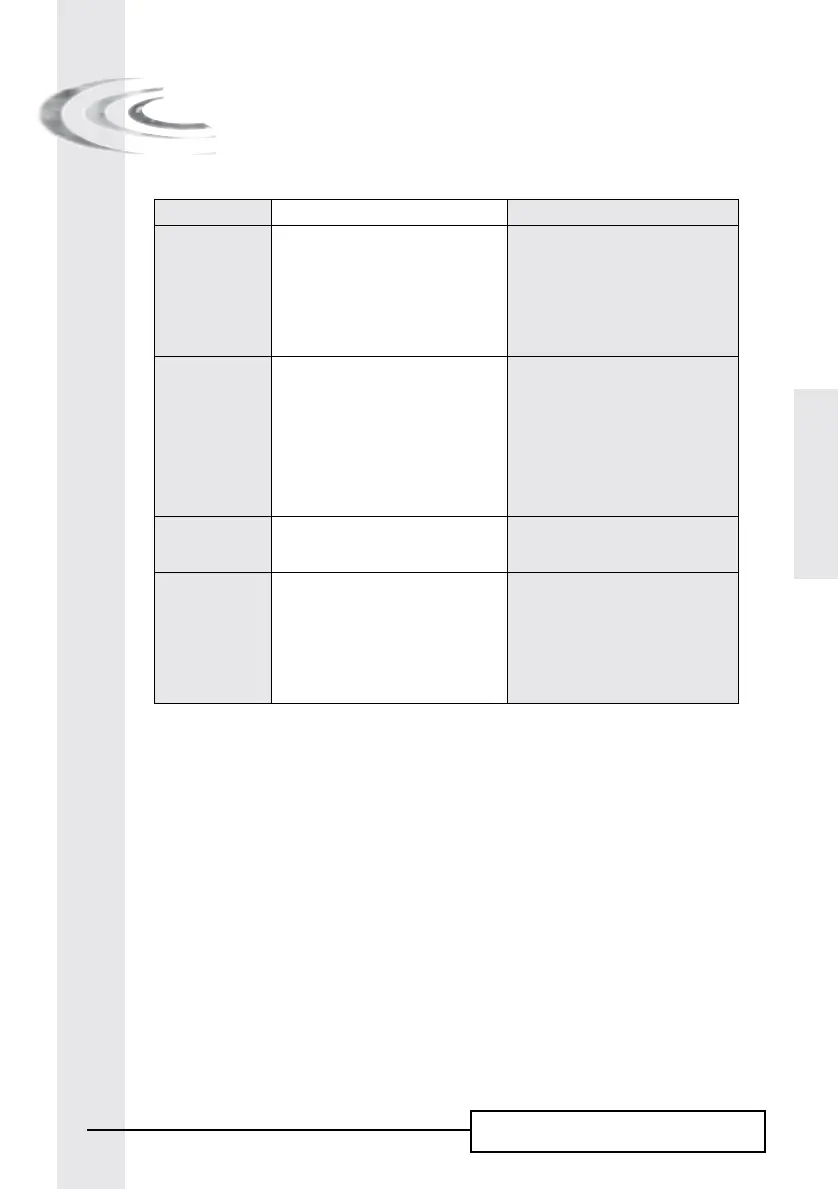

INCIDENT CAUSE SOLUTION

8. Salted water in in

service line

A. Filter and injector blocked

B. Power head not operating proper cycles

C. Foreign elements in brine valve

D. Foreign elements in the brine line flow

control (BLFC)

E. Low water pressure

F. Wrong programming

A. Clean injector and filter

B. Change power head

C. Change brine valve seat and clean it

D. Clean BLFC

E. Raise inlet pressure to 1,8 bar minimum

F. Check programming and modify if necessary

9. No brine draw A. Plugged drain line flow control (DLFC)

B. Plugged filter and injectors

C. Low water pressure

D. Internal valve leak

E. Wrong programming

F. Power head not operating properly

A. Clean drain line flow control

B. Clean filter and injector, change if

necessary

C. Increase inlet pressure to 1,8 bar minimum

D. Change seals, spacers and/or piston

assembly

E. Check programming and modify if neces-

sary

F. Change power head

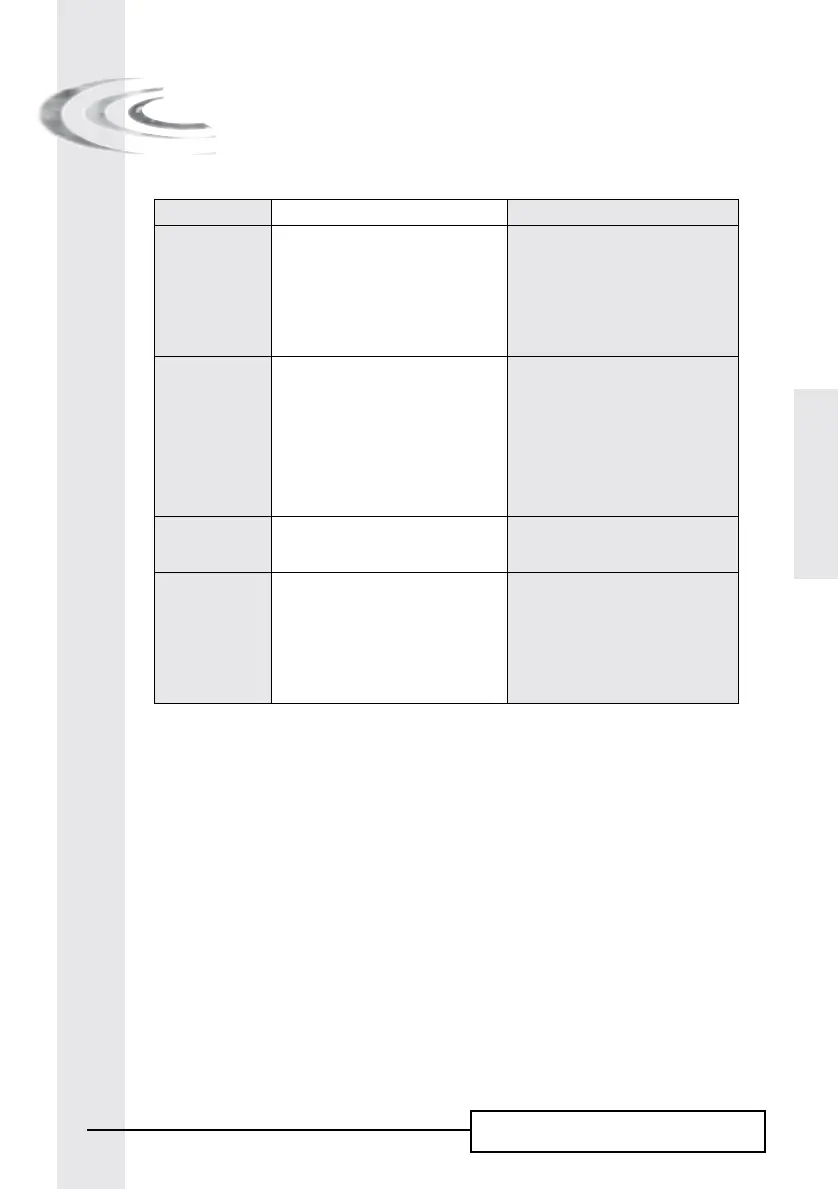

10. The valve regener-

ates constantly

A. Faulty power head

B. Faulty microswitch or wiring loom

C. Defective or badly set cycle cam

A. Change power head

B. Change microswitch or wiring loom

C. Reposition or change cycle cam

11. Constant leakage

to the drain

A. Foreign elements in the valve

B. Internal valve leak

C. Valve blocked in brine refill or backwash

D. Defective or blocked timer motor

E. Powerhead not operating properly

A. Clean valve and check it in the different

regeneration positions

B. Change seals & spacers and/or piston

assembly

C. Change seals & spacers and/or piston

assembly

D. Change motor and check gear teeth

E. Change power head

Loading...

Loading...