FT-13 Technical Manual, Rev. 1.40 March 2013

8.7 CANopen Option

Indicators which are equipped with the CANopen option can be connected to a PLC bus as described below.

Automatic (10 kbps to 12 Mbps)

Weight data will be updated each 40 ms

8.7.1 Electrical Connections

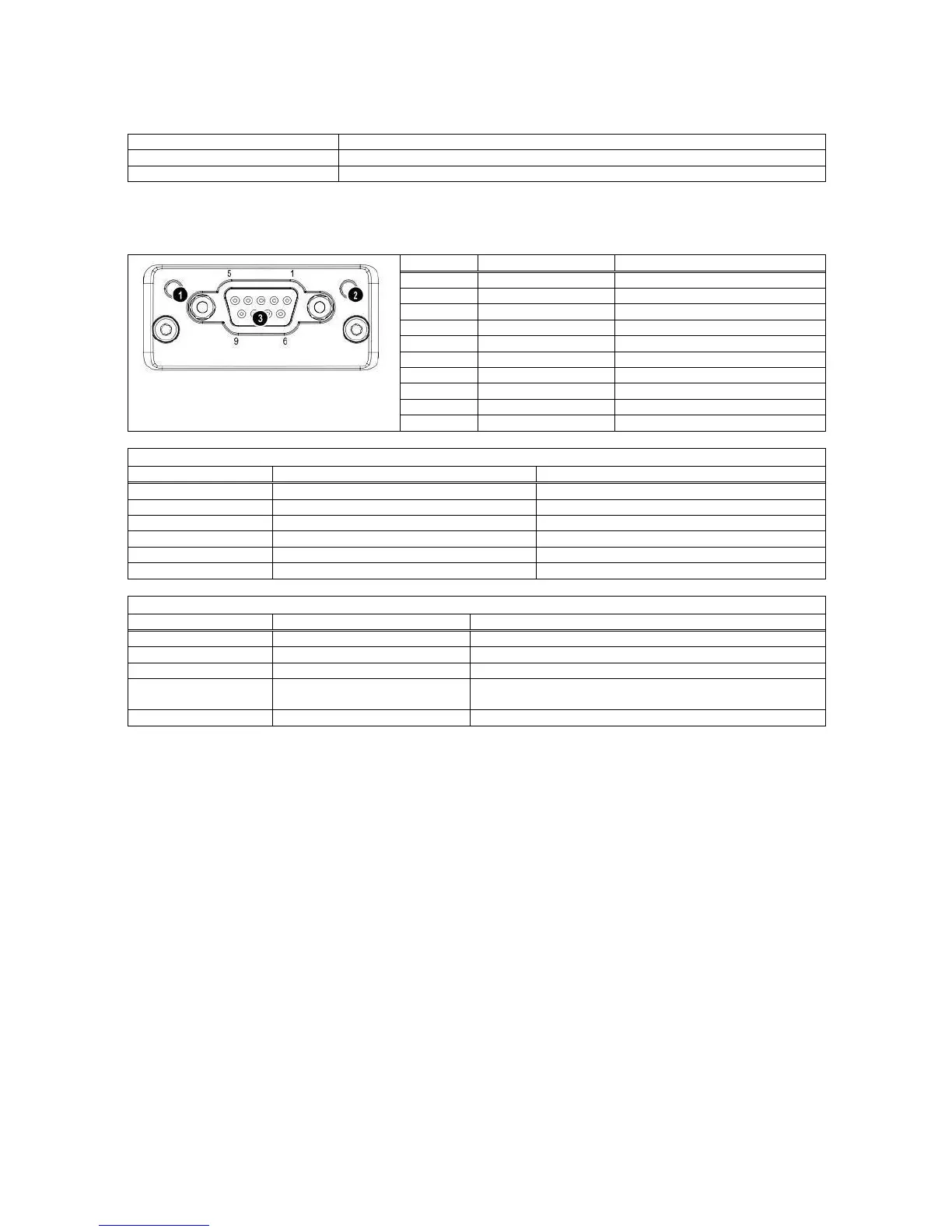

The pin configuration of the male 9-pol D-Sub ProfiNet connector (DB9M) is described in the table below:

1. Run LED

2. Error LED

3. CANopen Connector

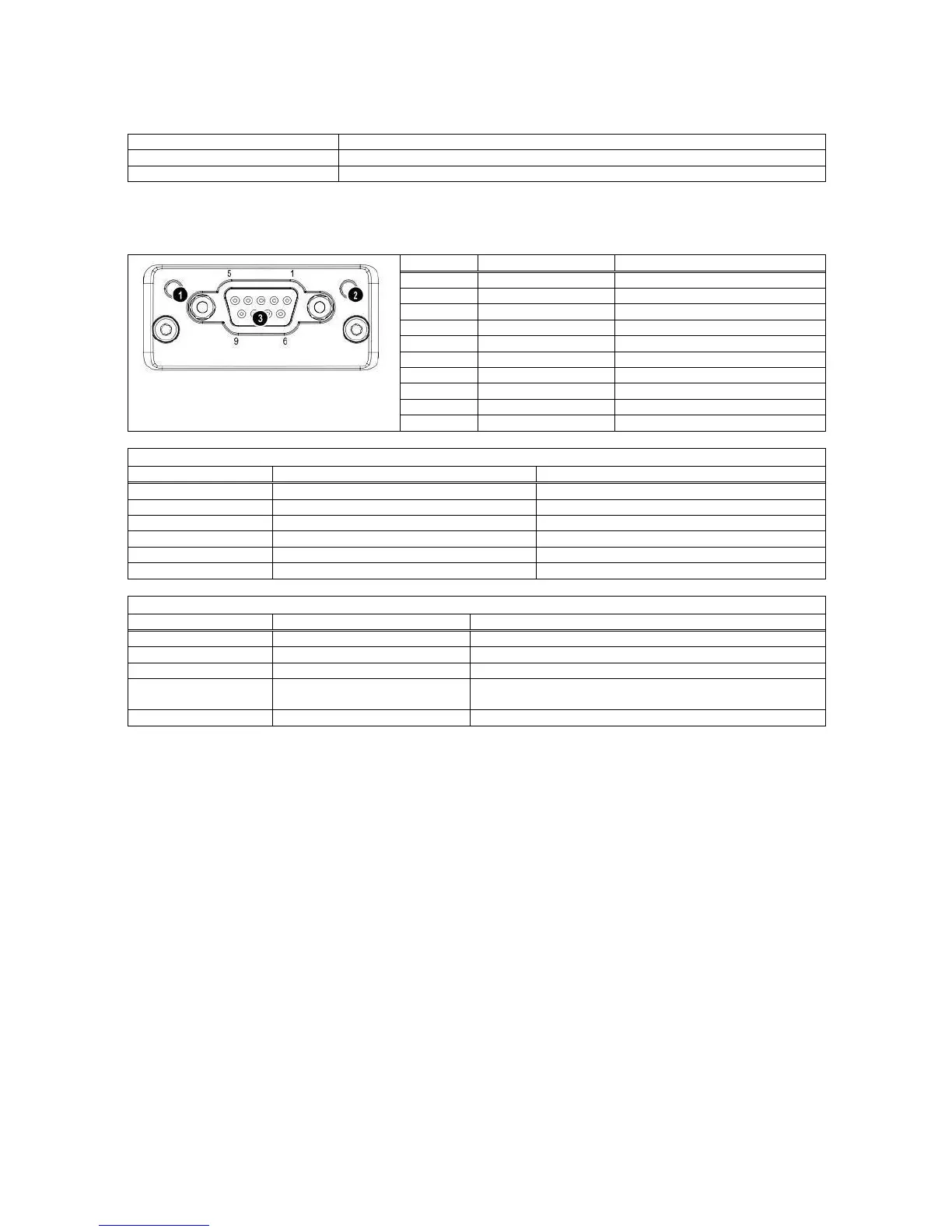

No power or not initialized

Check for hardware damages

Auto baud rate detection in progress

No power or CANopen module is inizializing

Bus error counter reached or exceeded its warning limit

A guard (NMT slave or master) or heartbeat event has

occured

8.7.2 Setup

[0--] Interface Block

[03-] CANopen

This sub-block includes the parameters of the CANopen.

[034 X ] Data Format

0 : Signed 32 bit integer

1 : Signed 32 bit floating point

[035 XX] Address

The address of the instrument will be entered via numerical keypad. Value range is 1 to 127. After editing

the address it is required to restart the instrument.

After the setup of these parameters and the hardware connection as described above, the data interface can

be used as described in Appendix 5.

Important hint: During the setup the CANopen output (weight value and status bits) will not be updated.

8.7.3 Data Structure

See Appendix 5.

Loading...

Loading...