Operating the Machine

46

14/03/2023 212601

6.5 Tapping with Depth Adjustment

Tapping is carried out with a tap suitable for the pre-drilled hole. As soon as

the pre-set threading depth is reached, the direction of rotation of the spindle

automatically reverses so that the tap is move out of the cut thread.

Use safety goggles

Always wear the necessary goggles when working on and with the machine!

Warning

Danger due to fast rotation of the drill spindle.

Fast rotation of the drill spindle can result in hair or clothing being pulled in.

This can lead to serious injuries.

Therefore, during operation of the machine

It is mandatory to wear a hairnet for long hair or a suitable headgear

Never wear gloves, neckties, bracelets, finger rings, chains or other loose

clothing.

1. Carry out all necessary work to prepare the machine (see section 5 Before

using the machine, page 29).

Then the tap is clamped and the machine set to the required height.

2. Clamp the workpiece in the mounted vise.

Attention

Danger due to repeated loads.

The repeated lifting of heavy weights can lead to unfavourable body loads and

rapid fatigue. When handling workpiece weights > 10 kg, use a suitable hoist

for loading and unloading operations.

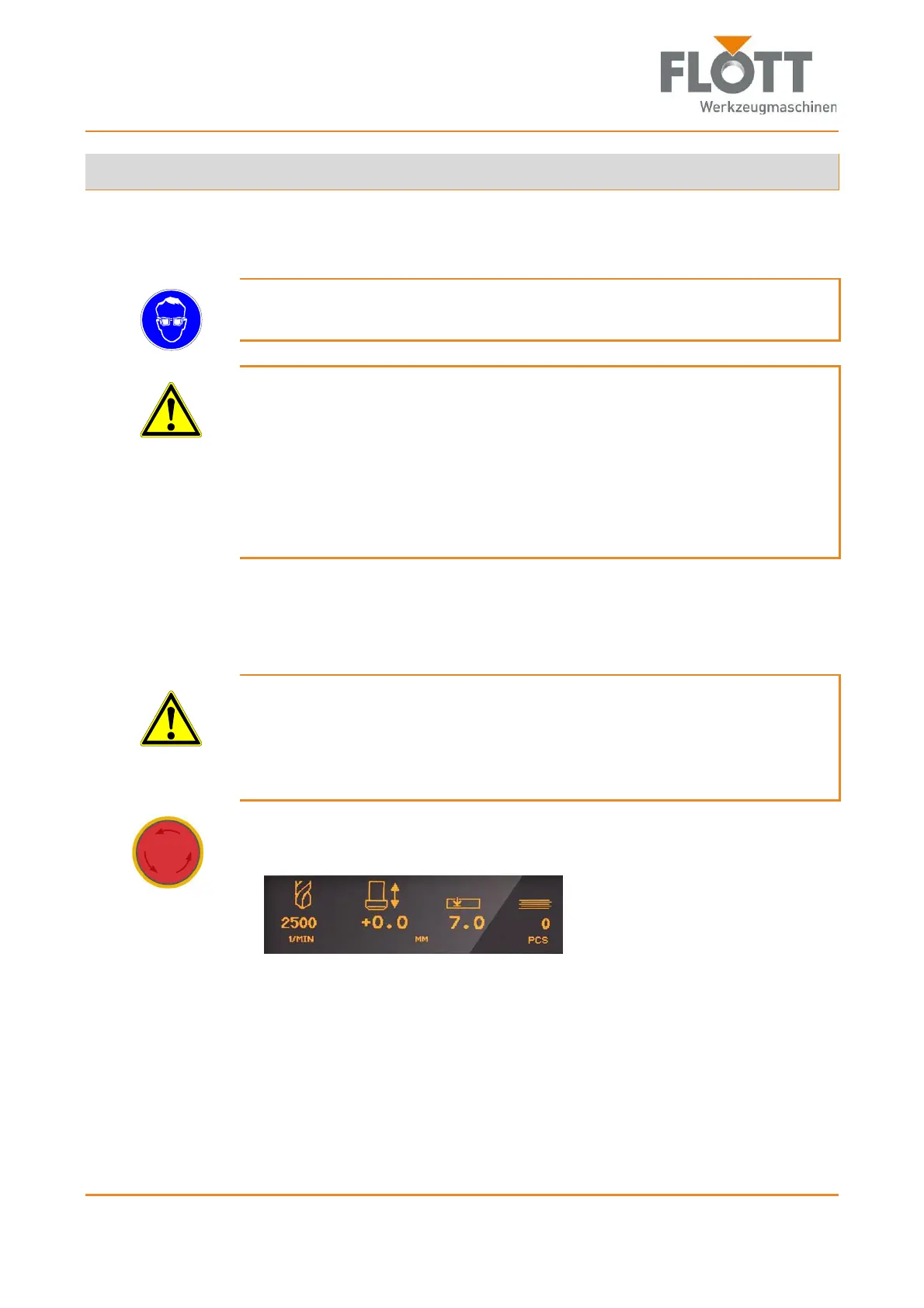

3. Unlock the emergency stop button.

Then the control system is restarted and the display appears:

After starting the control system, the drilling type Drilling shall always be

preselected.

Loading...

Loading...