10. Using a

5

16

in. open-end wrench, remove the inlet

screw from the face of the check valve body.

Remove the inlet check valve support and the inlet

poppet.

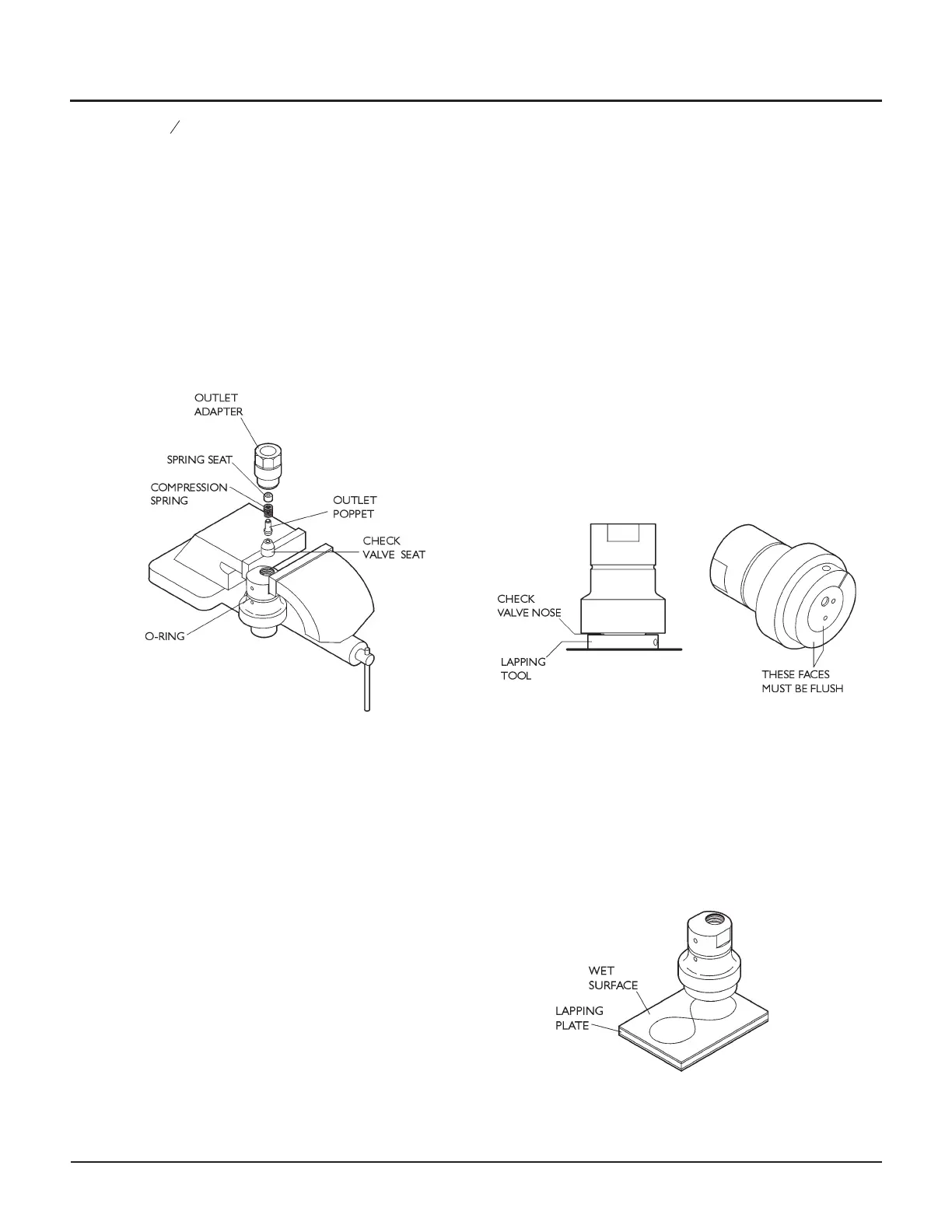

11. Clamp the check valve assembly in the soft-jawed

vise, holding the assembly on the flats of the check

valve body.

Remove the outlet adapter (loosened in an earlier

step) from the check valve body. Remove the out

-

let check valve poppet, compression spring, check

valve seat, and outlet spring seat and set aside.

Also remove the large o-ring from the check valve

body and set it aside.

12. Clean and inspect the check valve body and outlet

adapter.

Lapping the check valve body

Lapping notes

•

The dimensions for the check valve body listed at the

beginning of Maintenance Procedure D are the mini

-

mum allowed. You can re-use the check valve body

down to these dimensions, but you must discard the

check valve body if it becomes smaller.

•

Hand lapping, machining, machine grinding, polishing,

or a combination thereof are usually all acceptable

ways to remove surface imperfections from compo

-

nents before final lapping.

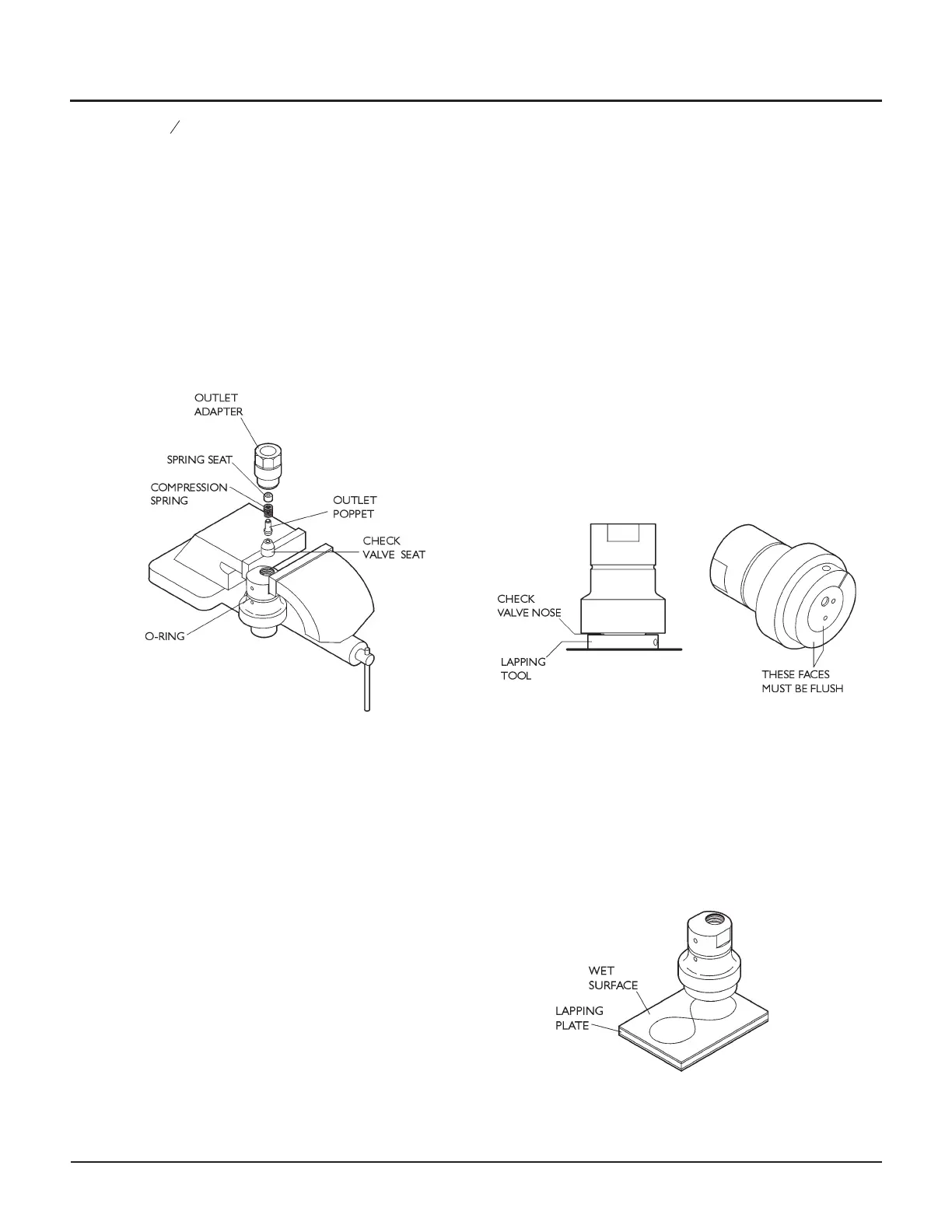

13. Install the check valve body lapping tool (014853-1)

around the check valve nose. Place the assembly, end

face down, on a flat surface. Slide the tool down as far

as it will go, until the check valve body and tool end

faces are flush. Tighten the lapping tool onto the check

valve body.

14. Attach a 320 grit abrasive strip to one side of the glass

plate, and a 600 grit strip to the other side.

Place a few drops of water on the 320 grit side of the

lapping plate. Lap the check valve body in a figure-8

pattern until all surface imperfections have been

removed.

© Flow International Corporation M-376 | 39

CHAPTER 3

Maintenance Procedures

Loading...

Loading...