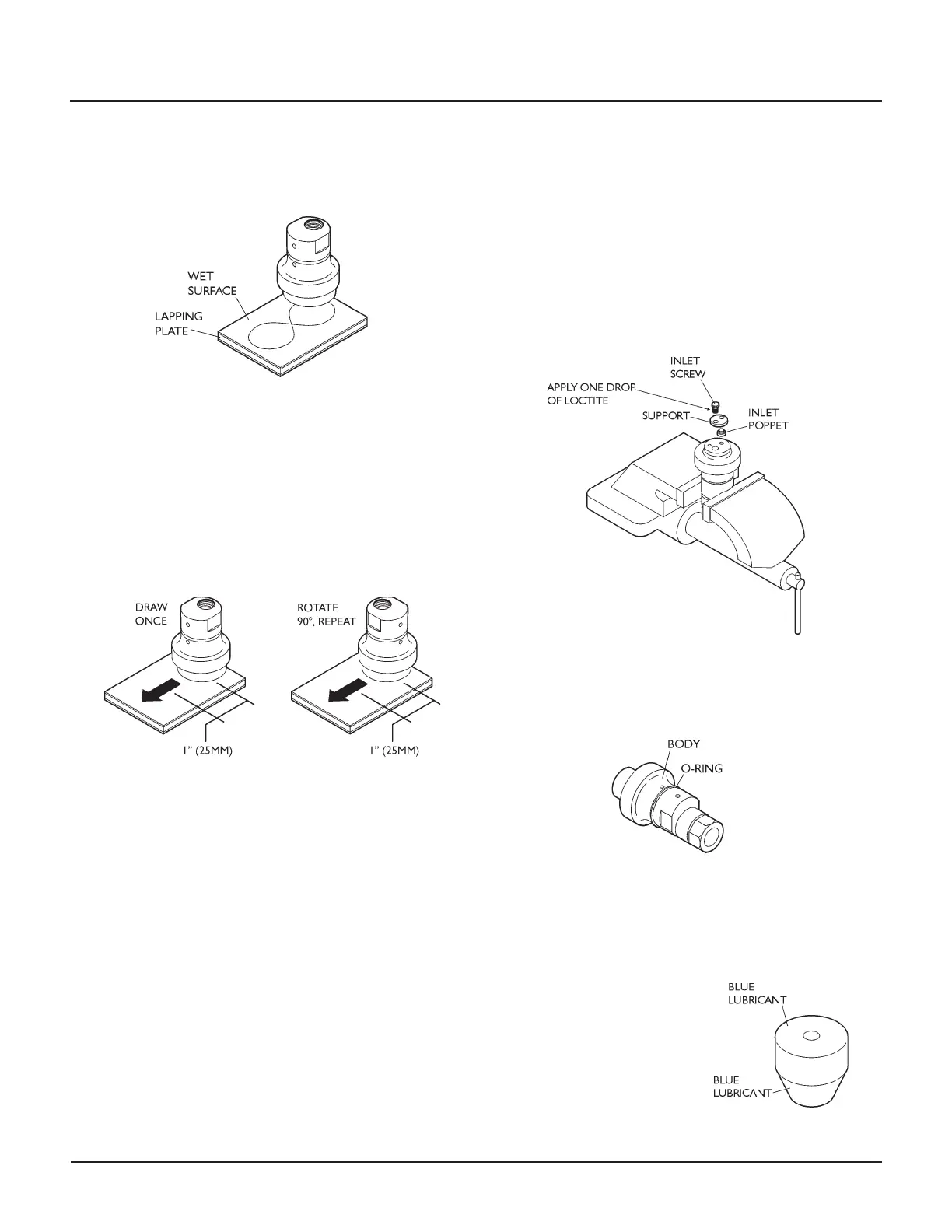

15. Turn the lapping plate over and place a few drops of

water on the 600 grit side of the plate. Lap the check

valve body in a figure-8 pattern until the body is

evenly polished.

16. To avoid poppet sticking problems, turn the lapping

plate back to the 320 grit side and draw the check

valve body for 1 in. (25 mm) in a straight line along

the abrasive strip once, then rotate the body 90° and

repeat the 1 in. (25 mm) score.

17. Carefully clean the newly-lapped check valve body

with clean solvent such as isopropyl alcohol. Dry and

re-inspect the part.

CAUTION

Lapping debris remaining after incomplete

cleaning will result in reduced component life.

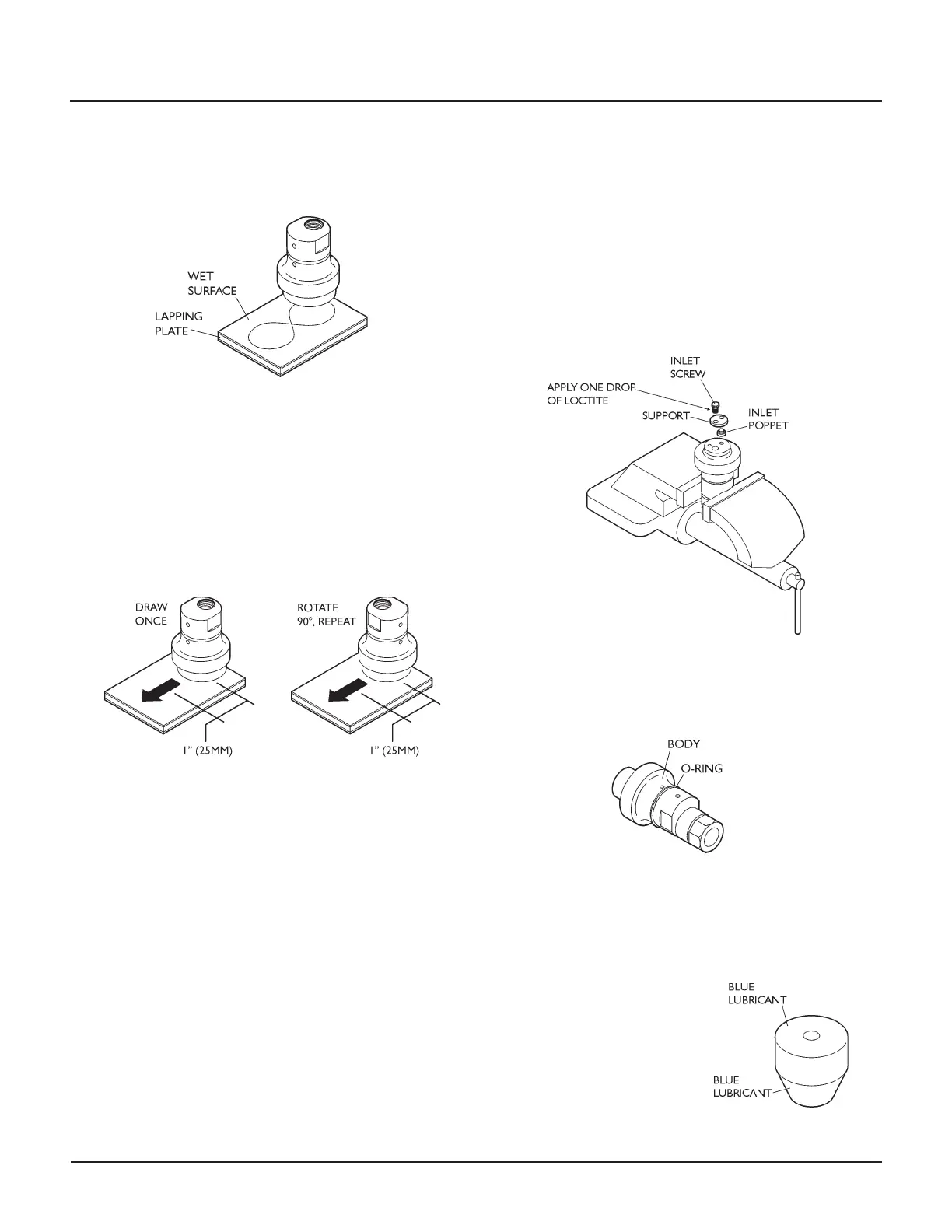

Installing the check valve inlet replacement kit

18. Set out and inspect the components of the check

valve inlet replacement kit (014884-1).

19. Apply one drop of Loctite #242 to the threads of the

new retainer screw. Position the new inlet check

valve support and new poppet on the main body,

with the pin of the inlet check valve support in its lo

-

cating hole.

Insert the retainer screw and tighten to 40 in-lb,

(4.52 N-m).

20. Lubricate the o-ring (removed from the check valve

body in Step 10) with food grade grease (A-4689).

Replace the o-ring on the check valve body.

21. Clean and inspect the outlet check valve seat, outlet

poppet, compression spring, outlet spring seat and

the threads and bore of the outlet adapter with sol

-

vent. See parts identified on the next page.

Apply a small amount

of Blue Lubricant to the

outlet adapter threads

and the conical surfaces

of the outlet check

valve seat.

40 | M-376 © Flow International Corporation

94K HYPERPRESSURE INTENSIFIER

Loading...

Loading...