covering flushing of driver bearings.

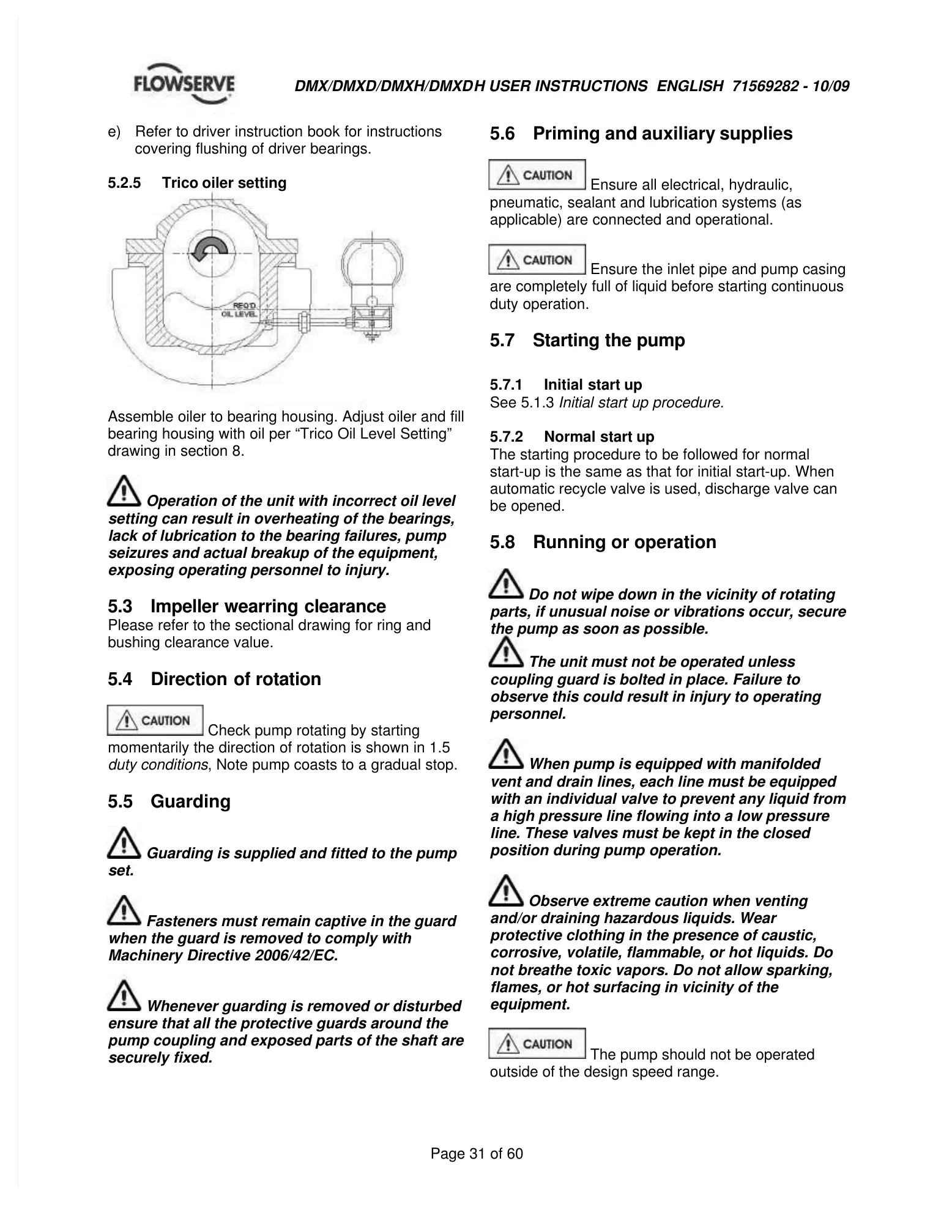

Assemble oiler to bearing housing. Adjust oiler and fill

bearing housing with oil per “Trico Oil Level Setting”

Operation of the unit with incorrect oil level

setting can result in overheating of the bearings,

lack of lubrication to the bearing failures, pump

seizures and actual breakup of the equipment,

exposing operating personnel to injury.

Please refer to the sectional drawing for ring and

Check pump rotating by starting

momentarily the direction of rotation is shown in 1.5

, Note pump coasts to a gradual stop.

Guarding is supplied and fitted to the pump

Fasteners must remain captive in the guard

when the guard is removed to comply with

Machinery Directive 2006/42/EC.

Whenever guarding is removed or disturbed

ensure that all the protective guards around the

pump coupling and exposed parts of the shaft are

Ensure all electrical, hydraulic,

pneumatic, sealant and lubrication systems (as

applicable) are connected and operational.

Ensure the inlet pipe and pump casing

are completely full of liquid before starting continuous

Initial start up procedure.

The starting procedure to be followed for normal

start-up is the same as that for initial start-up. When

automatic recycle valve is used, discharge valve can

Do not wipe down in the vicinity of rotating

parts, if unusual noise or vibrations occur, secure

the pump as soon as possible.

The unit must not be operated unless

coupling guard is bolted in place. Failure to

observe this could result in injury to operating

When pump is equipped with manifolded

vent and drain lines, each line must be equipped

with an individual valve to prevent any liquid from

a high pressure line flowing into a low pressure

line. These valves must be kept in the closed

position during pump operation.

Observe extreme caution when venting

and/or draining hazardous liquids. Wear

protective clothing in the presence of caustic,

corrosive, volatile, flammable, or hot liquids. Do

not breathe toxic vapors. Do not allow sparking,

flames, or hot surfacing in vicinity of the

The pump should not be operated

outside of the design speed range.

Loading...

Loading...