In case of double suction pump (DMXD and

DMXDH), remove crossover bushing [1600].

Crossover bushing is horizontally split and held

together by dowel pins [6810].

ring at each impeller. Channel rings are

horizontally split and are held together by

shoulder screws or dowel pins.

Channel rings are precision machined as a

set, after being dowelled. They should be match

marked and numbered for reassembly purposes. It is

suggested that the two halves be placed back

to back) impellers. Center bushing is horizontally

split and held together by socket head cap-

screws [6570] and dowel pins [6810].

sleeve has a shrunk fit to the shaft and will have

to be heated to remove. Heat throttling sleeves

O.D. evenly throughout its length to

outboard impeller [2200], split ring [2531] and

When heating parts, gloves or other suitable

After impeller is heated, it will have to be pushed

towards the center of the pump, the split rings [2531]

removed and quickly pulled from the end of the shaft.

The shaft is step machined at each impeller

fit to ease the disassembly process. It is

recommended that each impeller be marked with

stage number to insure proper reassembly.

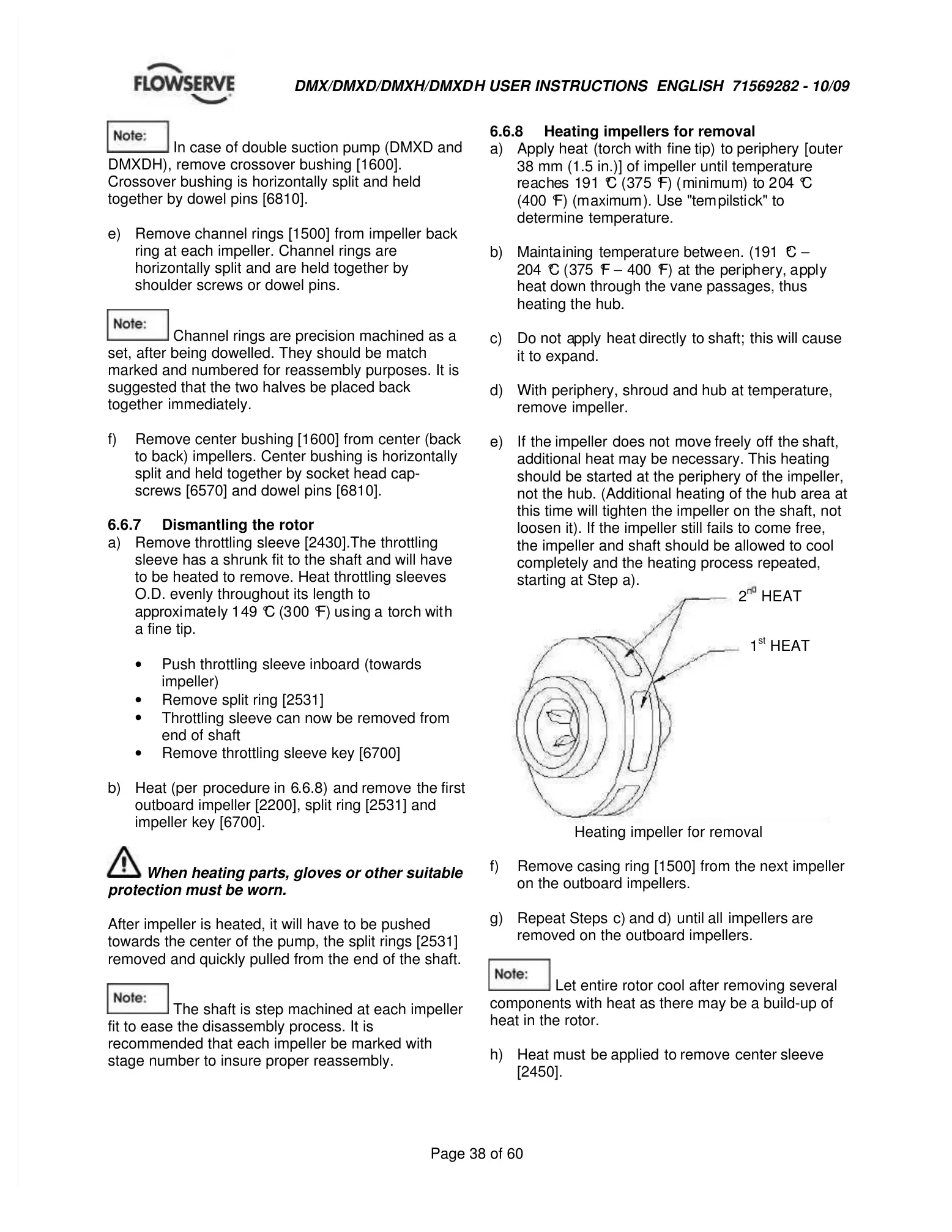

38 mm (1.5 in.)] of impeller until temperature

heat down through the vane passages, thus

additional heat may be necessary. This heating

should be started at the periphery of the impeller,

not the hub. (Additional heating of the hub area at

this time will tighten the impeller on the shaft, not

loosen it). If the impeller still fails to come free,

the impeller and shaft should be allowed to cool

completely and the heating process repeated,

Heating impeller for removal

on the outboard impellers.

removed on the outboard impellers.

Let entire rotor cool after removing several

components with heat as there may be a build-up of

Loading...

Loading...