37

Limitorque L120-85 Installation, Operation and Maintenance FCD LMENIM1202-03-A4 – 06/15

flowserve.com

Figure 21: Shimming parts and their order of assembly

#6-1 & 6-2

Shims

#6-1 & 6-2 Remaining Shims

#4-1 Handwheel

Bushing

#43 O-ring

(not shown)

#4-2 Handwheel

Spacer

#52 Handwheel

Shaft

Washer

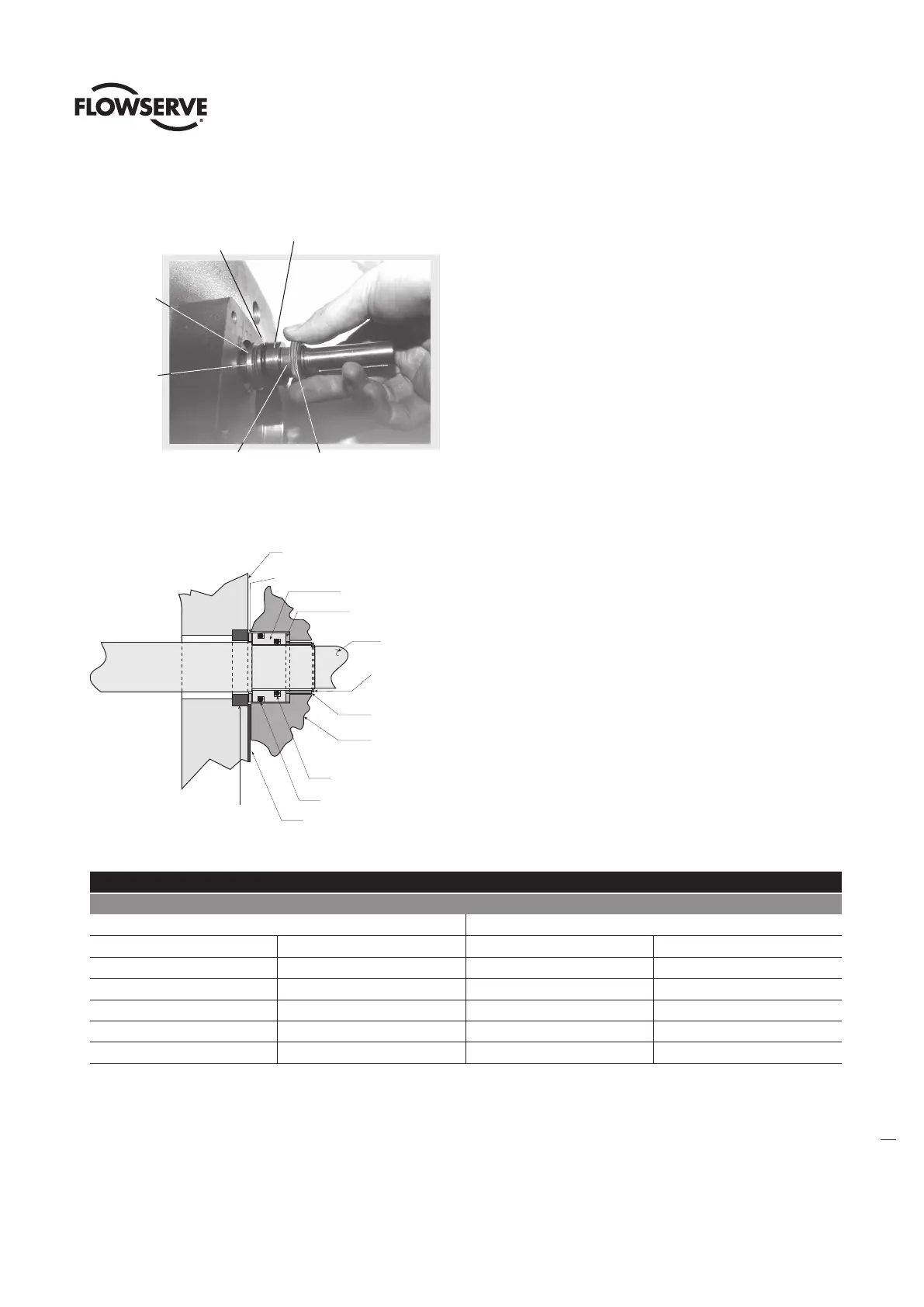

Figure 22: Shim location for gap “B” dimension

#5 Handwheel

End Cap

#42-4 Gasket

#4-1 Handwheel Bushing

#1 Housing face

(Handwheel end of actuator)

#4-2 Handwheel

Spacer

#Shims for

gap "B"

Shims for gap "A"

#4-3 Retaining Ring

#44 O-Ring

#43 O-Ring

#52 Handwheel

Shaft Washer

Table 5: Gap “B” shim thickness selection chart

Shim Thickness for Gap “B”

Shim Thickness

Used at gap “A” Required for gap “B”

.03" 0.76 mm .15" 3.81 mm

.06" 1.52 mm .12" 3.05 mm

.09" 2.29 mm .09" 2.29 mm

.12" 3.05 mm .06" 1.52 mm

.15" 3.81 mm .03" 0.76 mm

.18" 4.57 mm 0" 0 mm

10. Install Gasket (piece 42-4) and Handwheel End Cap (piece 5). Secure these pieces with four Hex Head Cap Screws (piece 50-3) and

Lockwashers (piece 50-4). Handwheel Shaft end play can be examined but is not required. According to dimensional tolerances, the

Handwheel end play with proper shimming techniques will be .000 to .034 inches (.00 mm to 0.86 mm).

11. When reassembling the thrust base, ensure EP-0 lithium base lubricant is replaced.

Loading...

Loading...