22

Installation and Operation Manual

• The display will flash “CONF” and “DUAL.T”

alternately.

• Press the DOWN button once. The display will now

flash “CONF” and “RSTART”.

• Press the left internal button once. This puts you

back into the operational mode.

• Replace internal button screws and o-rings.

CALIBRATION AND SETUP MODE

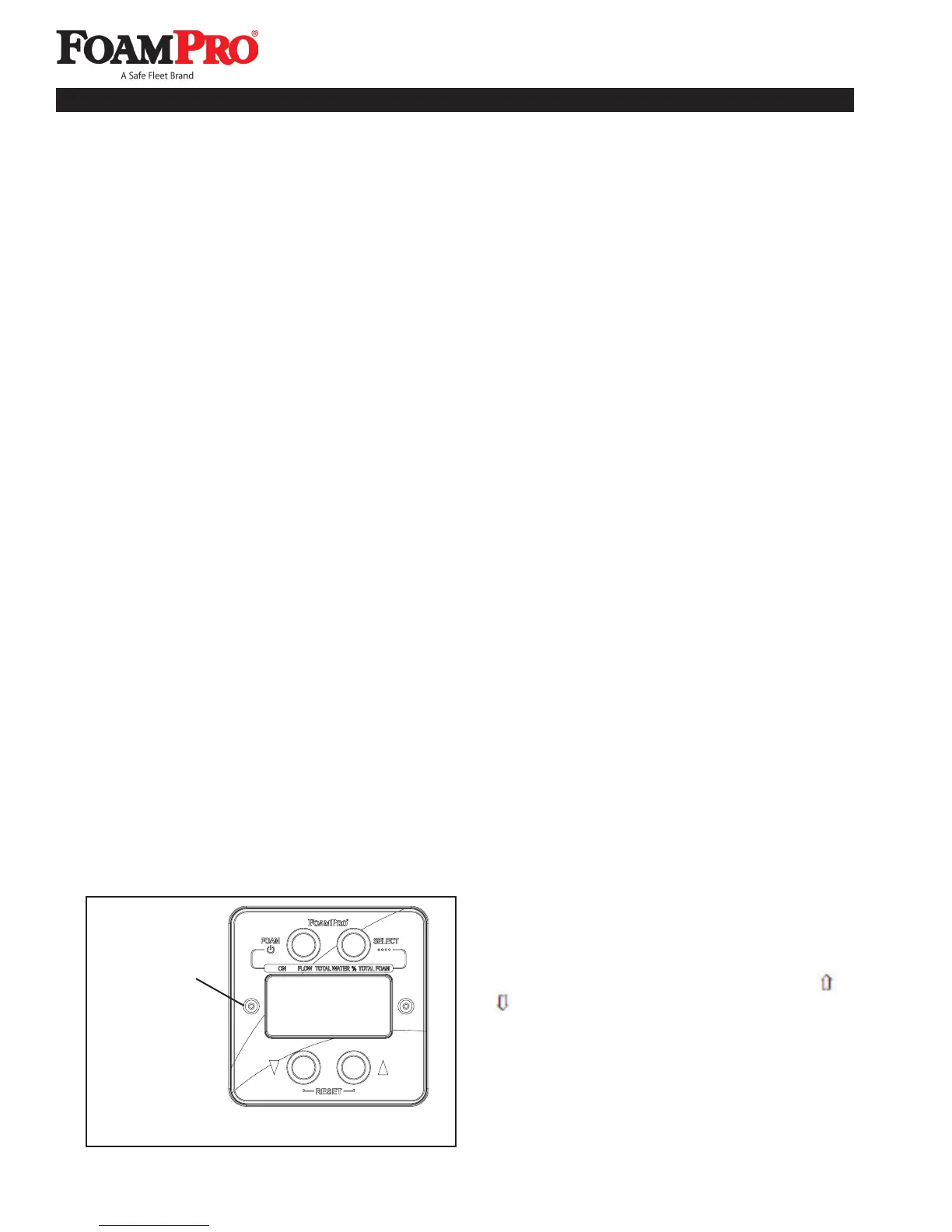

Calibration and Setup is done by using the Digital

Display Control Module function buttons. To enter or

exit the calibration and setup mode, remove the cover

screw and o-ring to the left of the display readout panel

on the Digital Display Control Module (See Figure 24).

Use a 3/32 inch Allen wrench to remove the screw and

also to operate the switch that is located beneath it.

To enter Calibration and Setup mode, use the Allen

wrench to depress and release the switch inside the

screw opening. The display will show “Elec Setup” until

any function button is pressed.

Exit from Calibration and Setup mode is accomplished

by pressing and releasing the switch again. “FRC or

HYPRO” will appear followed by a zero after several

seconds. REPLACE THE COVER SCREW AND

O-RING WHEN DONE.

CAUTION: Always replace the cover screw and

o-ring to keep water and dirt from entering the

digital display control module or serious damage to

the components may occur.

SYSTEM RESET

During calibration procedures, it may be necessary

to return the system to the original factory default

settings. To return to the factory default values, enter

calibration and setup mode as previously described.

Immediately after entry into calibration and setup mode,

prior to pressing any other button, depress the and

simultaneously. This action will return the system

to the factory default settings. Proceed with calibration

and setup after performing this reset.

NOTE: If using the Dual-Tank Option on the

controller and Reset is used, the Dual-Tank default

will need to be reconfigured.

Figure 24. Calibration Switch Location

Cover Screw to

be Removed

SYSTEM SETUP PROCEDURES

FoamPro systems permit easy calibration of the foam

proportioning unit to assure accurate operation. The

calibration process will make adjustments to the

flowmeter(s) and foam pump display readings.

NOTE: FoamPro systems can be calibrated to

any unit of measure, i.e. U.S., Metric, Imperial, etc.

It is necessary to use the same unit of measure

throughout the calibration process to ensure proper

proportioning by the system.

IMPORTANT: Both the foam pump and flowmeter

readings must be calibrated as a part of the initial

setup after installation.

Recalibration should only need to be done after major

repairs or changes to the foam system.

SETUP FOR DUAL-TANK OR REMOTE

START/STOP OPERATION

The FoamPro controller is factory defaulted to the dual-

tank option. If you are installing a remote start/stop

system, you must change the default setting for proper

system operation. The procedure for this new setting

starting from the operational mode is as follows:

• Remove the screws to enter the setup and

diagnostic modes.

• Enter the setup mode by pressing the internal

button on the left side of the controller.

• Enter the diagnostics mode by pressing the internal

button on the right side of the controller.

9 Calibration and Setup

Loading...

Loading...