31

Installation and Operation Manual

System 2000

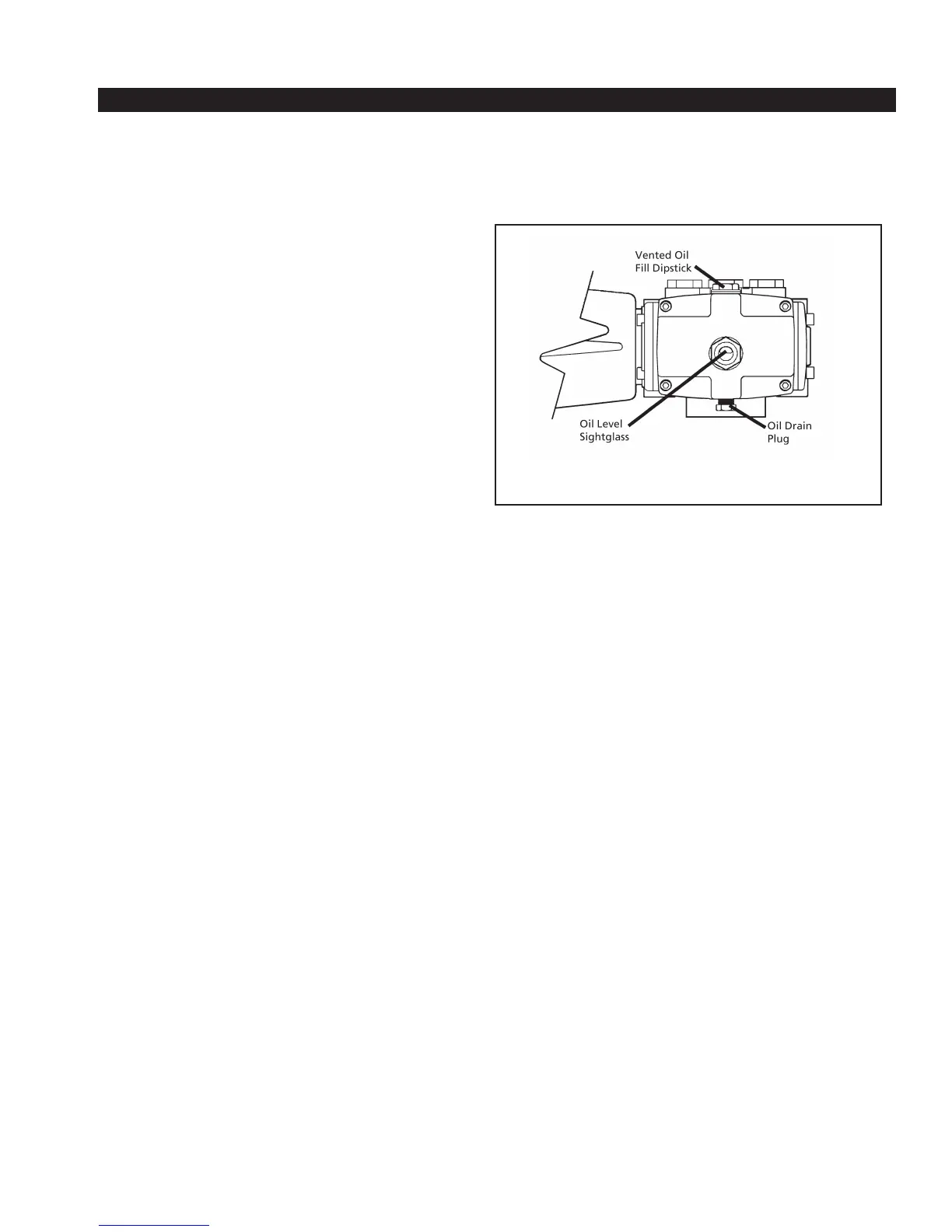

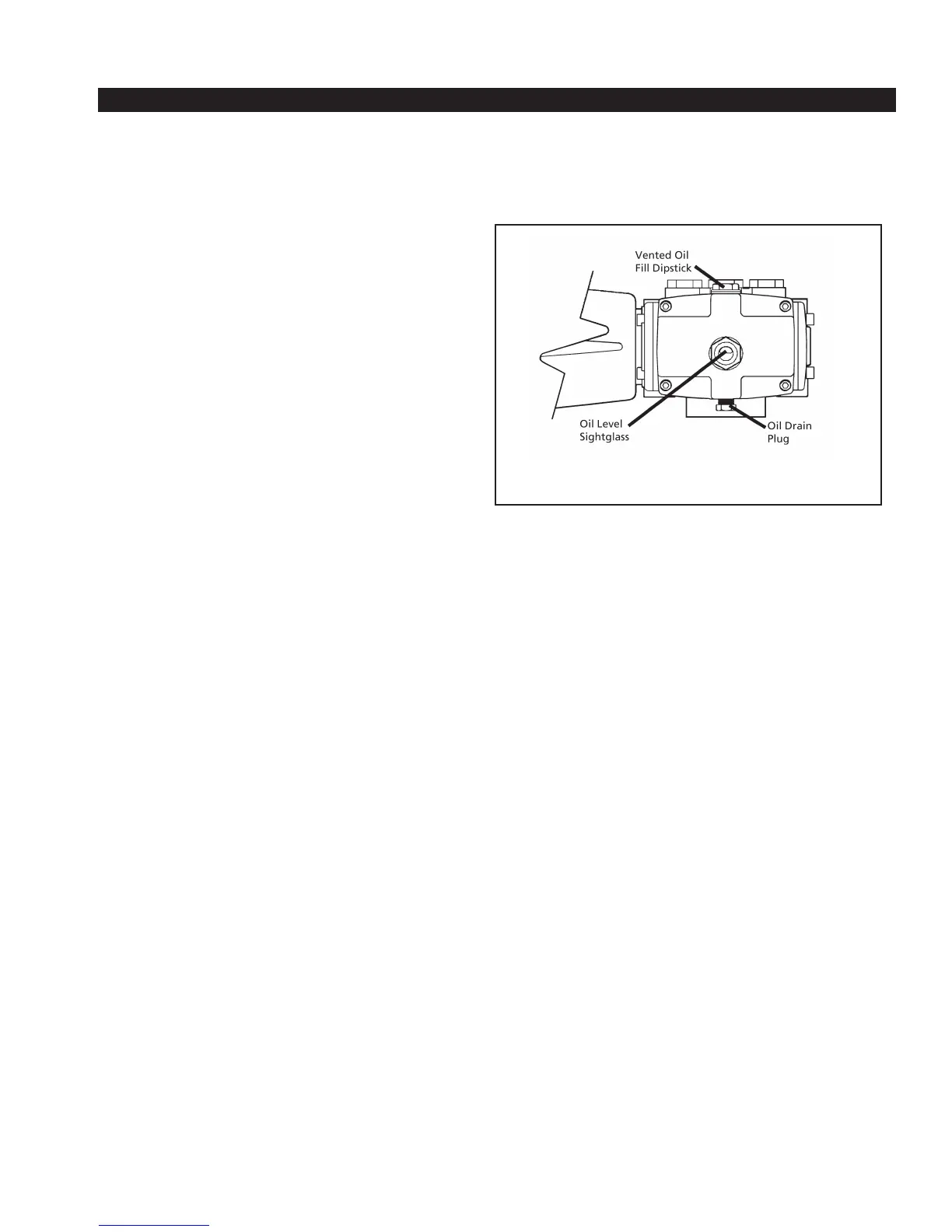

1. Monthly: Inspect wiring, hoses, flowmeters

and connections for tightness, corrosion, leaks

and/or damage.

2. Monthly: Remove and clean the foam strainer

screen(s). Flush as required.

3. Monthly: Check foam pump gear case oil level

and refill as necessary with proper lubricant as

described below.

4. Annually: Drain the pump oil and refill pump crankcase

with proper lubricant as described below. Check for

concentrate or water in the drain oil /ATF fluid.

Foam pump crankcase lubricant:

If your foam pump has regular oil in the crankcase,

replenish or change out with SAE 30 weight non-

detergent oil.

If your foam pump has an ATF fluid in the crankcase,

replenish or change out with a good quality Dextron II or

III ATF.

Do not mix fluid types in the crankcase or seal

damage may occur.

Note: Water quality, flushing and storage

techniques, environment and usage may have an

effect on your maintenance schedule. To ensure

equipment longevity, it is recommended to adjust

your schedule accordingly.

Caution: Release all pressure and drain all

concentrate and water from the discharge system

before servicing any of its component parts.

Figure 27. Foam Pump Oil Level Check

11 Maintenance

Winterizing

Flush out the pump with a RV & Marine antifreeze.

Then purge with air while running the foam pump.

Loading...

Loading...