34

Installation and Operation Manual

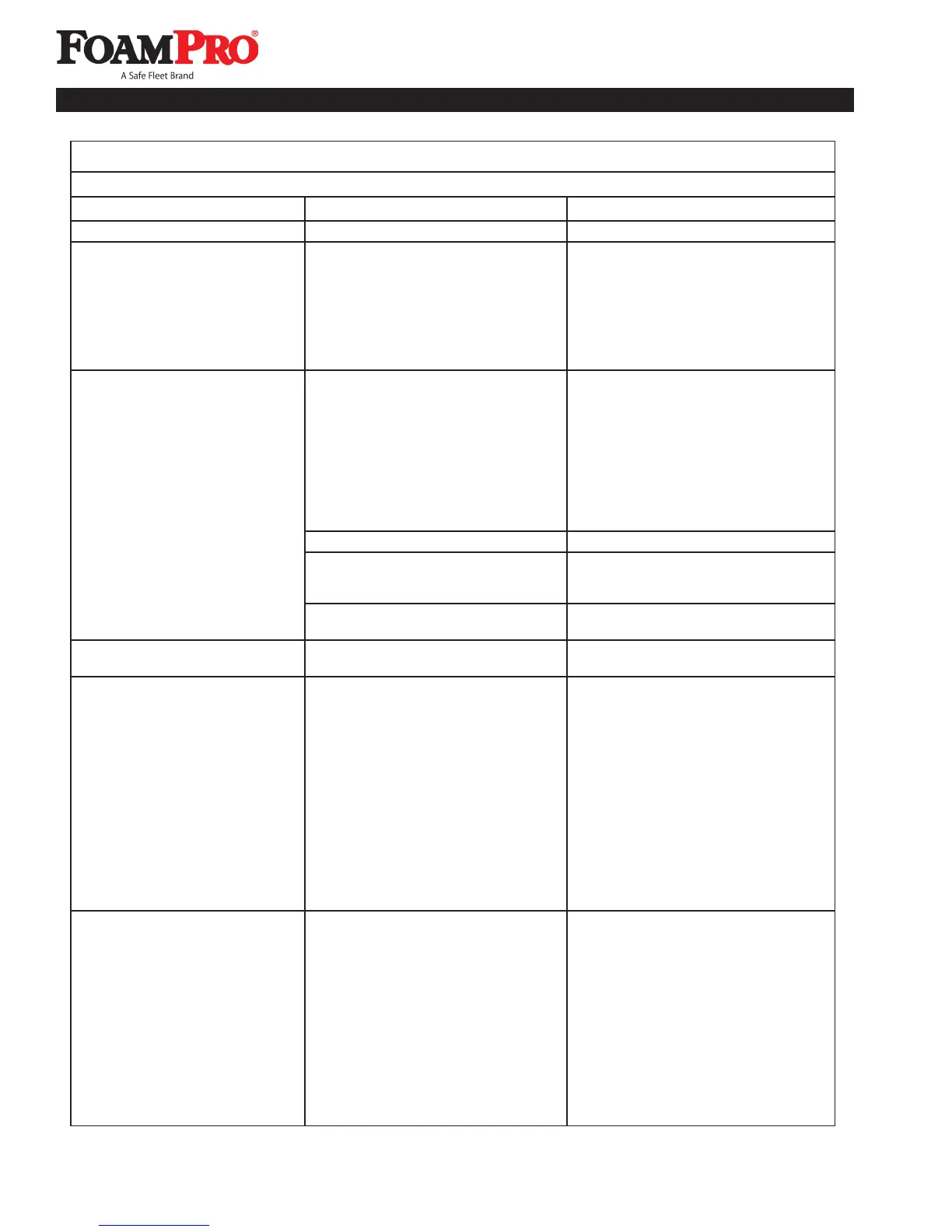

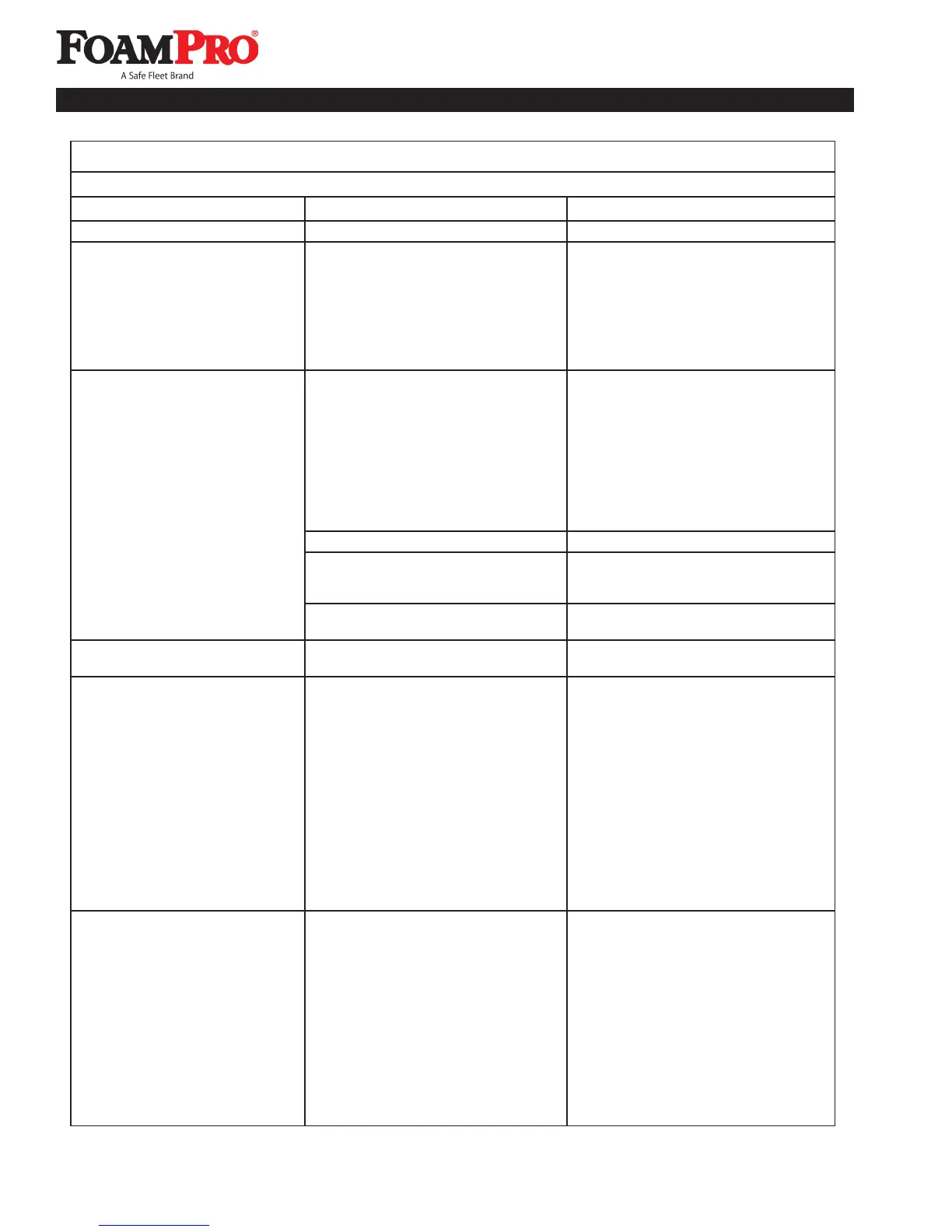

TROUBLESHOOTING GUIDE

Symptom Probable Cause(s) Corrective Action

Pump runs but produces no flow. Pump is not primed. See Foam Pump Priming Check section on Page 19.

Pump loses prime, chattering noise,

pressure fluctuates.

Air leak in suction hose or inlet fittings. Remove suction hose and test for leaks by pressurizing

hose with water. Make sure thread sealant has been

used on all fittings.

Suction line is blocked, collapsed or too small. Remove suction line and inspect it for a loose Iiner or

debris lodged in hose. Avoid all unnecessary bends. Do

not kink hose.

Clogged suction strainer. Clean strainer.

Pump runs for 8 to 10 seconds then shuts down.

ERR.EL may be flashed on display.

Inadequate voltage and/or ground Check connections and voltage readings

12+ volts for a 12 VDC system

24+ volts for a 24 VDC system

Check ground strap for clean connection to frame of

the apparatus.

Check for clean ground from apparatus frame to

battery ground.

Run diagnostics as described in Section 12 and recheck

voltage readings while running.

Speed Sensor circuit open Inspect wiring and connections to speed sensor.

Speed Sensor position incorrect Run diagnostics on speed sensor for proper readings.

If pulses are erratic, readjust sensor (from contact with

gear, back off 1/4 turn and lock in place).

Speed Sensor not functioning Run diagnostics on speed sensor. If pulses are still at "0"

replace sensor.

Pump runs full speed whenever the circuit

breaker switch is in “ON”.

Poor ground to motor driver box on pump/motor bracket. Make sure screws are tight and a good ground is

maintained.

No characters are displayed on the digital display. Note: The main switch is current limited to 41 amps

for System 2001/12V DC;

60 amps for System 2002 & 2002HP/12V DC;

22 amps for System 2001/24V DC;

30 amps for System 2002/24V DC;

60 amps for System 2024/24V DC

The main power switch is not “ON”. Turn on the main power switch on the computer

control module.

Cables not correctly connected. Inspect and secure connections.

Control cable(s) faulty. Replace control cable(s).

Digital display has been damaged. Replace the digital display.

Inadequate ground or voltage. Inspect connections & check voltage.

System is powered up and the Foam ON/OFF

switch has been pressed but the foam pump

doesn’t run.

No water is flowing in any of the foam discharges. Flow water.

Flowmeter wiring not correct. Inspect wiring and connection to flowmeter.

Flowmeter obstructed. Clear flow meter of debris.

Flowmeter not functioning. Replace flowmeter.

Float is on plunger wrong – indicating tank is low. Remove the snap ring at the top of the plunger and

remove the float, turn it over and reinstall.

Float stuck on plunger – indicating tank is low. Inspect and clean float switch.

Control cable(s) faulty. Check connections and replace control cable(s).

Loading...

Loading...