8

Installation and Operation ManualInstallation and Operation Manual

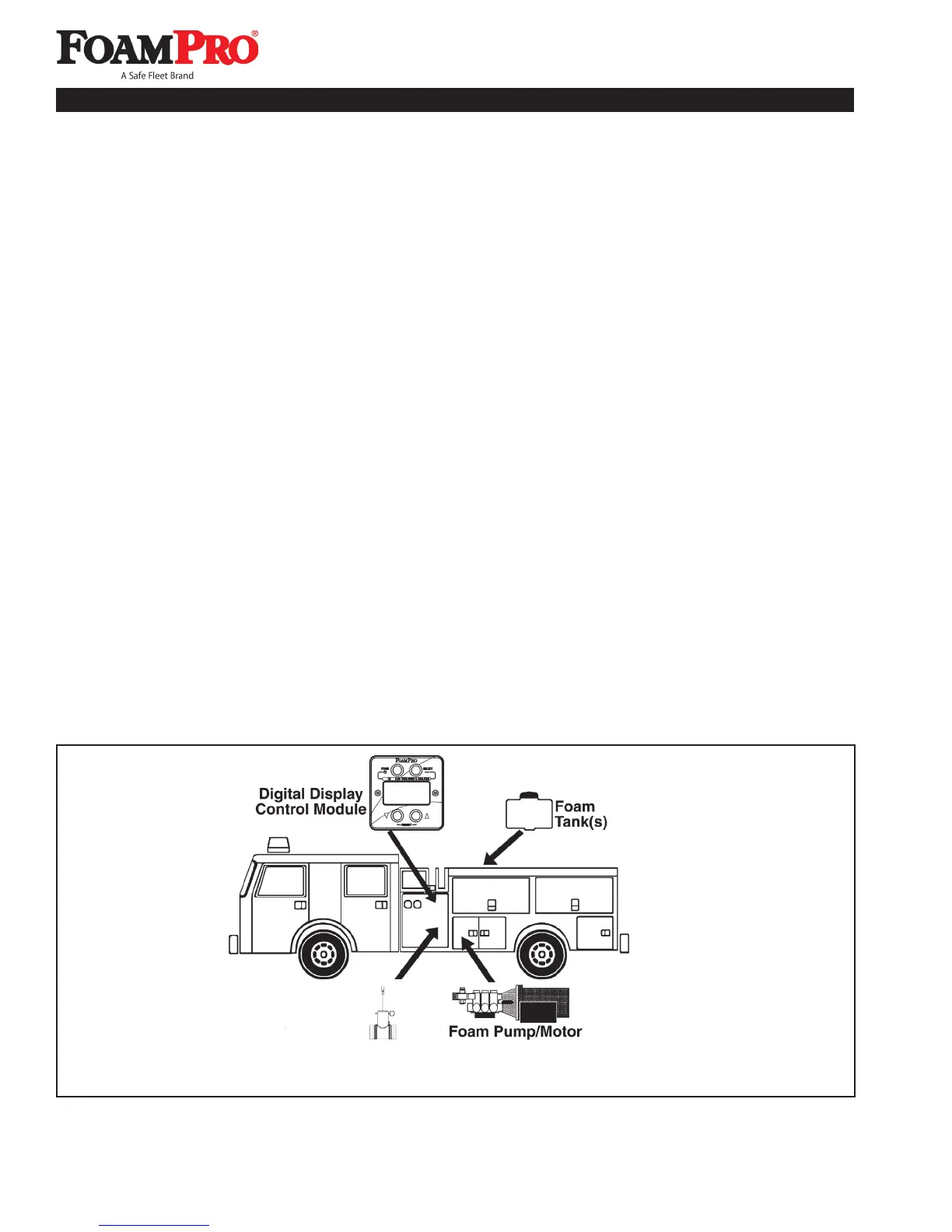

Because of the potential differences in apparatus

plumbing and foam system configuration, it is not

practical to depict exactly how each FoamPro unit can

best be installed onto a particular apparatus. Figure

2 shows the relative location of the FoamPro system

components. Most of the information contained in the

following sections, however, will apply to any situation.

It is recommended that you read the following

sections thoroughly before beginning installation of

the FoamPro system. It is also recommended that

you spend time planning and designing where and

how you intend to install this unit in the apparatus

before beginning the actual installation.

Determine the locations of the components to

be installed such as; foam tank(s), foam pump and

flowmeters. Try to place components in locations that

require the least amount of hoses and fittings.

Locate the foam pump unit in an area that is protected from

road debris and excessive heat buildup. Since the power

switch and CAL/INJECT valve are located on this unit, the

foam pump unit should be installed in an accessible area

located in the vicinity of the operator's panel.

Figure 2. System Component Location

The foam pump unit should be located below the

discharge of the foam tank(s) to provide for gravity feed

to the foam pump. The 2002 and 2024 systems can

be positioned with a suction lift not to exceed 6 ft (1.8

meters) and may be positioned accordingly. Locate the

foam tank(s) where the refilling can be done with 5 gallon

(19 liter) containers and other methods suitable to the

end user. Most water tank manufacturers will build the

foam tank(s) into the booster tank. When specifying

integral foam tank(s), make provisions for installing the

low-level sensor as well as foam suction connections

and tank drainage.

Determine a location for the Digital Display Control

Module on the operator panel of the apparatus.

Consider the routing path for the control cables from the

Digital Display Control Module to the foam pump unit

and flowmeter(s). If necessary, order longer or shorter

cable assemblies to suit the location demands.

CAUTION: Never attempt to cut or lengthen the

molded cables.

5 Installation Planning

HYPRO

Flowmeter

Loading...

Loading...