30

Operating Procedures - Quick start guide

The following section explains the 508DT vacuum forming process:

• Pull the Heater forwards over the clamped plastic.

• As the plastic heats up it may begin to rise slightly. It will then soften and begin to drop back.

• When performing an initial forming it will be necessary to check the progress of heating as this will vary

with plastic type, thickness and colour. Push the heater back slightly to test the softness of the plastic

manually or to observe its state. Continue heating until it is soft enough to form. When the plastic softness is

correct push the heater fully back.

• Lift the table until it is fully raised. Then press the VACUUM button to latch on the vacuum. The

moulding will form around the tooling.

• Once the plastic has cooled sufficiently the RELEASE button may be pressed to blow the moulding off

the mould. Too long or too soon a release may distort the moulding.

• Once released the moulding is now complete and the table may be lowered. Ensure the table has reached

its lower position. Release the clamp frame to remove the moulding for inspection.

• Review the results and determine the parameters required to produce the forming. @Use the save settings

feature to set and record the values for later recall.

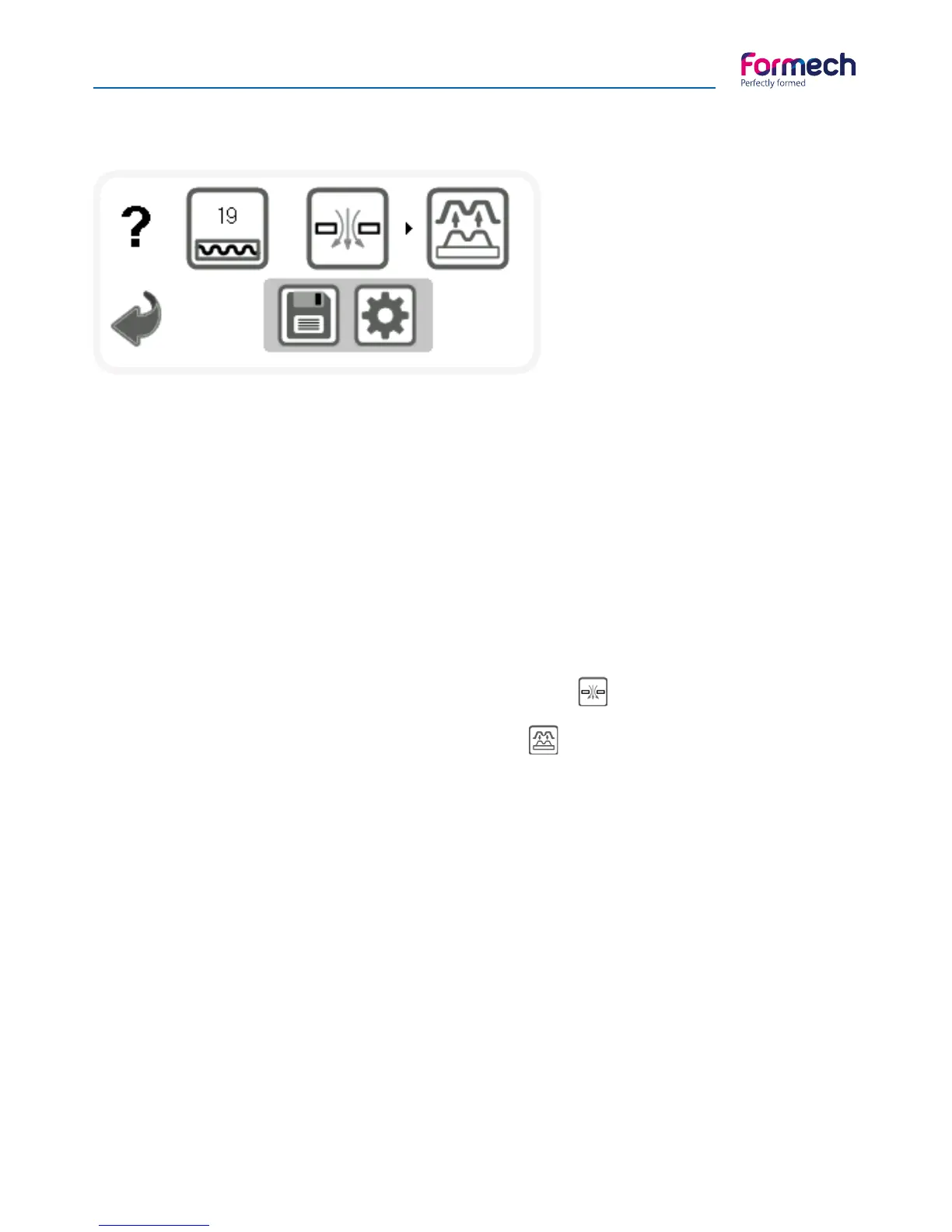

The 508DT Manual operation screen will

open as shown.

The Heater timer value on the HEATER

button will count UP when the heater is

pulled forwards and stop when pushed

back. The Vacuum button will latch the

vacuum ON when pressed. The Release

button will momentarily activate the

pump pressure when pressed.

Heater settings may be changes via the settings button. In manual mode the heaters are set to the default

values. The Save button will use the settings of the timers shown and import them to the settings screen to

edit and save as required.

508DT Basic operation

Loading...

Loading...