38

Tools

NOTES:

Porous mould materials such as wood and plaster should be properly sealed to prevent the vacuum pump

from sucking out any moisture or sawdust, loose plaster etc. The vacuum circuit may quickly become blocked

with dust or slurry if moulds are not properly sealed.

As the plastic cools after forming it will contract, gripping the tool tightly. If the tool has been made with

sloping sides and has a good surface finish it will release more easily. Where the draft angle must be kept to

a minimum a release agent may be used to assist release.

Sealed moulds will usually release more easily. Silicon based release agents may be used on more difficult

moulds. Silicon based release agents are rapidly absorbed by porous (unsealed) moulds, rendering them

ineffective.

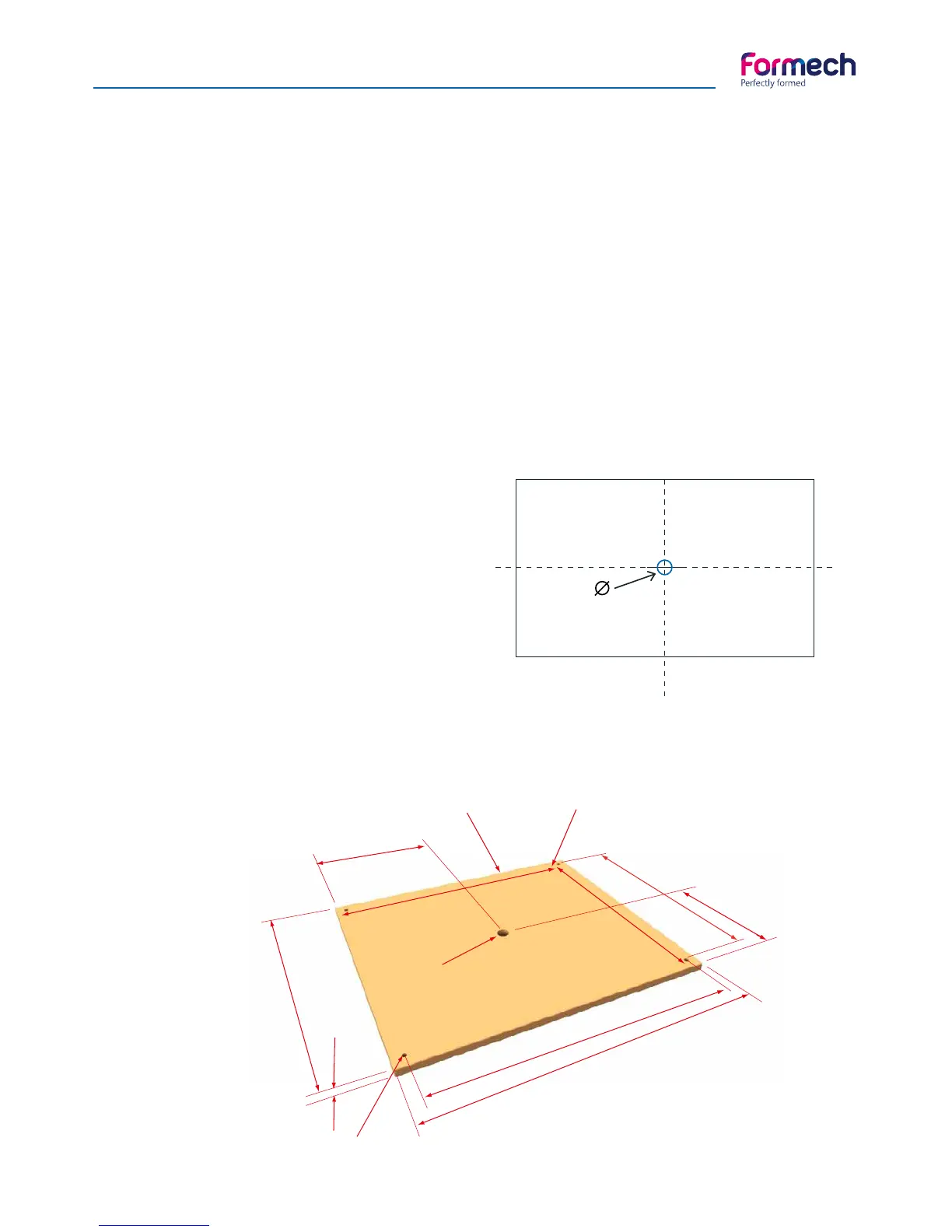

The baseboard can be made from either MDF or aluminium and needs to be 12.00mm (1/2”) thick. The

vacuum hole can be 19.00 – 20.00mm (3/4”) diameter and needs to be positioned in the center of the table.

19-20mm

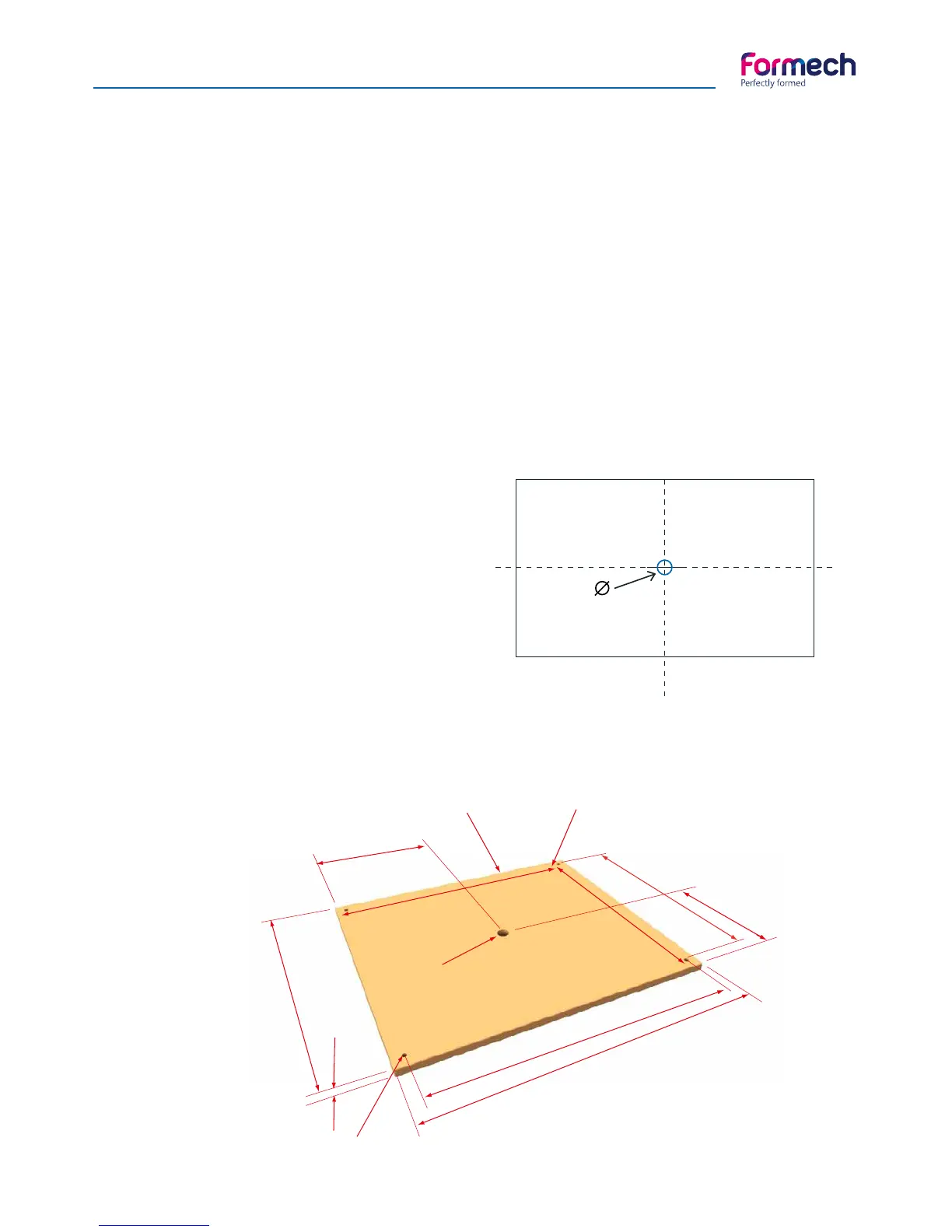

The baseboard has to be 4/5mm shorter in

both directions than the forming aperture

of the machine e.g. Forming aperture

482mm x 432mm = baseboard size

478mm x 428mm.

477mm (18.78”)

427mm (16.81”)

Make board 4mm ( 0.15”) smaller than reducing

window aperture front to back and left to right

213.5mm (8.40”)

12mm (1/2”)

238.5mm (9.38”)

Use four M6 cap head set screws

or M6 CSK machine screws x 19mm (3/4”)

long to bolt the board to the table (platen)

442mm (17.40”)

392mm (15.43”)

7mm (.275”) Diameter holes

R10mm (0.39”)

508DT and 508FS standard base board

R2mm (0.078”) radius on top edge

all round to stop MDF from flaking

508DT/FS standard baseboard

Make board 4mm (0.15“) smaller than full size

aperture front to back and left to right

Loading...

Loading...